b2.doc (70144Bytes)

Hi roboticists! This is one of the new brackets that I've made for the Godo's re-build and as I liked the final result, I've decided to share with you.

Well... to begin, let's go to the list of materials and necessary tools.

MATERIALS:

- 2mm Polystyrene sheets (or other plastic of your preference);

- A4 paper;

- Instant adhesive (I've used Loctite Super Bonder);

- Masking tape;

- Sandpaper.

TOOLS:

- Scissors;

- Sharp blade;

- Steel ruler;

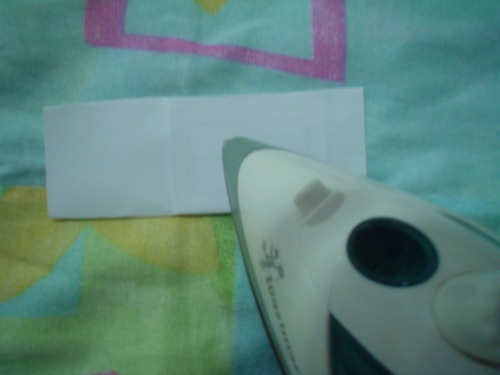

- Iron;

- Drill.

Let's go to work!

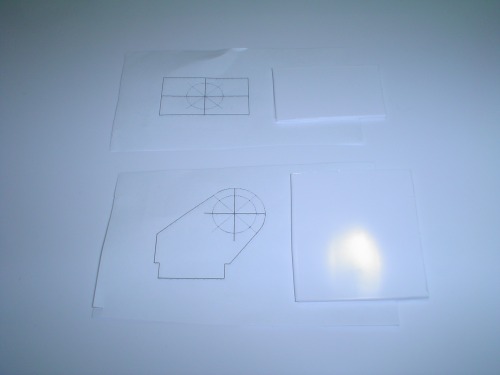

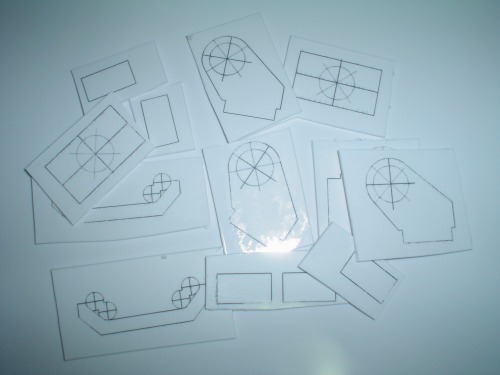

Initially, we print the template available for download above in a laser print. According to their need to use, you must print it in mirror.

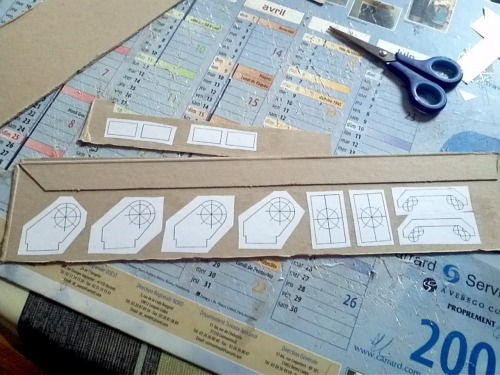

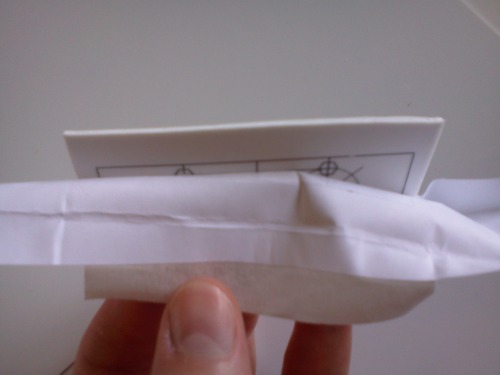

Cut small parts of the template one by one, and also polystyrene sheet parts in equivalent size.

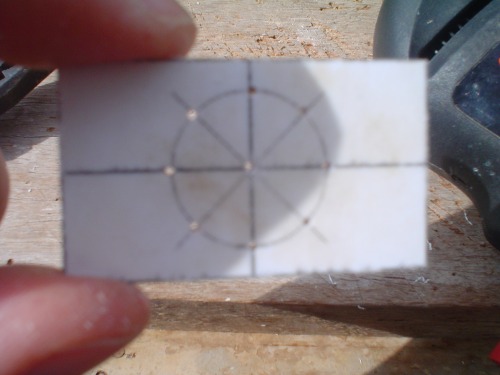

Glue the small piece of paper with the printed side in contact with polystyrene.

