- Lesson 1 – Getting Started

- Lesson 2 - Choosing a Robotic Platform

- Lesson 3 - Making Sense of Actuators

- Lesson 4 - Understanding Microcontrollers

- Lesson 5 - Choosing a Motor Controller

- Lesson 6 – Controlling your Robot

- Lesson 7 - Using Sensors

- Lesson 8 - Getting the Right Tools

- Lesson 9 - Assembling a Robot

- Lesson 10 - Programming a Robot

Making Sense of Actuators

Now that we learned about robotics in general in Lesson 1 and decided on the robot to make in Lesson 2, we will now choose the actuators that will make the robot move.

What is an actuator?

An "actuator" can be defined as a device that converts energy (in robotics, that energy tends to be electrical) into physical motion. The vast majority of actuators produce either rotational or linear motion. For instance, a "DC motor" is therefore a type of actuator.

Choosing the right actuators for your robot requires an understanding of what actuators are available, some imagination, and a bit of math and physics.

Rotational Actuators

As the name indicates, this type of actuator transforms electrical energy into a rotating motion. There are two main mechanical parameters distinguishing them from one another: (1) torque, the force they can produce at a given distance (usually expressed in N•m or Oz•in), and (2) the rotational speed (usually measured in revolutions per minute, or rpm).

AC Motor

AC (alternating current) is rarely used in mobile robots since most of them are powered with direct current (DC) coming from batteries. Also, since electronic components use DC, it is more convenient to have the same type of power supply for the actuators as well. AC motors are mainly used in industrial environments where very high torque is required, or where the motors are connected to the mains/wall outlet.

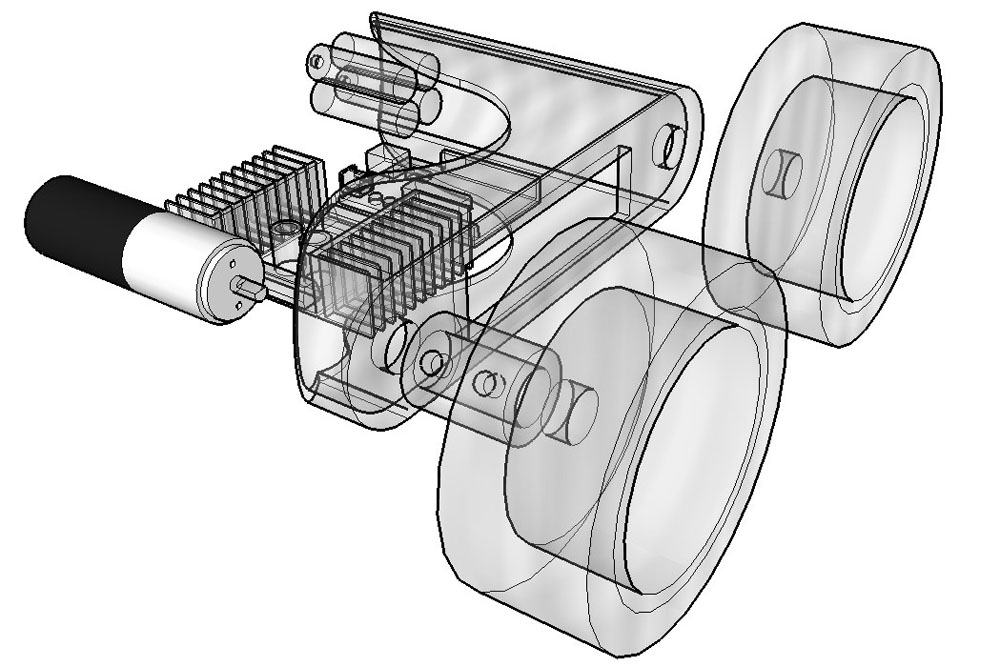

DC Motors

DC motors come in a variety of shapes and sizes although most are cylindrical. They feature an output shaft that rotates at high speeds usually in the 5 000 to 10 000 rpm range. Although DC motors rotate very quickly in general, most are not strong (low torque). In order to reduce the speed and increase the torque, a gear can be added. To incorporate a motor into a robot, you need to fix the body of the motor to the frame of the robot. For this reason, motors often feature mounting holes which are generally located on the face of the motor so they can be mounted perpendicularly to a surface. DC motors can operate in clockwise (CW) and counterclockwise (CCW) rotations. The angular motion of the turning shaft can be measured using encoders or potentiometers.

