RobotShop releases Lynxmotion's new smart servo motors

Lynxmotion has just released their new line of smart servo motors, intended to make smart servo technology accessible to all. So what are they all about, how do they work and how can they be used to create robots? Take a look at the video below:

New Lynxmotion Smart Servo (LSS) Motors

Lynxmotion was a pioneer in hobby robots which were based on RC servo motors. These robots evolved to include more modular components and eventually became a robotic building system known as the “Servo Erector Set” (S.E.S.). RobotShop’s intention was to not only create a smart servo which was compatible with this system, but to make the technology accessible and easy to use by all robot builders.

“These smart servo motors were designed to form the foundation of the next generation SES modular robotic construction system and allow for an evolution of the many robotic kits in the portfolio.” Indicated Coleman Benson, R&D Project Manager at RobotShop. “The Lynxmotion Smart Servo (LSS) incorporate the top of the line technology in their category and we intend to build on this platform and extend to other segments of the robotics market.”

The new servos all include 360-degree absolute positioning, multi-turn virtual positioning, RC and serial control, a variety of sensor outputs, many mechanical connection points and more. Unlike existing smart servos, the custom communication protocol is “human readable”, making it easy to use and understand.

With new technology like 5G, powerful processors and artificial intelligence, the robotics market is destined to boom and become a predominant industry. Smart motors are the “muscles” of robots and RobotShop intends to position Lynxmotion as a leading brand.

Read the official press release on PR Web.

Making Smart Servo Technology Easy to Use

LSS Communication Protocol

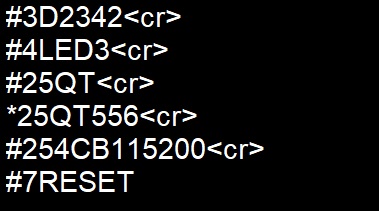

The LSS serial communication protocol was designed to be easy to read, but just how does it work?

"Action": Tell the servo to do something

Servo with ID number 5, please move to 150.0 degrees, ok? … becomes ... Servo #5, move to Degree 150.0, ok? Command: #5D1500<cr>

Therefore the following command can be easily interpreted: #3D2000<cr> ... which would mean ... Servo with ID #3, please move to 200.0 degrees, ok?

"Query": Ask the servo a question

Servo with ID number 4, please tell me your temperature, ok? … becomes ... Servo #4, please Query your Temperature and tell me, ok? Command: #4QT<cr>

The servo replies with the same query and adds the number, so servo #4 might reply: *4QT450<cr> … indicating it is at 45.0 degrees (Celsius)

"Configuration": Change the servo’s settings

An LSS servo’s configurations can range from the LED color to how the servo decelerates. For example, to set the servo number 7's maximum speed (in RPM) to 48, the command would be:

#7CSR48<cr> .... which is servo #7 Configure Speed in RPM to 48.

Learn more about the LSS Communication Protocol on the Lynxmotion Wiki.

