Hello guys,

Sturdy is a sumo robot that is an upgrade to my previous sumo robot, Lambo-2WD.

Unlike scrapping and cutting our way through tin like last time, I thought of building a strong sumo-robot through standard mechanical approaches. (Drilling, Bending, Creating motor mounts, etc.).

Sturdy is armed with 6 motors - 3 on each side wired in parallel - that I found for a great deal on Ebay. The motors look very similar to the ones sold at Lynxmotion. The combination of torque and speed offered is incredible. This resulted with Sturdy being quite a competent fighter.

THE BUILD:

After a lot of navigation along the streets of Kathmandu, we found a nice factory that specialized in producing and manufacturing air-turbine ventilators. Although the people there were quite busy, they seemed to have liked the thought of building a body for a robot. It was a challenge for the both of us.

Here's how it all went:

THE BASE PLATE:

Having made several futile attempts at searching for an aluminum plate for the base of this robot, we were quite content with what we found at a local recycling store - a thick piece of metal covered in rust. Not bad considering the strength!

For high traction wheels, the ones on the internet were out of my budget. I decided to cast my own set of tyres using sealant silicone and while some results were pretty impressive like the one above...

....some were nasty and gooey.

Ordering six motor mounts from an online store seemed to be a bit less feasible considering the large number of motors used by Sturdy. Instead, we made our own clamps by chopping and drilling tin-sheets.

This particular machine in the factory easily allowed us to bend the motor mounts as per our requirements.

We indicated dots on the base plate for drilling the plate and then, clamping the motors. I wish we could have redone this part as the holes weren't entirely symmetrical. But they weren't way off either.

My camera has this gifted ability to blur out images at certain intervals. Perhaps, this picture was just another victim. (I could have taken another, but time!!!) Anyways, this is how the robot looked with the entire motors and wheels fixed onto the plate. Time to add the electronics.

The motors drew quite a lot of current and performed best at around 12 volts. A 3S Li-Po seemed perfect to power up Sturdy.

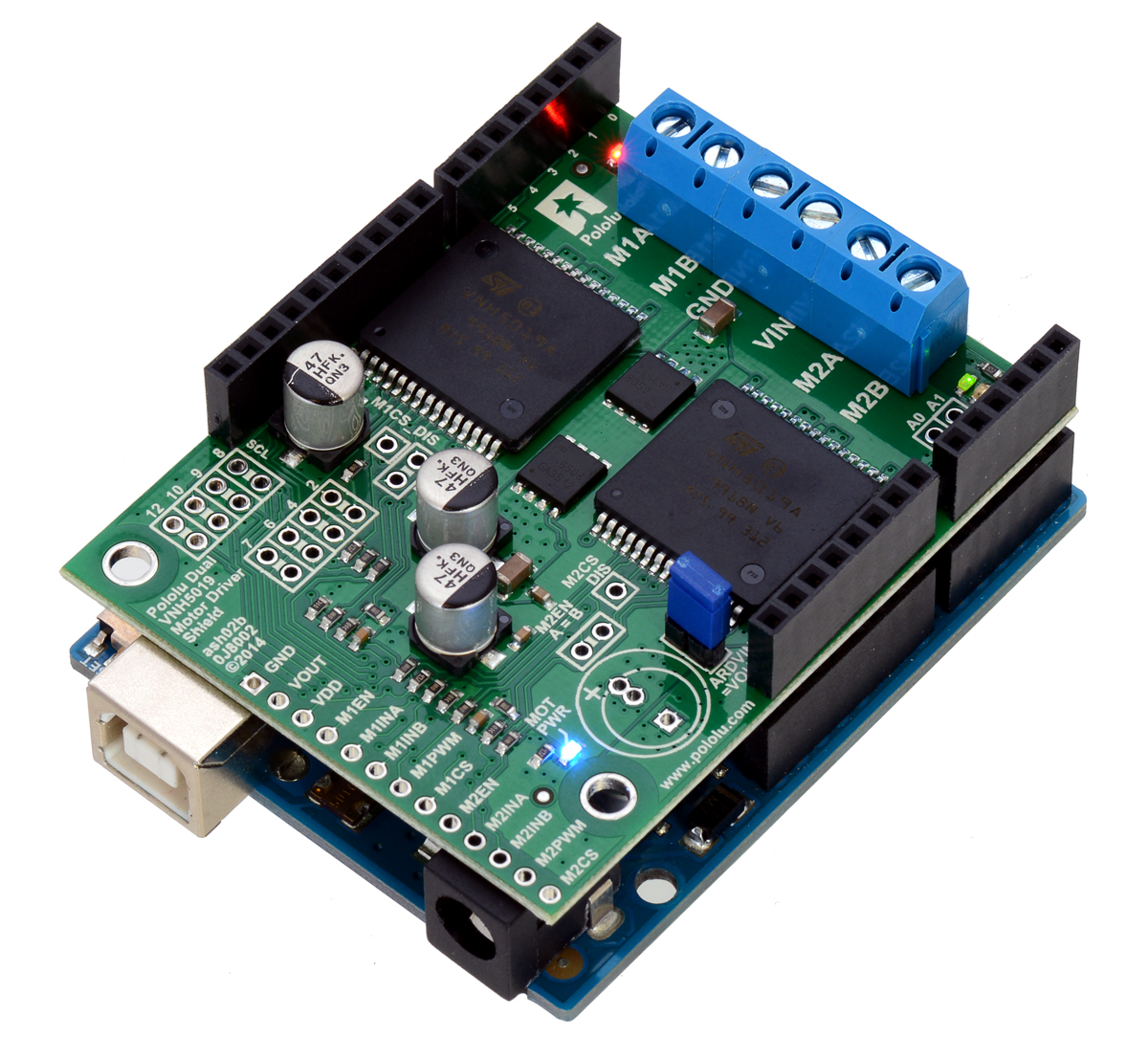

I had this powerful motor driver shield lying around from last year. It was a perfect time to test the Dual VNH5019 Motor Driver Shield from Pololu, to control the motors used in Sturdy.

We also designed a cover for the robot that could be screwed off for maintenance purposes. The wedge on the front also proved to be a strong weapon during battles.

And that was it. Sturdy was born!

Sturdy was designed to battle in the 3-kg Sumo Robot class. We kept that in mind while building it, but never did we thought it would be this close!

Hope you find the videos at the top interesting. One is a test video of Sturdy right after it got assembled. The other two are the performances of Sturdy at a national robot competition. Unfortuantely, due to time constraints, it wasn't possible to take more videos during the competition. Sturdy finished 4th in the event, but that was mostly due to a power issue that prevented the motors from spinning at full power. Anyways, it was fun building Sturdy. It'll get even more bad!

I'll try to add more pictures of Sturdy with the interiors and actual electronics assembly. Hopefully, there will also be a couple more videos of it in action.

Push other robots out of the ring

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/sturdy