This is a bang bang (love that term) control machine with motors going full on in one direction or the other - no proportional control (though I have done that too now but my servo motors are just too slow (60rpm) to make nice with PID but I will post another video showing that too. Using only the single VTI SCA610 accelerometer chip as a simple tilt meter.

Version 2:

Still using orginal program which is essentially two if statements that turn both wheels on full speed in one direction or the other depending on which way it is leaning. Note that motors keep spinning in forward or reverse direction if you hold the pole down - just like a segway. You could carry a two day old kitten on this thing. Scale it up and ride it on the Bonneville salt flats - when you want to change direction just stop, get off, point it in the right direction and ride on.

a

a

Version 1:

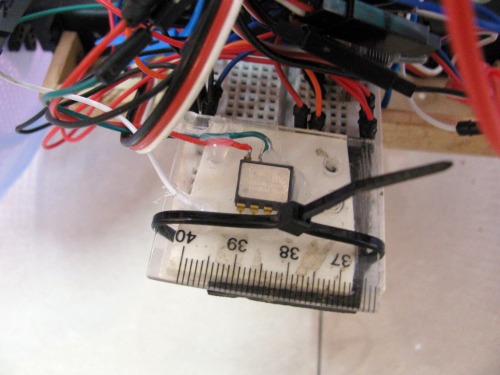

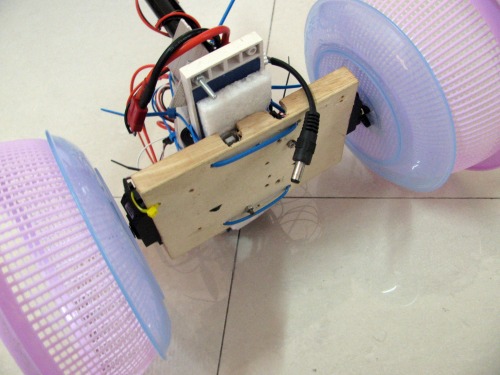

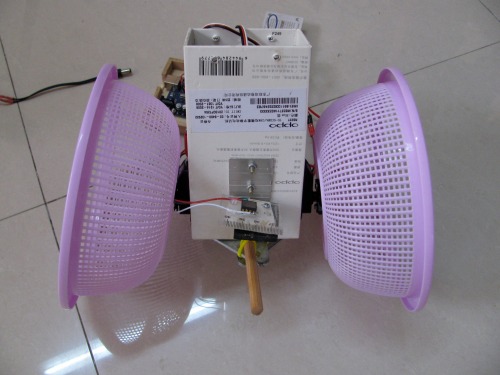

Made this little barely balancing robot using two continuous servos, plastic baskets for wheels, a VTI SCA610 accelerometer "inclinometer" chip. The arduino is just a couple of IF statements - no PID. Maybe thats my next step. Mostly I just wanted to test the chip for another project. Maybe I will mount the arduino on the robot chassis and try a little more seriously.

balances on two wheels - shakes like a Model A

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/self-balancing-robot-vers-2-bang-bang-control-no-proportional-mini-segway

It’s not the use of profesional gear it’s the idea what counts. Most of the times I am looking more to that simple projects coz they really make it work. It’s like the private space enterprises, much cheaper, less trouble with tousands of departments to sign up some documents, assign engineers etc… It’s just the pure pleaseure of making something.

It’s not the use of profesional gear it’s the idea what counts. Most of the times I am looking more to that simple projects coz they really make it work. It’s like the private space enterprises, much cheaper, less trouble with tousands of departments to sign up some documents, assign engineers etc… It’s just the pure pleaseure of making something.