Geared DC Motors

A DC gear motor is a DC motor combined with a gearbox that works to decrease the motor’s speed and increase the torque. For example, if a DC motor rotates at 10 000 rpm and produces 0.001 N•m of torque, adding a 256:1 ("two hundred and fifty-six to one") gear down would reduce the speed by a factor of 256 (resulting in 10 000rpm / 256 = 39 rpm), and increase the torque by a factor of 256 (0.001 x 256 = 0.256 N•m). The most common types of gearing are "spur" (the most common), "planetary" (more complex but allows for higher gear-downs in a more confined space, as well as higher efficiency), and "worm" (which allows for very high gear ratio with just a single stage and also prevents the output shaft from moving if the motor s not powered). Just like a DC motor, a DC gear motor can also rotate CW and CCW. If you need to know the number of rotations of the motor, an “encoder” can be added to the shaft.

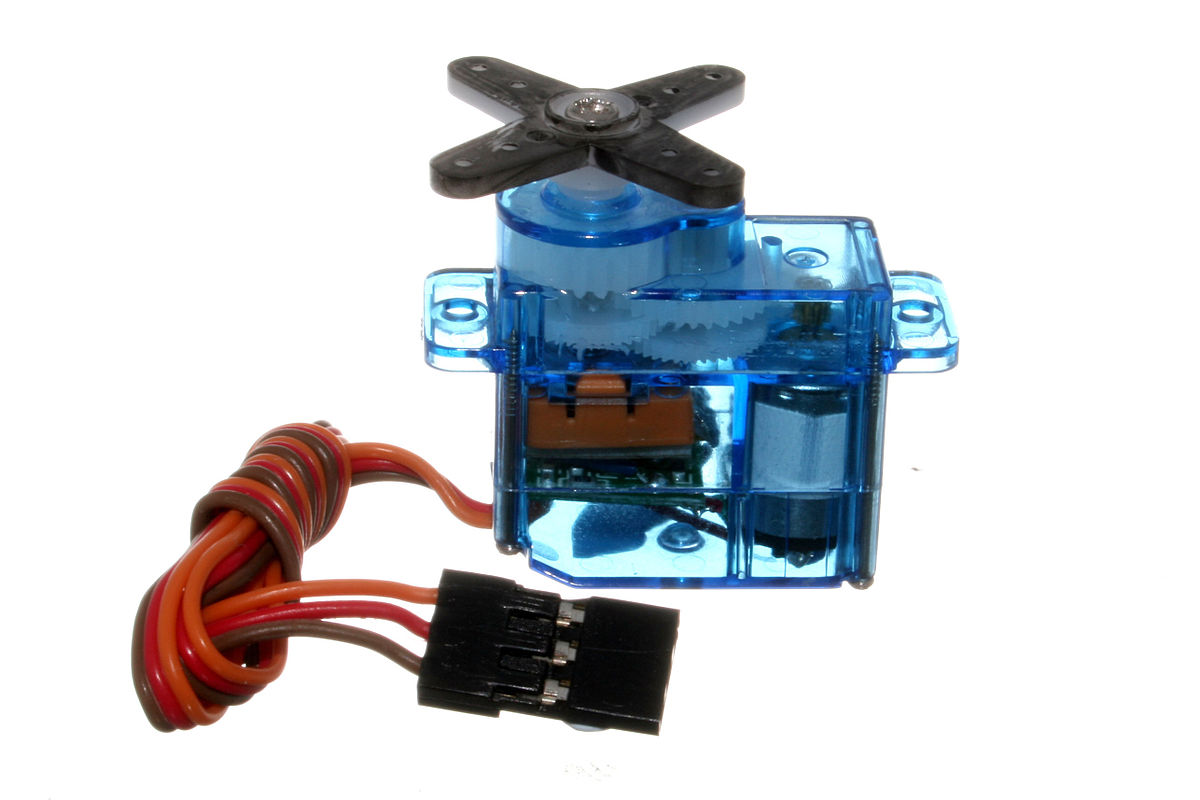

R/C Servo Motors

Industrial Servo Motors

An industrial servo motor is controlled differently than a hobby servo motor and is more commonly found on very large machines. An industrial servo motor is usually made up of a large AC (sometimes three-phase) motor, a gear down, and an encoder that provides feedback about the angular position and speed. These motors are rarely used in mobile robots because of their weight, size, cost, and complexity. You might find an industrial servo in a more powerful industrial robotic arm or very large robotic vehicles.

