- Lesson 1 – Getting Started

- Lesson 2 - Choosing a Robotic Platform

- Lesson 3 - Making Sense of Actuators

- Lesson 4 - Understanding Microcontrollers

- Lesson 5 - Choosing a Motor Controller

- Lesson 6 – Controlling your Robot

- Lesson 7 - Using Sensors

- Lesson 8 - Getting the Right Tools

- Lesson 9 - Assembling a Robot

- Lesson 10 - Programming a Robot

Following the first lesson, you now have a basic understanding of what a robot is and what current robots normally do. Now, it is time to decide on the type of robot you are going to build. A custom robot design often starts with a "vision" of what the robot will look like and what it will do. The types of robots possible are unlimited, though the more popular are:

- Land wheeled, tracked, and legged robots

- Aerial planes, helicopters, and blimps

- Aquatic boats, submarines, and swimming robots

- Misc. and mixed robots

- Stationary robot arms, and manipulators

This lesson is intended to help you decide what type of robot to build to best suit your mission. Since you have brainstormed on what tasks or functions you want it to accomplish (after lesson 1), you can now choose the type of robot that will best suit your needs. Below, you will find a description of all the major robot types.

Land

Land-based robots, especially wheeled ones, are the most popular mobile robots among beginners as they usually require the least investment while providing significant exposure to robotics. On the other hand, the most complex type of robot is the humanoid (akin to a human), as it requires many degrees of freedom and synchronizes the motion of many motors, and uses many sensors.

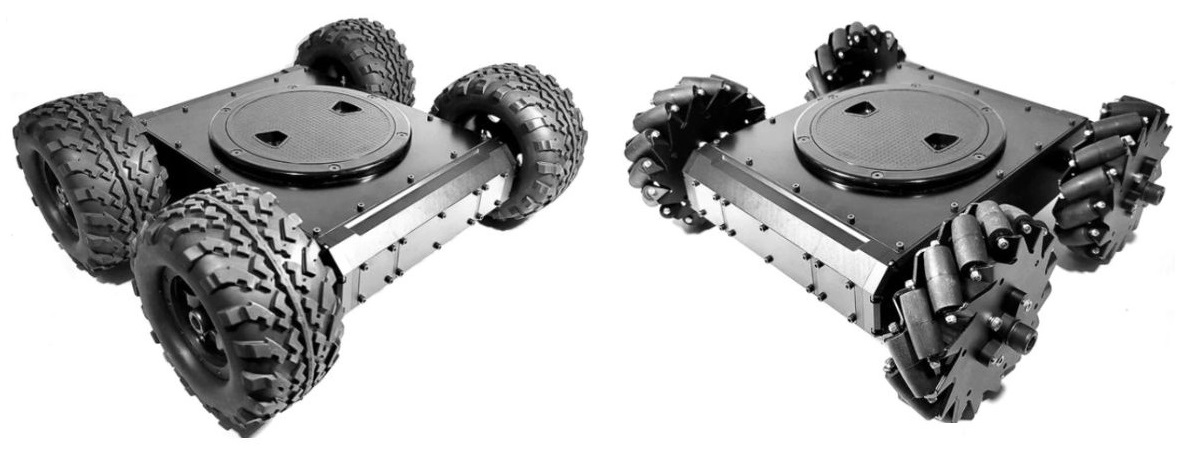

Wheeled Robots

Wheels are by far the most popular method of providing mobility to a robot and are used to propel many different-sized robots and robotic platforms. Wheels can be just about any size, from a few centimeters up to 30 cm and more. Tabletop robots tend to have the smallest wheels, usually less than 5 cm in diameter. Robots can have just about any number of wheels, although 3 and 4 are the most common. Normally a three-wheeled robot uses two wheels and a caster at one end. More complex two-wheeled robots may use gyroscopic stabilization. It is rare that a wheeled robot uses anything but skid steering (like that of a tank). Rack and pinion steering such as that found on a car require too many parts and its complexity and cost outweigh most of its advantages. Four and six-wheeled robots have the advantage of using multiple drive motors (one connected to each wheel) which reduces slip. Also, omnidirectional wheels or mecanum wheels, used properly, can give the robot significant mobility advantages. A common misconception about building a wheeled robot is that large, low-cost DC motors can propel a medium-sized robot. As we will see later in this series, there is a lot more involved than just a motor.

