INTRODUCTION

It is a common picture in China, where I live, to see horribly maimed young children, which pitifully beg; especially at the tourist areas of big cities like Shanghai or Beijing. These children are most abducted from rural areas from poor parents by criminal gangs; the hands, arms or legs cut or broken, some have burnt skin. Their income is taken away; if too less, they are often beaten or unfed for days. I can't hardly change this situation by a robot entry, but what I can do is, to help poor children anywhere in the world, who have lost one or both hands by a physical handicap, accident, mutilation by criminals, anti-personnel mine or a piece of shrapnel in designing an affordable artificial hand - an artificial hand, controlled by electromyography, for no more than 10 Dollar.

How do now the plan to design an 10 Dollar artificial hand and the AFRON "10 Dollar Robot" Design Challenge fit in together? The goal of the AFRON Design Challenge is to design a new class of affordable robots for learning, mainly in primary and secondary schools. Well, the idea is, that the students building and programming the artificial hands and after the lessons are learned and the hands work properly, the hands are donated to maimed children, who can't afford a hand prosthesis. Therefore the hand has to be mass manufactured and supplied as a kit to the user.

The students will learn, how a robot end effector (gripper) and an Human Machine Interface (muscle sensor) works, they will discover the physics behind a robot end effector (for instance calculating the required gripping force) and train their craftsmanship by building the gripper. The students will furthermore learn how to solder the electronic components on the PCB, how a micro controller (Picaxe 08M2) works, how to write a program in Picaxe Basic and download the program to the micro controller.

THE GRIPPER

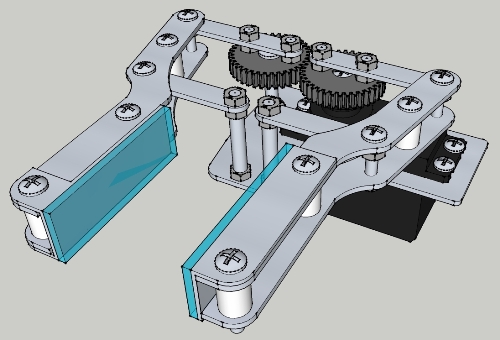

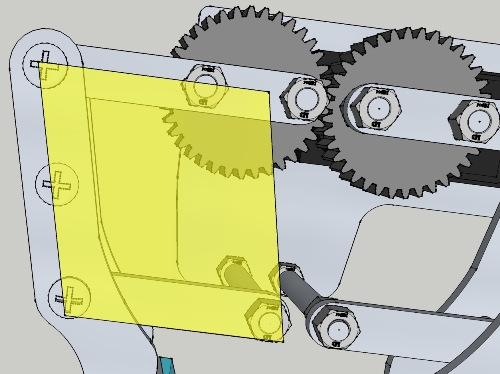

It is obviously, that a dexterous humanoid hand can't be built within such a small buget, so I decided to use a common gripper design with a parallelogram mechanism. The advantage of this kind of gripper is, that the gripping plates are always parallel to each other, which results in a better gripping. Such a gripper is also independent of the handedness, so it can replace a left or right hand equally.

The entirely gripper was designed with Google Sketchup. The main material is aluminium sheet with a thickness of 1.5 mm, beside some plastic standoffs, M3 screws and nuts, 2 mm silicone rubber pad to gain a high friction on the gripping plates and two plastic gears. The gripper is actuated by a cheap standard servo. The opening range of the gripper is 0-35 mm. A circular force sensing resistor (FSR) measures the jacking force during grasping, so even very fragile objects like glass or an egg can be grasped without destroying them. The maximal jacking force can be adjusted with a potentiometer on the control board.

Fig. 1 Gripper design

Fig. 2 Parallelogram mechanism

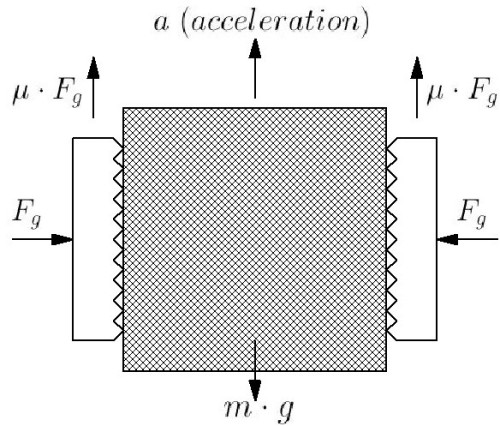

The gripping force, that must be applied, is given by

![]()

where

m = mass, kg

g = acceleration due to gravity, m/s²

Θ = angle subtended to horizontal

n = number of fingers

μ = coefficient of friction

This force represents only the static force. The static force is the minimum force that must be applied to the stationary object. When the object moves, it accelerates to some desired operation velocity. The worst case is, if it moves vertically upwards (see fig. 3).

Let's assume we want to lift up an object vertically with a mass of 500 g at an acceleration a of 10 m/s² to its desired velocity. The coefficient of friction between the gripping pads and the rectangular object (object is gripped in the middle) shall be 0.5. We get

![]()

To be absolutely sure of lifting the object, a safety factor should be included. Further reading: Robotics technology and flexible automation by S. R. Deb & Sankha Deb, 2010.

Grasps things, controlled by electrical activity produced by skeletal muscles

- Actuators / output devices: Gripper

- Control method: non-autonomous

- CPU: PICAXE 08M2

- Power source: 2 x 9V battery, 3 x 1.5V AA battery

- Programming language: Picaxe basic

- Sensors / input devices: 3 electrodes, FSR

- Target environment: indoors, Outdoors

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/the-artificial-hand-an-afron-10-dollar-robot-design-entry