If you need to control a large motor but want it to have the same position control of a servo, you don't have to throw crazy amounts of money at it. You can actually have a plain old servo it self drive a large motor. This way you can feed the servo a desired position via a PWM signal, the servo tells the large motor which direction to move, and as the servo arm/pot is nudged back to equalibrium, the motor is brought to a stop.

So the first step is to take apart the servo, remove the second to last stage gear so the lever arm is free to spin yet still moves the POT. Next remove the motor, snipping the lead wires at the base of the motor. They will probably be mega short so maybe solder longer wire segments to them, drill tiny holes in the side of the servo to run these 2 wires out, then put the whole thing back to gether.

Ok, what do you do with these motor leads? The motor output of servos can NOT be directly attached to an H-bridge because the square wave output signals do not center at ground, they center at 2.5, so there is technically never an "off" moment (in the eyes of a transister). The servos do this because applying a mid voltage evenly to both sides of a motor prevents it from free spinning, this is also called, "Breaking". To use these signals in most motor driving applications, you could run both outputs through a comapator or schmit trigger to generate a new square wave that oscillates between 0 and 5.

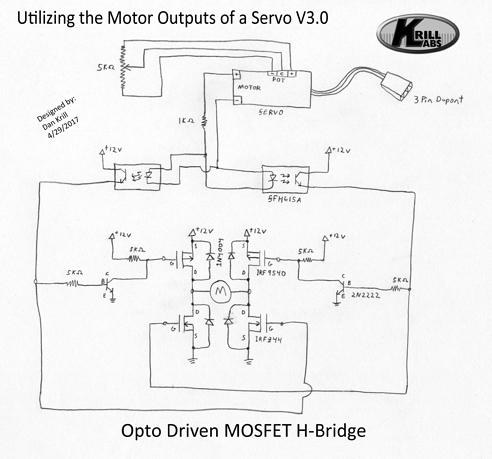

Now that your 2 control signals oscillate between the proper voltages you can attach it to anything, like an H-bridge. See the below diagram to see an example of attaching a mosfet based h-bridge to the comparitors for a fully functional externalized servo mechanism.

----- Updated 4-29-2017 --------

I have found that for the greatest efficiency and to reduce the chances of mosfet thermal overload, it is best to drive the h-bridge from corner to corner instead of from the same side. To do this requires a few extra components, but the results are even better! Why this is better is because there is no chance that the p-channel and n-channel mosfets on the same side could be on at the same time. On the same-side h-bridge, during an input voltage transition from 0 to 12, there is a brief moment when both fets are on at the same time causing a direct short, allowing too much current to pass, causing the fets to heat up faster. So this corner-to-corner h-bridge prevents that.

https://www.youtube.com/watch?v=usYpLUsRRNo?version=3