Advantages

- Usually low-cost compared to other methods

- Simple design and construction

- Abundance of choice

- Six wheels or more rival a track system

- Excellent choice for beginners

Disadvantages

- May lose traction (slip)

- Small contact area (only a small rectangle or line underneath each wheel is in contact with the ground)

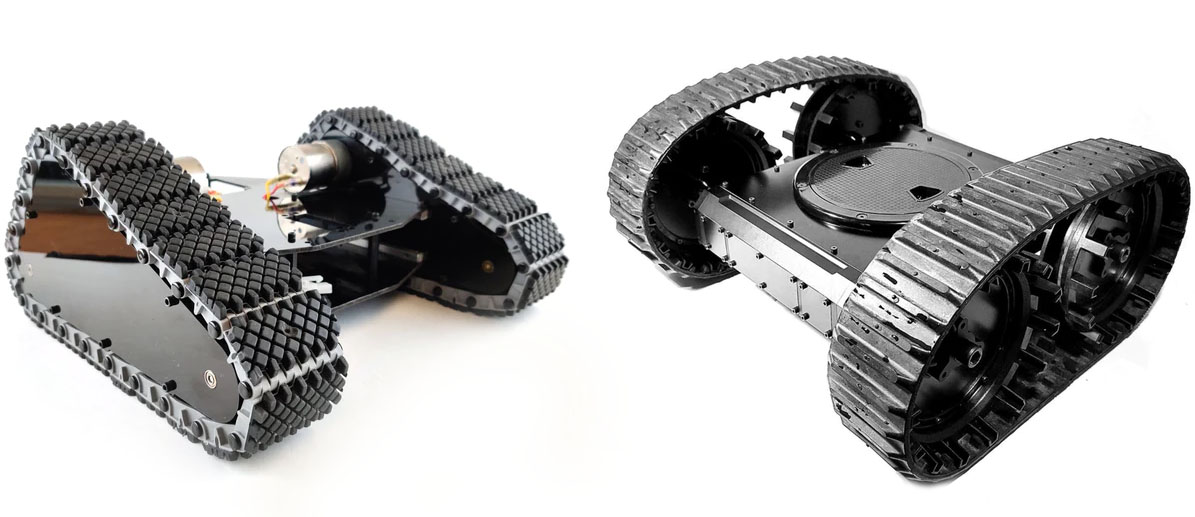

Tracked Robots

Tracks (or treads) are what tanks use. Although tracks do not provide added "force" (torque), they do reduce slip and more evenly distribute the weight of the robot, making them useful for loose surfaces such as sand and gravel. Also, a track system with some flexibility can better conform to a bumpy surface. Finally, most people tend to agree that tank tracks add an "aggressive" look to the robot as well.

Advantages

- Constant contact with the ground prevents slipping that might occur with wheels

- The evenly distributed weight helps your robot tackle a variety of surfaces

- Can be used to significantly increase a robot’s ground clearance without incorporating a larger drive wheel

Disadvantages

- When turning, there is a sideways force that acts on the ground; this can cause damage to the surface the robot is being used on, and cause the tracks to wear

- Not many different tracks are available (the robot is usually constructed around the tracks)

- Drive sprocket might significantly limit the number of motors that can be used.

- Increased mechanical complexity (idler placement and number, # of links) and connections

Legs

An increasing number of robots use legs for mobility. Legs are often preferred for robots that must navigate on very uneven terrain. Most amateur robots are designed with six legs, which allow the robot to be statically balanced (balanced at all times on 3 legs); robots with fewer legs are harder to balance. The latter requires "dynamic stability", meaning that if the robot stops moving mid-stride, it might fall over. Researchers have experimented with monopod (one-legged "hopping") designs, though bipeds (two legs), quadrupeds (four legs), and hexapods (six legs) are the most popular.

Advantages

- Closer to organic or natural motion

- Can potentially overcome large obstacles and navigate very rough terrain

Disadvantages

- Increased mechanical, electronic, and coding complexity (not the easiest way to get into robotics).

