stEve started life as a robot shaped sweetie tin. I received him as part of a Christmas present last year (2011) from some friends. This Christmas Eve stEve was born. I took the tin and opened some holes in the base for wheels. I had previously bought some geared stepper motors (28BYJ-48-5VDC) from ebay and though they didn't suit their original intended purpose they suited this bot down to a tee.

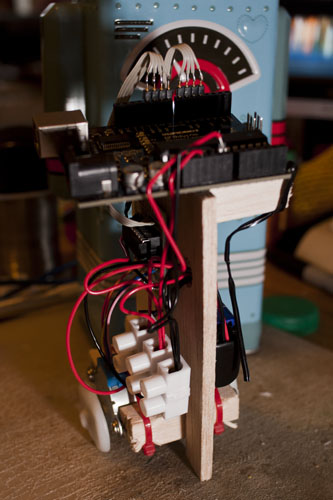

The two stepper motors drive ellipse shaped wheels made from shapelock/polymorph. When rotated to one position the wheel does not project below the bottom of the tin/base and stEve stands normally. Rotating one wheel through 180 degrees causes stEve to take a 'step' in an arc which pivots around the opposite edge of the tin/base. With 90 degree offset between the two wheels and both wheels spinning at the same constant speed stEve staggers forward.

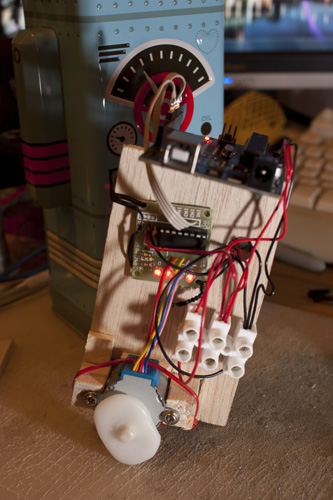

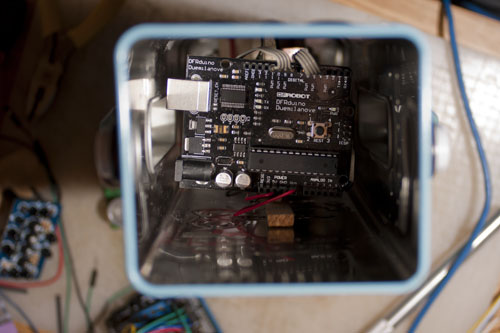

The steppers are currently driven by an Arduino (DFRobot.com Duemilanove) through their included ULN2003 driver boards, powered by the 5v regulated supply from the Arduino. A 9V battery feeds the Arduino though I'm not sure there is sufficient capacity for long duration use (something I'll need to investigate).

Everything is mounted on a removable sled made of balsa wood, with a thin piece of balsa wood jammed down the back to hold the sled in place. Superglue, zip/cable ties, twist ties and the occasional screw are all used to hold this together, a bit cludgy but I wasn't going for good looks as this is all hidden within a pretty robot shaped tin. I'm considering the addition of LDRs or LEDs to make stEve into a crude light chaser (phototropic robot) but for now he simply moves both his motors at a fixed pace. Further refinement of his wheels and possibly some way to determine their 'home' position may lead to more interesting walking methods.

A little update (18/01/13):

stEve still gets occasional attention from me, he's had his arduino and motor driver boards properly mounted with bolts now (previously held in place with twist-ties). I added a piezo speaker and merged my simple stepper motor control code with Auduino, which turns the arduino into a granular synthesizer. He plays random sounds between movements and tries to play Super Mario Bros theme tune when starting up (still needs a little tinkering, converted a midi file into a set of arrays for the arduino but it currently cannot handle overlapping notes (don't think I'll be able to make the arduino polyphonic, just one note at a time for now)). The piezo is not loud enough so I've ordered a 386N IC to build a simple amplifier and will include a small speaker within stEve's tin.

Recently I've been toying with the idea of printing replacement wheels, perhaps with the addition of some magnets which will trigger hall effect sensors to determine when the wheels are in the neutral position (horizontal, not touching the ground). I've also been seriously contemplating JerZ's idea of chopping stEve's head off and making it turn.

I like that I can safely stick stEve in my laptop bag and bring him with me to show off. Portability is definitely going to rank higher on my "important factors to consider" list with any future robot projects.

Walks (kind of)

- Actuators / output devices: 28BYJ-48-5VDC x 2

- Control method: none yet

- CPU: Arduino Duemilanove

- Power source: 9v PP3

- Sensors / input devices: none yet

- Target environment: Tabletop

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/steve