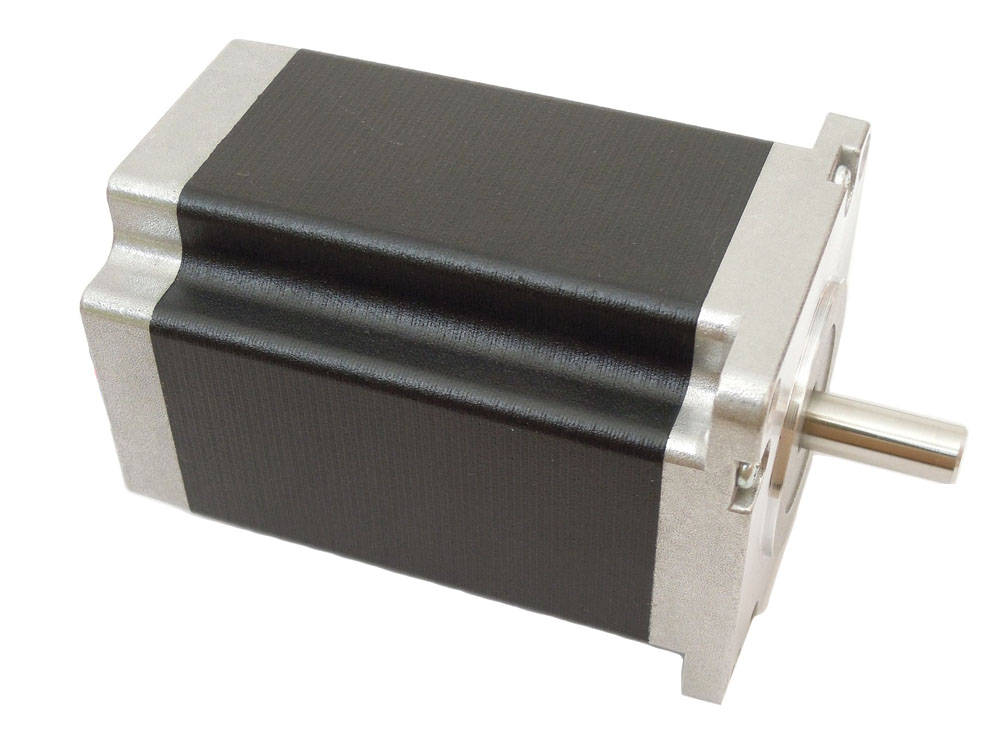

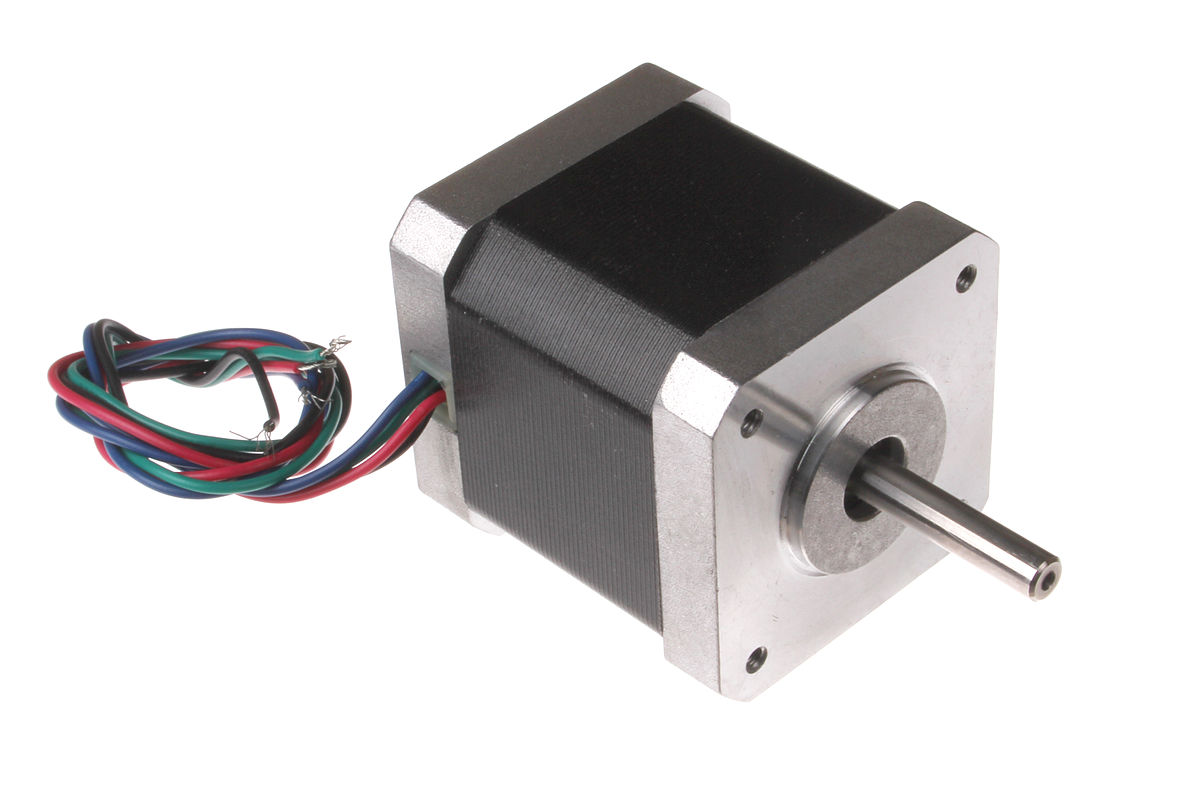

Stepper Motors

A stepper motor does exactly as its name implies; it rotates in specified “steps” (actually, specific degrees). The number of degrees the shaft rotates with each step (step size) varies based on several factors. Most stepper motors do not include gearing, so just like a DC motor, the torque is often low. Configured properly, a stepper can rotate CW and CCW and can be moved to a desired angular position. There are unipolar and bipolar stepper motor types. One notable downside to stepper motors is that if the motor is not powered, it’s difficult to be certain of the motor’s starting angle. Adding gears to a stepper