i’m thinking of building a 18 DOF biped project

but it ill be a long time to finish this project

because i have very little money (hey i’m only 12)

so before i get started i want to know what you think

I have not actually begun to undertake a biped project (yet), but if you’re operating with a limited budget, you might find it both more fun and educational to consider taking an incremental approach to building a biped from the Servo Erector Set, rather than going for a full-blown bot all in one punch.

As you can see from browsing these forums and the main website, there are a mind-boggling number of different designs that can be achieved through the use of the SES pieces, a single SSC-32 module, and some time. You could easily start with a 4-servo biped, then add two more servos for a 6-servo BRAT design. Add a few more servos, and you can build the equivalent of a Scout or Lynx-209 biped. Keep adding, and you can eventually work your way up to a full humanoid biped. Along the way, you can tinker and play with other designs, taking advantage of the SES pieces’ adaptability and modular design. Who knows? Along the way, you might discover some arrangement of joints and “bones” that works better for you than the usual layout. The SES brackets and interconnecting pieces are remarkably flexible in their design, and should provide you with no end to the possibilities.

Have fun, and keep us updated on your experiments. We love to hear what others are doing out there, and sharing ideas.

im going to have to go with seamus

try building a biped a little bit at a time, it will help in learning it faster and you can resuse the SES brackets in other projects

btw, i understand from where your coming from about the money problem, im in the same boat, only 15, along with many others in this forum who are 18 and under

well i do have to agree with you guys

but i forgot to tell you that i’m using micro servos

and the not expensive thing in this project is

that im building a servo controller from scratch

it will be hard but iv been working with electronics

since i was 3 years old (obeyesly i didn’t know how to read at

that time so i used to take video players apart

but what i’m asking is if you think its a good idea

like me

like me

, well, you’ll need to make and design you own brackets, which will probably be expensive, also the mirco servos might not be able to handle that kinda of stress

, well, you’ll need to make and design you own brackets, which will probably be expensive, also the mirco servos might not be able to handle that kinda of stress  , not to mentions the battery pack and stuff too, but if you make your own designs, then you could probably hit brokenlaser up about cutting them, he could help you out with the design too

, not to mentions the battery pack and stuff too, but if you make your own designs, then you could probably hit brokenlaser up about cutting them, he could help you out with the design too

and about the servo controller…all i can say is good luck with that

i do have erecter sets

do you think that those brackets

will work

with the micro servos? no they will not work, they are MUCH smaller then standerd sized servos

no i meen the real erecter sets (the ones that arent made by lynxmotion)

, idk, probably not, because the holes are different and unless you gonna want to bend everything, then it wont work, plus the servos horns would need their own piece of metal to connect (there own hole pattern)

, idk, probably not, because the holes are different and unless you gonna want to bend everything, then it wont work, plus the servos horns would need their own piece of metal to connect (there own hole pattern)

There’s always sheet metal and tin snips…

lol, well, i wish him the best of luck…cause that can get VERY messy

Yes, it can.

But it really can be done, and done well if you take your time.

I made these waist and feet brackets with a hacksaw and a hand drill.

img373.imageshack.us/img373/8558/minimidgetbottomfootjpgbj4.th.jpg

I used a steel brush to get that nice brushed effect, and vioila!

thanks and i

realy like how you put

touch sensors on the toes

could you brakets just for mini

servos 8)

all right last night i came up with a little idea

i was going to wait to get a drill but i got

a better plan now. so what i did for the micros and brakets

is i melted a plastec spacer onto the brakets and

that screw wouldent fall through the braket.

all right so i can’t realy expalain it but i will show you an image of

what i did in a few hours (maby even tomorrow) but the thing is that it worked

hello agan

i found a very

cheap servo controller and it is also the smallest

pololu.com/products/pololu/0207/big_view.html

see i told you it could do it

To use this controller, you would need four of them daisy chained to control 32 servos. This would cost you $71.80 plus shipping/handling. Lynxmotion sells the SSC-32 (controls 32 servos) for $39.95.

