This is my first robot. It's supposed to compete in the Penn State Abington Fire Fighter competion 2013 (missed the 2012).

Update:

The copper sides were a little too thin and the RC servos a little too hard to mount. Now I've got 3/4" (probably pine - from the Home Depot cull bin) and VEX 2-wire motors.

Anyone have a recommendation for a low cost but reasonably accurate quadrature encoder? I might just go with a pair of the VEX Optical Shaft Encoders but at $20 a pair (plus shipping) that's an expensive option. Since this is my first robot I don't have any idea what kind of resolution I'll need. I will have decent hardware support since the Cortex-M4 has built-in hardware based Quadrature Encoder Interfaces but so far as pulses per revolution go; all I know is the VEX encoders are 90 pulses per revolution with a max rate of 1700 pulses per second.

I've heard of using the encoders out of a mouse but the mechanics of getting everything put together, aligned, and reasonable light-tight might outweigh the cost of the VEX encoders.

Update on 4/18/2013

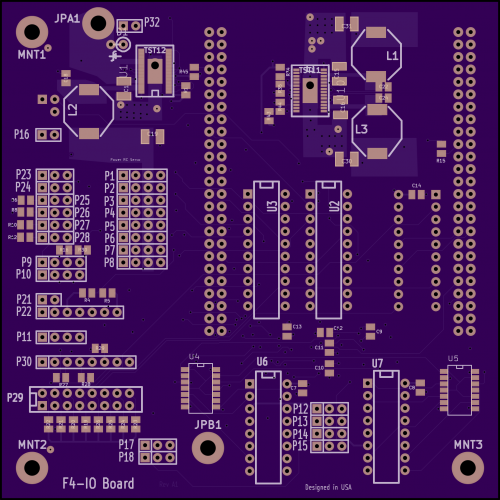

I finished the hardware on time for the Penn State 2013 Fire Fighting Robot competition but the software was no where near ready. The robot has an STM32F4Discovery board (with custom IO board) for controlling Pan and Tilt for the camera and fire extinguisher as well as full H-bridge drivers for the tank tread drive motors. I ended up using Vex quadrature encoders; for the cost it was worth avoiding the grief of building my own. Power is a 12V 5Ahr SLA battery. The black box on the right is the Wandboard Dual. It has a dual core Cortex-A9. It reads the camera input and tells the STM32F4 board what to do via an RS-232 link.

Here's some better images of the custom IO control board. PS -- I don't recommend hand soldering fine pitch SMT, it isn't easy but the three power supplies all work so it is possible...

Once I get some software written for it I hope to post some video.

Fire Fighter competition

- Actuators / output devices: Pan and Tilt control for fire extinguisher and camera

- Control method: Full autonomous

- CPU: STM32F4Discovery, Dual Cortex-A9 @ 1 GHz

- Operating system: RTEMS, Yocto embedded Linux

- Power source: 12V 5Ahr SLA

- Programming language: C

- Sensors / input devices: Webcam, sonar, accelerometer, Quadrature encoders

- Target environment: indoor competition

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/tankbot