motor has the same effect as adding gears to a DC motor: it increases the torque and decreases the output angular speed. Since the speed is reduced by the gear ratio, the step size is also reduced by that same factor. If the non-geared down stepper motor had a step size of 1.2 degrees, and you add a gear down of 55:1, the new step size would be 1.2 / 55 = 0.0218 degrees.

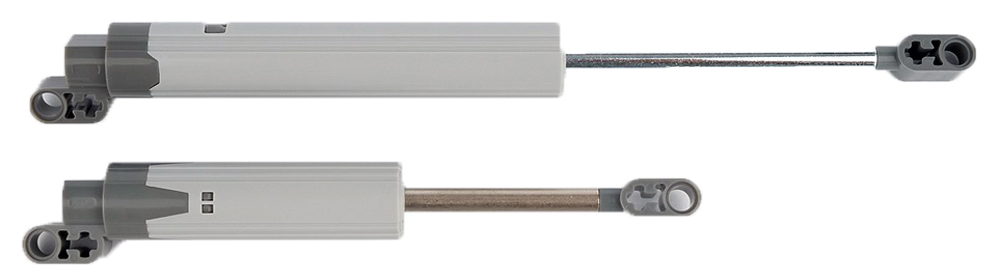

Linear Actuators

A linear actuator produces linear motion (motion along one straight line) and has three main distinguishing mechanical characteristics: the minimum and maximum distance the rod can move “a.k.a. the “stroke”, in mm or inches), their force (in Kg or lbs), and their speed (in m/s or inch/s).