If you only ever expect to need to control 8 servos for your project, then the Pololu controller may well be the best choice. However, if you think you will need to control more servos in the future, it may not be the best choice. Be careful before you lock yourself into using a specific controller and consider the true cost.

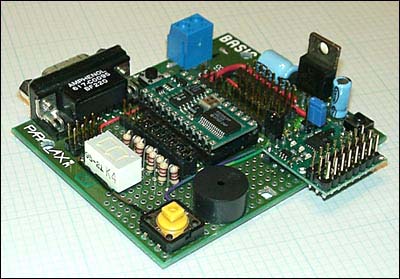

The SSC-32 is also very small and can be piggy backed with an ATOM Bot Board and others as required for a given application.

What software is available for the Pololu controller? A nice visual sequencer is available for the SSC-32. I notice the website says the Pololu controller is compatible with the MiniSSC, which may be good if that one is what the SSC-32 controller is based on. Do some more detailed checking.

Going for the cheapest solution is not always the best deal, especially over the long run. You have to think and plan ahead and decide where you want to go with a project. Then you can decide what the best hardware to get you there will be. For some things, this Pololu controller may be ideal since multiple controllers can be daisy chained along with their motor controllers. But, as I said, please be careful before locking yourself into a product line and consider the longer term cost of your project. There will probably be upgrades you’ll want to do to your project.

Usually when I pick something based only on getting the lowest price, I end up regretting the choice at some point. This is not always going to be true, but it has been true more often than not for me.

8-Dale

I do agree with all of the above points, though as you say, if you don’t plan to be driving more than just a handful of servos, it can make a handy addition to a project, particularly if space is at a premium, since the Pololu controller is literally less than an inch square.

In this case, it’s the brain board for a small testbed rover, which can reasonably expect only two servo signals for drive, one for aiming a sensor assembly, and maybe one or two more for assorted other purposes. As you can see, I’d pretty much run out of room on the little protoboard area (I must be done - I’ve run out of space to put anything else), and the servo controller is hard-mounted as a “balcony” off one side, hanging on for dear life. It works well, if a bit awkward-looking.

One negative aspect that I have encountered over and over again in my experiments: The broader your base - be it in motor controllers, micros, LCD modules, IDEs, etc. - the more there is to remember. I find myself constantly referring back to my reference binders (everyone keeps 3-ring binders full of instruction manual printouts, don’t they?) in order to confirm that the command that I’m sending to a given module is indeed a command for that particular module, and not a similar one from a different manufacturer.

If you’re absolutely certain that for a given project, you will never conceivably use more than eight or sixteen servos, then perhaps the little controller might be the one you want to use. In your original post though, you said that you’re working up to an 18-DOF biped, and in order to reach that goal, you’ll need to purchase three Pololu controllers. After purchasing your third Pololu controller (for axes 17-24), you’ll have spent more on servo control than if you’d just gone with an SSC-32 to begin with.

Again, there are questions of form-factor to consider, as well - the SSC-32 stacks well with the ABB and other boards in the Lynxmotion lineup, making it very easy to mount all of your electronics together and keep wires short and unstressed. The Pololu controller is very small, and the mounting holes are not large enough to accept a 4-40 screw. It’s very light, too. Unless you find someplace to rigidly mount it, the servo and signal wires will tend to drag it around, and the more movement you have in your wires, the more you risk breaking the conductors, and/or having a connector work itself free from a header.

I’m not arguing in favor of or against either particular model - I use both the Pololu Micro and the SSC-32 in my projects - each has its advantages and disadvantages for a given application. As LinuxGuy said though, weigh all of your options before you commit to any particular one, and be sure that you look down the road to future needs, not just the immediate problem.

Don’t like getting into these sort of chats, but there is a point I thought should be made. The SSC-32 has the group move feature that makes multiaxis robots very easy to control. Daisy chaining several Pololu or other servo controllers will not provide this functionality.

Oh, yeah!

Heh. Forgot that that wasn’t available on the other one, because I’m usually just commanding one servo at a time, or two within a couple of commands of each other.

Another good reason to go with the SSC-32 if you’re looking to work towards a biped.