Mechanics

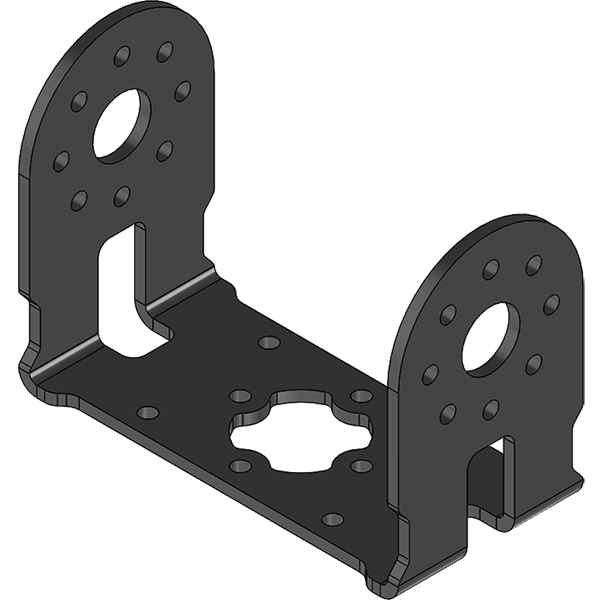

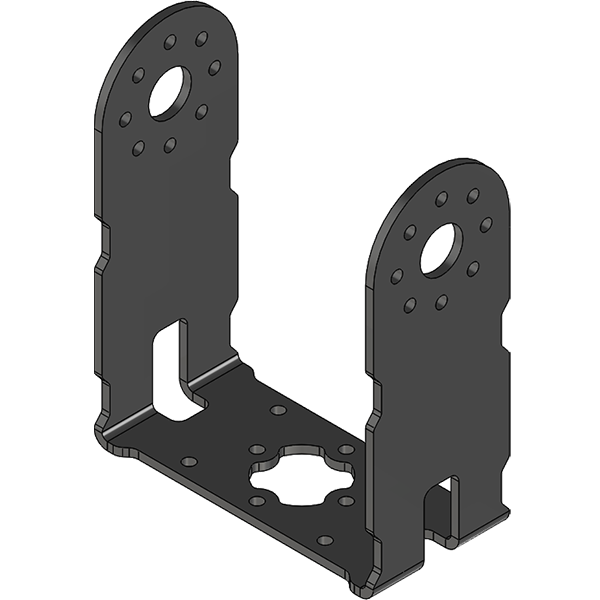

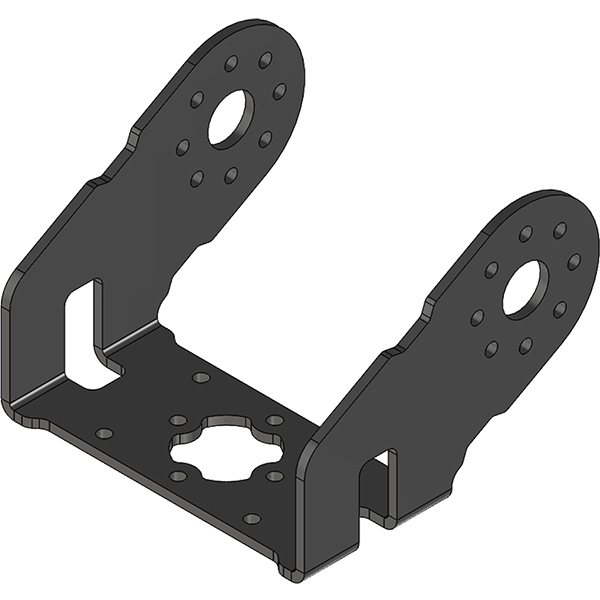

LSS Mounting Points

The LSS actuators are intended to be incorporated into the mechanical structure of a robotic creation and include many, many mounting points. For example, the single-wide LSS bracket can be mounted in any of six positions around the servo, while the double-wide LSS bracket can be mounted to either side:

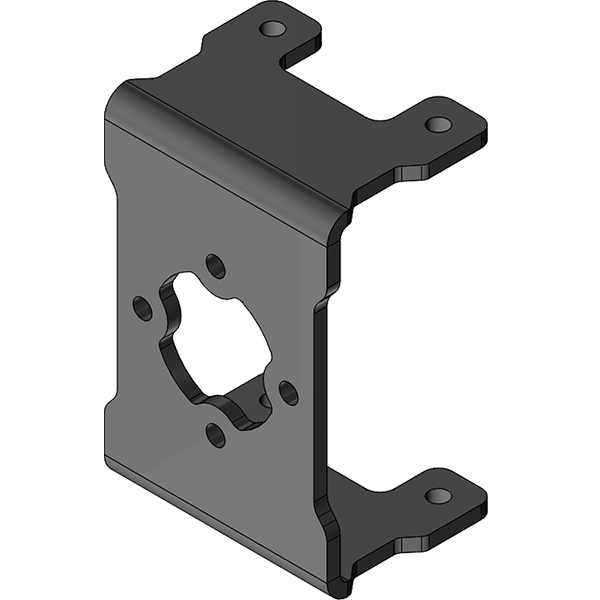

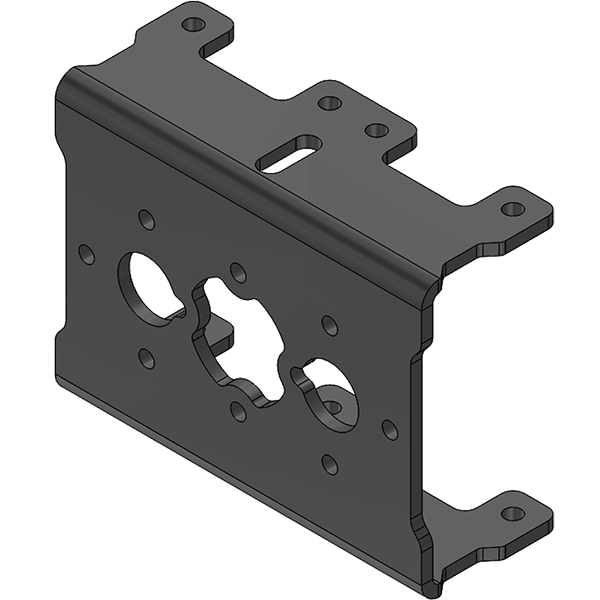

SES Connection Pattern & Rotation Axes

RC servo motors have allowed the hobby robotics market to develop and flourish, but they were never designed for this application and have inherent issues, one of which is the fact that they only have one supported axis of rotation. Lynxmotion's Servo Erector Set (SES v1 system resolved this issue by creating brackets which added a rear, free spinning rotation axis.

The LSS motors not only include a rear axis, but two additional axes, allowing for external gearing and more. For example, a pair of spur gears can be mounted next to each other to create connected axes and an V-style gripper:

Accessories

The entire Servo Erector Set (SES) system might be considered "accessories" to the Lynxmotion smart servos. There are many types of brackets, channels, tubing and connectors.