- Lower battery size despite increased power demands

- Higher cost to build

Air

AUAV (Autonomous Unmanned Aerial Vehicle) are very appealing and are entirely within the capability of many robot enthusiasts. However, the advantages of building autonomous unmanned aerial vehicles, especially if you are a beginner, have yet to outweigh the risks. When considering an aerial vehicle, most hobbyists still use existing commercial remote-controlled aircraft. On the professional side, aircraft such as the US military Predator were initially semi-autonomous though in recent years Predator aircraft have flown missions autonomously.

Advantages

- Remote-controlled aircraft have been in existence for decades (so there is a large community, at least for the mechanics)

- Excellent for surveillance

Disadvantages

- The entire investment can be lost in one crash.

- Limited robotic community to provide help for autonomous control

Water

An increasing number of hobbyists, institutions, and companies are developing unmanned underwater vehicles. There are many obstacles yet to overcome to make underwater robots attractive to the wider robotic community though in recent years, several companies have commercialized pool cleaning "robots". Underwater vehicles can use ballast (compressed air and flooded compartments), thrusters, tail, and fins, or even wings to submerge. Other aquatic robots such as pool cleaners are useful commercial products.

Advantages

- Most of our planet is water, so there is a lot to explore and discover

- Design is almost guaranteed to be unique

- Can be used and/or tested in a pool

Disadvantages

- The robot can be lost in many ways (sinking, leaking, entangled...)

- Most electronic parts do not like water (also consider water falling on electronics when accessing the robot after a dive)

- Surpassing depths of 10m or more can require significant research and investment

- Very limited robotic community to provide help

- Limited wireless communication options

Miscellaneous and Hybrid Combinations

Your idea for a robot may not fall nicely into any of the above categories or may be comprised of several different functional sections. Note again that this guide is intended for mobile robots as opposed to stationary or permanently fixed designs (other than robotic arms and grippers). It is wise to consider when building a hybrid design, using a modular design (each functional part can be taken off and tested separately). Miscellaneous designs can include hovercraft, snake-like designs, turrets, and more.

Advantages

- Designed and built to meet specific needs

- Multi-tasking and can be comprised of modules

- This can lead to increased functionality and versatility

Disadvantages

- Possible Increased complexity and cost

- Oftentimes, parts must be custom designed and built

Arms & Grippers

Although these do not fall under the category of mobile robotics, the field of robotics essentially started with arms and end-effectors (devices that attach to the end of an arm such as grippers, electromagnets, etc). Arms and grippers are the best way for a robot to interact with the environment it is exploring. Simple robot arms can have just one motion, while more complex arms can have a dozen or more unique degrees of freedom.

Advantages

- Very simple to very complex design possibilities

- Easy to make a 3 or 4-degree-of-freedom robot arm (two joints and turning base)

Disadvantages

- Stationary unless mounted on a mobile platform

- The cost to build is proportional to the lifting capability

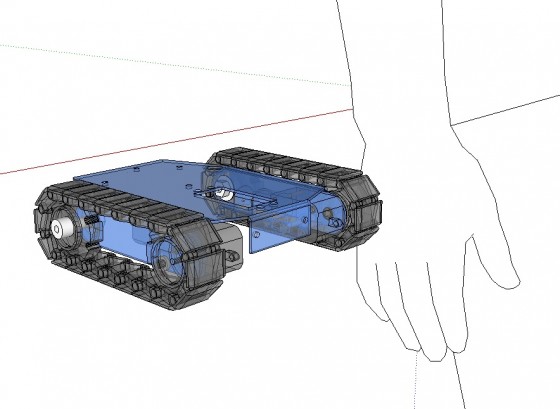

In our case, we have opted for building a robot that will provide the maximum exposure to robotics. A programmable tracked platform that can accommodate a variety of sensors and grippers seems ideal in this case, especially since we consider tank tracks are far cooler than wheels. In order to keep the costs down, we opted to build a small desktop robot that will be able to roam indoors and on tabletops. We also have taken into consideration the fact that there are not many tracks available, and to keep things simple, we’ll only consider a single drive sprocket and single idler sprocket system, this should not be a problem since the robot will be very lightweight. The preliminary CAD below summarized the features described so far.

Next, we will be choosing the right actuators (e.g. motors) for your robot.

For further information on learning how to make a robot, please visit the RobotShop Learning Center. Visit the RobotShop Community Forum in order to seek assistance in building robots, showcase your projects or simply hang out with other fellow roboticists.