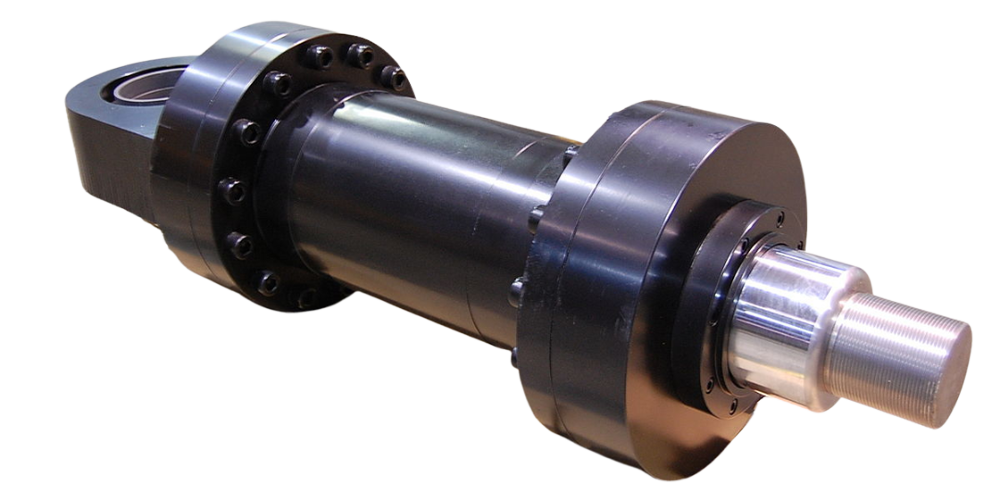

DC Linear Actuator

A DC linear actuator is often made up of a DC motor connected to a lead screw. As the motor turns, so does the lead screw. A traveler on the lead screw is forced either towards or away from the motor, essentially converting the rotating motion to a linear motion. Some DC linear actuators incorporate a linear potentiometer which provides linear position feedback. In order to stop the actuator from destroying itself, many manufacturers include limit switches at either end which cuts power to the actuator when pressed. DC linear actuators come in a wide variety of sizes, strokes, and forces.

Source: Rsteves00 - Wikipedia

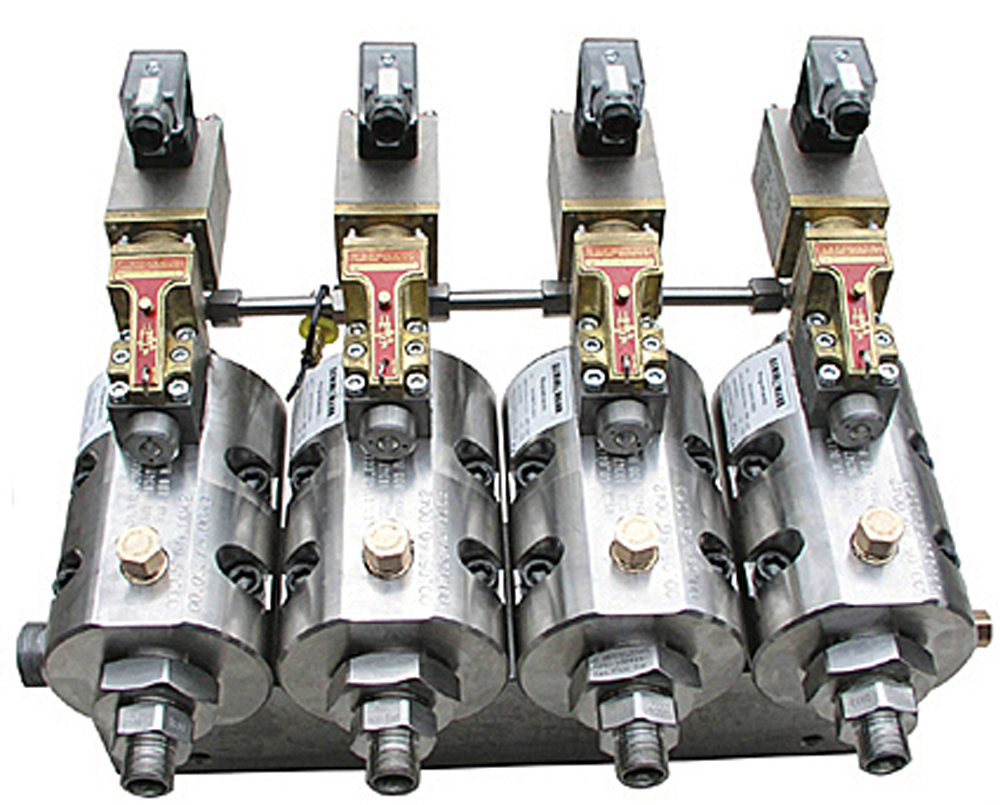

Solenoids

Solenoids are composed of a coil wound around a mobile core. When the coil is energized, the core is pushed away from the magnetic field and produces a motion in a single direction. Multiple coils or some mechanical arrangements would be required in order to provide a motion in two directions. A solenoid's stroke is usually very small but its speed is very fast. The strength depends mainly on the coil size and the current going through it. This type of actuator is commonly used in valves or latching systems and there is usually no position feedback (it’s either fully retracted or fully extended).