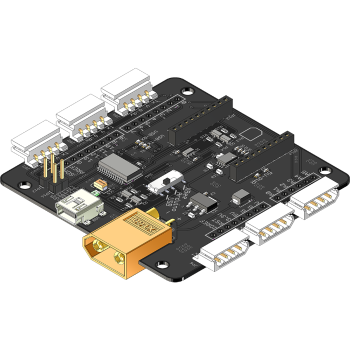

The Lynxmotion smart servos offer the greatest functionality when in serial mode, and the LSS Adapter was conceived to be one of the most versatile interfaces for these servos.

The board includes six LSS connectors, and an XT60 connector to power them. Aside from USB communication (computer, laptop or single board computer like a Rasbperry Pi), the board is Arduino shield compatible, has a Bee socket (XBee, Bluetooth Bee, WiFi Bee etc.) and can be connected to any serial port (microcontroller, FPGA etc.).

How do RC servos and Lynxmotion smart servos compare?

| Feature | Normal RC Servo | Continuous Rotation RC | Digital RC Servo | Lynxmotion Smart Servo |

| RC PWM Pulses | ✅ | ✅ | ✅ | ✅ |

| Serial / daisy chain | ❌ | ❌ | ❌ | ✅ |

| Intelligent Motion Control | ❌ | ❌ | ❌ | ✅ |

| Configurable Parameters | ❌ | ❌ | ✅ | ✅ |

| 360° Absolute positioning | ❌ | ❌ | ❌ | ✅ |

| Multi-turn virtual positioning | ❌ | ❌ | ❌ | ✅ |

| Wheel mode | ❌ | ✅ | ❌ | ✅ |

| Variable angular range | ❌ | ❌ | ✅ | ✅ |

| Sensor feedback | ❌ | ❌ | ❌ | ✅ |

| Built-in safety features | ❌ | ❌ | ❌ | ✅ |

What are they used for?

Fundamentally, a servo motor is designed to rotate to a desired angle against an opposing rotational load, or “torque”. RC (“remote control”) servo technology has been around for around for a while and allowed the RC industry (RC airplanes, cars, helicopters and boats) to exist and flourish. The LSS motors are primarily intended for the hobby robotics / animatronics markets, though when used as part of a normal RC system, they are some of the most versatile servos around. Hobby robots, which include robotic arms, humanoid and legged robots, among others benefit greatly from higher torque, advanced motion controller, sensor feedback and serial communication, which allows daisy chaining servos and eliminating the need for a dedicated RC servo controller.

Use case: Robotic arm

One of the most popular types of robots is understandably also one of the most practical: an articulated, mult-joint ("degree of freedom") robotic arm. Using the LSS actuators (instead of RC servos) in a hobby robot arm allows for:

Teach Mode

Position feedback can be used for a “teach mode” where the user physically places the arm in the position(s) where they want, and the software updates a virtual representation of the arm. Recording individual or multiple positions allows the user to create motion and sequences without having to do any programming.

Increased angular range and accuracy

Most normal RC servos can only rotate 180 degrees, whereas the LSS can rotate up to 360 degrees. The user can configure the maximum angular range which prevents the arm from hitting the brackets. The magnetic encoder allows for up to 0.1 degree of accuracy (depending on conditions), which means the positional accuracy of the end effector is very precise compared to most RC servos which use a mechanical rotary potentiometer to measure the angle.

Reduced complexity and increased versatility

The LSS motors were designed to be an integral part of any design with more connection points than almost any other smart servo motor on the market, where multiple brackets can be used simultaneously. The Lynxmotion Servo Erector Set (SES) v2 system has been re-conceived to allow increased functionality and optimized to work with the smart servos. The number of different hardware (screws and nuts) has decreased by almost 90% compared to the SES v1 system. A robot arm can be reconfigured within minutes using only one screwdriver to be longer or shorter, or add degrees of freedom.

Safety

Although the servo can be queried for temperature and current (and other parameters), the servo itself makes use of this information: if it encounters a situation in which the current spikes, is too high for a short period, or if the temperature reaches a specific value, it will shut down to protect itself. A normal RC servo would overheat and burn.

Three models

There are currently three versions of the Lynxmotion smart servos, which differ in maximum speed and torque (see the LSS - Specifications page on the Lynxmotion Wiki for details):

| Model | Speed (RPM) | Torque (Kg-cm) | |

| Standard (ST v1) | 60 | 14 | Learn more about the ST1 |

| High Speed (HS v1) | 100 | 8 | Learn more about the HS1 |

| High Torque (HT v1) | 60 | 29 | Learn more about the HT1 |

Using external gears like those which make up the 3:1 external gearbox kit (which can be used with any of the three servos) has the effect of decreasing the rpm while increasing the torque.

All three servos share the same firmware, which detects the model automatically and adjusts certain parameters to suit the model. Firmware updates are done through the LSS Configuration software, which also provides an interface for controlling a servo.

About Lynxmotion

Lynxmotion is one of the oldest brands of robot kits, including robot arms, biped walking robots, quadrupeds, hexapods, rovers and more. Lynxmotion platforms are well known in the robotics industry and are used by hobbyists, in education, by small and large businesses and also have been showcased in Hollywood movies and on television.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post