What if you put your PET waste into the 3D printer instead of the recycling bag?

Is that possible?

Can we outline what is nessessary to build this machine? And why it is not available yet?

What if you put your PET waste into the 3D printer instead of the recycling bag?

Is that possible?

Can we outline what is nessessary to build this machine? And why it is not available yet?

My understanding is …

a reprap requires fairly consistent diameter. It would take a good deal of tech to get a consistent diameter of filament.

well, that is a difficult

well, that is a difficult task. first you have to chop and grind the plastic and then form a kind of filament. My idea would be a 2-step processing by grinding and melting the plastic in the first step and then pull/squeeze the filament out of the molten plastic. After cooling down it can be directly go to the extruder of the 3D printer to get heated again.

For a one-step processing it would need some kind of cylinder to squeeze the molten plastic directly from the pool into the nozzle. But to answer your question…YES it would be possible…there are no impossible things on LMR

what seemed like dreams in the past are reality today

Who knows, in the future this may indeed be possible. I would definately keep an open mind.

This is a wonderful idea! I

This is a wonderful idea! I love it so much I re-posted it on G+ to get more attention. We have to research how to make that filament out of chopped plastic. To chop the plastic we can use a coffee grinder but with a larger blade. Or a shredder type rollers. Then the plastic can go into a pressurized heating cylinder where it melts. Then we can push compressed air inside and open up a nozzle to get the filament and blow cool air on it to cool it down and spool it. Then it can be fed into the 3D printer. Hmm, it seems complicated, a lot of motors and moving parts, heating elements and cooling fans… A lot of electricity involved in the process. But to me, it’s worth researching and building such a machine.

Just found Filabot: Plastic

Just found Filabot: Plastic Filament Maker: http://www.kickstarter.com/projects/rocknail/filabot-plastic-filament-maker/

Seems like a good candidate for the machine!

Good find. You just gained

Good find. You just gained 17 internet points.

Thanks!

Thanks!

Perhaps we should add the

Perhaps we should add the Filabot on top of the MakiBox:

https://www.makible.com/projects/7-makibox-a6-the-300-desktop-3d-printer

I’ve been searching the net

I’ve been searching the net for the most affordable 3D printer. So far the cheapest is the MakiBox (not finished yet), then the Printrbot, then a DYI Prusa Mendel. I personally like the most the shape of the MakiBox. Not sure how fast or sturdy will be and how accurate will it print. If I’d have a 3D printer, I guess I’d design my own different one, taking ideas from each model I’ve seen and adding some of mine. I realy love the idea of integrating the plastic chopper/filament extruder into the machine. But why stop there?

See, I have this idea of a Star Trek Replicator machine, where you can place in a piece, it gets scanned, then you take it out and it gets replicated out of recyclable material. Perhaps it’ll take me a long time to do this (I don’t even have a 3D printer yet…), so I thought I’d share my idea for others to explore (or not). There are 3D laser scanners out there already, that use a webcam and a laser line scanned over the piece in a special setup. That can be integrated in the machine. But what about the computer? With the arrival of the Raspberry PI board we can integrate the computer too and use a touch display to interface with the machine. Or one of the new tablets with a 3D graphic processor. This way the user can browse the parts data base and see a rendering of the part on the screen, choose the size, material, etc. Or, the user can use a computer to draw a new part and transfer it to the machine through the wireless network, then have the machine print it. Think of a wireless 3D copier/printer machine. The possibilities are endless…

take this to the next level

You really take this to the next level, Gabriel. Thank you for your valuable contributions.

plastic is not plastic is not plastic

One challenge we face here is the toxic steam that comes from melting plastics. The steam that is generated by the melting process must be filtered when the machine is targeted to the consumer market.

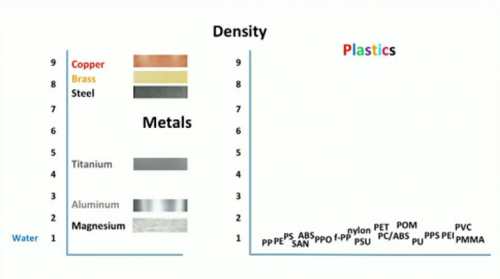

Further the high density of the plastic differences makes it very very hard to make shure you melt the right plastic. As we know plastic is not plastic is not plastic. Every plastic consists of different materials, flexibilizer and colors. When a machine is targeted for PET the machine must also have the ability to find out if the recycling material is PET. When the machine is targeted for any plastics it must provide strategies to distinct/differentiate the plastics and have melting temperatures and pressures for each plastic segment - you don’t want to burn the plastic.

Here a visualisation of the plastic density compared to “old” materials. It is obvious that “old” material can be differentiated a lot easier than plastics. Some metals have different colors. Some are magnetic. Some are more dense.

But with plastics that is finding a difference between C10H8O4 , C2H3Cl and C2H4 .

Image-Source: TED

Here is an example of 3D

Here is an example of 3D scanning: http://www.youtube.com/watch?v=w2uH1Ag2cAY

LOL just reading another

LOL just reading another thread and was checking out a link they had in it … and i came across this on the site … and i immediately thought of this thread.

http://www.kickstarter.com/projects/rocknail/filabot-plastic-filament-maker?ref=category

seems like there is a solution in the making .

3D Printed Furniture from Recycled e-Waste

"Dirk Vander Kooij, winner of the 2011 Dutch Design Award, has ingeniously reprogrammed an old industrial robot to extrude ground up and melted plastic from recycled electrical appliances like refrigerators, turning them into a tables and chairs. It’s just a surreal process to watch. Take a look at the video and see for yourself:"

http://www.3dprinter.net/dirk-vander-kooijs-3d-printed-furniture-from-e-waste