Source: Hammelmann Oelde - Wikipedia

Muscle wire

Muscle wire is a special type of wire that will contract when an electric current traverses it. Once the current is gone (and the wire cools down) it returns to its original length. This type of actuator is not very strong, fast, or provides a long stroke. Nevertheless, it is very convenient when working with very small parts or in a very confined space.

Pneumatic and Hydraulic

Pneumatic and hydraulic actuators use air or a liquid (e.g. water or oil) respectively in order to produce a linear motion. These types of actuators can have very long strokes, high force, and high speed. In order to be operated they require the use of a fluid compressor which makes them more difficult to operate than regular electrical actuators. Because of their high force speed and generally large size, they are mainly used in industrial environments.

Source: Rstom03 - Wikipedia

Choosing an Actuator

To help you with the selection of an actuator for a specific task, we have developed the following questions to guide you in the right direction. It is important to note that there are always new and innovative technologies being brought to market and nothing is set in stone. Also, note that a single actuator may perform very different tasks in different contexts. For instance, with additional mechanics, an actuator that produces linear motion may be used to rotate an object and vice versa (like on a car’s windshield wiper).

1. Is the actuator being used to move a wheeled robot?

Drive motors must move the weight of the entire robot and will most likely require a gear down. Most robots use “skid steering” while cars or trucks tend to use rack-and-pinion steering. If you choose skid steering, DC gear motors are the ideal choice for robots with wheels or tracks as they provide continuous rotation, can have optional position feedback using optical encoders, and are very easy to program and use. If you want to use rack-and-pinion, you will need one drive motor (DC gear is also suggested) and one motor to steer the front wheels). For stirring, since the rotation required is restricted to a specific angle, an R/C servo would be the logical choice.

2. Is the motor being used to lift or turn a heavyweight?

Lifting a weight requires significantly more power than moving a weight on a flat surface. The speed must be sacrificed in order to gain torque and it is best to use a gearbox with a high gear ratio and a powerful DC motor or a DC linear actuator. Consider using a system (either with worm gears or clamps) that prevents the mass from falling in case of a power loss.

3. Is the range of motion limited to 180 degrees?

If the range is limited to 180 degrees and the torque required is not significant, an R/C servo motor is ideal. Servo motors are offered in a variety of different torques and sizes and provide angular position feedback (most use a potentiometer, and some specialized ones use optical encoders). R/C servos are used more and more to create small walking robots.

4. Does the angle need to be very precise?

Stepper motors and geared stepper motors (coupled with a stepper motor controller) can offer very precise angular motion. They are sometimes referred to as servo motors because they offer continuous rotation. However, some high-end digital servo motors use optical encoders and can offer very high precision.

5. Is the motion in a straight line?

Linear actuators are best for moving objects and positioning them along a straight line. They come in a variety of sizes and configurations. Muscle wire should be considered only if your motion requires very little force. For very fast motion, consider pneumatics or solenoids, and for very high forces, consider DC linear actuators (up to about 500 pounds) and then hydraulics.

Source: 42100 Liebherr R9800 - Wikipedia

Tools

In order to compute the strength (or torque), and speed required for your application, many (rather complex) computations are required involving the physics of the machine to be created. In order to simplify the design process, we have put together a few tools that can help you out.

- DC Drive Motor Selector (useful for robots with wheels or tracks). Also, consult the Drive Motor Sizing Tutorial for further details.

- Robot Leg Torque Tutorial

- Robot Arm Torque Calculator

Practical Example

In lesson 1 we determined the objective of our project would be to get a better understanding of mobile robots while keeping the budget to about $200 to a maximum of $300. In lesson 2 we decided we wanted a small tank (on tracks) that could operate on top of a desk.

First, let us determine the type of actuators that would be required by answering the five aforementioned questions:

- Is the actuator being used to move a wheeled robot? Yes. A DC gear motor is the suggested type of actuator and skid steering is appropriate for a tank, which means that each track will need it's own motor.

- Is the motor being used to lift or turn a heavyweight? No, a desktop rover should not be heavy.

- Is the range of motion limited to 180 degrees? No, the wheels need to run continuously.

- Does the angle need to be precise? No, our robot does not require positional feedback.