This is the time of the iron goes into action. As the laser printer ink is composed of tiny particles of plastic, the ink detaches and sticks with the heating back on the polystyrene. The temperature should not be too high. Start with low temperature and then increase, if necessary.

Pass sometimes a side to side. Take a look if the ink has adhered to the polystyrene. If it’s already stuck a small part that forms the desired design, that’s good.

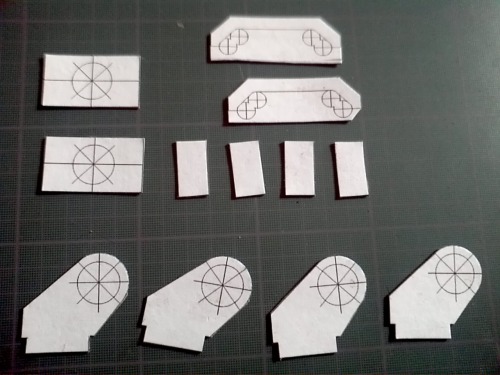

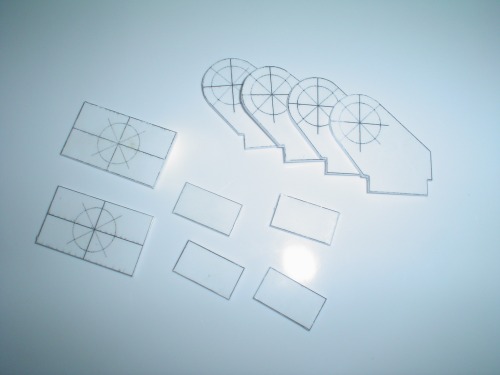

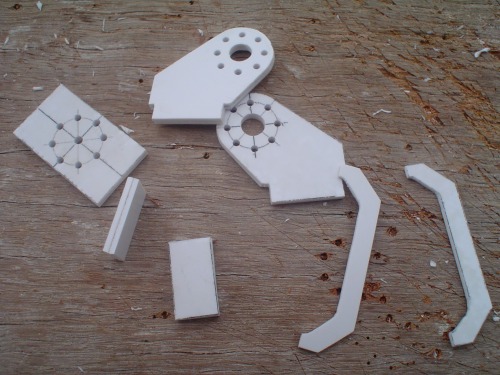

Now, is the time to cut and make holes.

With the assistance of the steel ruler, cut with the sharp blade which indicate the lines. With a slight cut is already possible to break easily. Rounded parts can be easily cuted with the scissors.

Then we make holes where indicated. Initially with a 1mm drill bit to mark and then drill with the desired final measure.

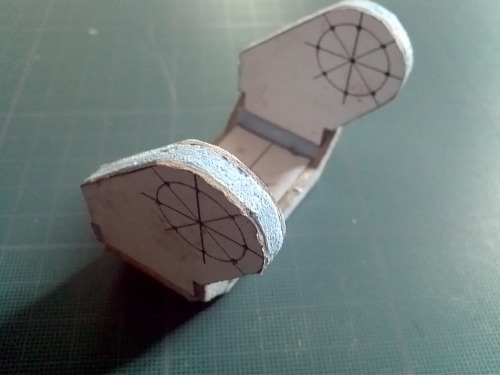

With all the parts cuted and holed, it’s time to join them all with the instant adhesive.

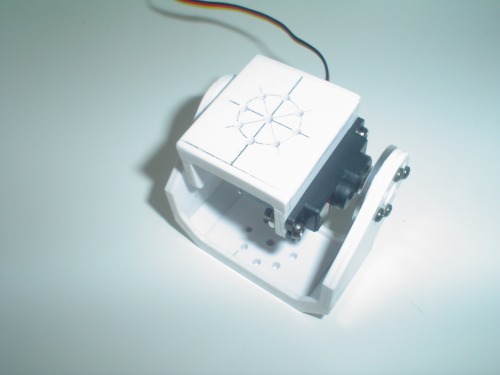

After everything is together, give finishing with sandpaper.

And is finalized your homemade servo bracket!

I am impressed. Nice work.

I am impressed. Nice work.