- Is the motion in a straight line? No, since we want the robot to turn and move in all directions.

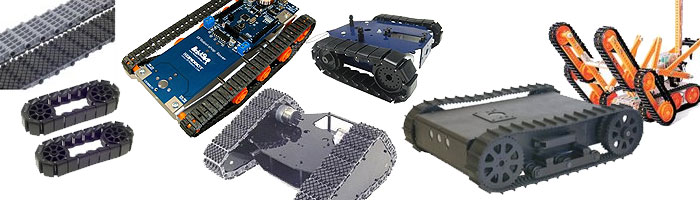

A search online shows that there are not too many track systems intended for small robots, which in itself would restrict which motors we could consider.

The Currently Available Track Systems

At 2" and 3" wide, the Lynxmotion tracks are more intended for medium-sized robots, so we’ll omit them. The price does fall within the budget though.

The Vex Tank Tread Kit is definitely a good option, but it would restrict us to one specific motor.

The Tamiya Track and Wheel Set is definitely a good option and would limit our choices to Tamiya motors and gearboxes. This would also be within the budget.

There are several Johnny Robot Track Kits, one for a Hitec continuous rotation servo (which is essentially a gear motor in a servo’s body) another for a Futaba continuous rotation servo, one for Tamiya motors, and another for Pololu or Solarbotics motors. This is definitely a good option and also within our budget. Mainly because of aesthetic and motor compatibility reasons, we are going to stick with this choice.

There is always the option of hacking a toy such as an R/C tank and converting it into a robot. This option would also give us compatible motors, however, the objective is to design our own robot and not hack another product.

Computing the motor requirements

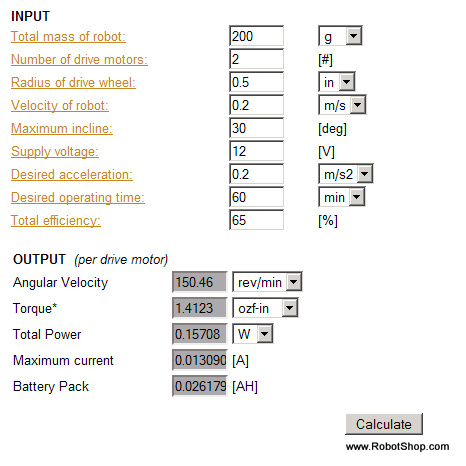

The next step is to fill out the DC Drive Motor Selector Tool, using approximate values.

Data Details

- Total mass of robot:200 g should include everything: motors, frame, batteries, and all.

- Number of drive motors: Two motors are required for skid steering.

- Radius of the drive wheel: from 0.5” to about 1” should be an appropriate size for a desktop robot.

- Velocity of the robot:0.2 m/s would be nice for a desktop robot.

- Maximum incline: Climbing some books would be cool, let us choose 30 degrees.

- Supply Voltage: Uncertain at the moment, so we choose the default 12 V

- Desired Acceleration: Not sure, so choose default 0.2 m/s2

- Desired operating time: 30 minutes is reasonable between charges.

- Total efficiency: Not sure, so we choose the default 65%

Using 0.5 as the wheel radius we obtain 150 rpm @ 1.4 oz-in. When using 1”, the calculator provides 75rpm @ 2.8 oz-in.

Selecting the Motor

Thus, the motors we are looking for must turn at approximately 150 rpm and provide roughly 1.4123 oz-in of torque. There are many motors available that fit the Johnny Robot Track Kit: The Solarbotics GM8 and GM9 feature 70 rpm @ 43 oz-in and 66 rpm at 43 oz-in respectively. Both sell for $5.46 each. All Tamiya gearbox ad motor combinations sell for approximately $11 and up and provide a wide range of torques and speeds. Hitec continuous rotation servo and Futaba continuous rotation servos sell for $17 and $14 respectively. In the end, we opted to use a pair of Solarbotics GM9 in order to use skid-drive, mainly because of their low cost. It is important to note that although the calculator specified we needed about 150rpm, we chose the motor anyway, knowing it would move at about half the original (desired) velocity. The torque produced by this motor is significantly greater than what we needed, which means it can carry additional weight or climb stepper angles.

For further information on learning how to make a robot, please visit the RobotShop Learning Center. Visit the RobotShop Community Forum in order to seek assistance in building robots, showcase your projects or simply hang out with other fellow roboticists.