I performed an extensive (but not complete) set of tests yesterday. I confirmed some expected behaviors, and also found some surprises.

I tested on many, but not all of, the surfaces found in the [size=2][font=Arial]area[/font][/size] where the rover will wander: fabric, stained/varnished wood, varnished wood, painted (light color) wood, glass, stainless steel, hot rolled steel (blued, waxed). I took readings at distances of 30, 50, 80, 100, 200, 300 cm, at angles of incidence (aspects) of 90, 45, 20 degrees. For each test I took as many as 200 readings and did sort of a mental average.

I have to disclose that the measurements of distance and angle cannot be considered precise. As a result the accuracy of some readings are a but questionable.

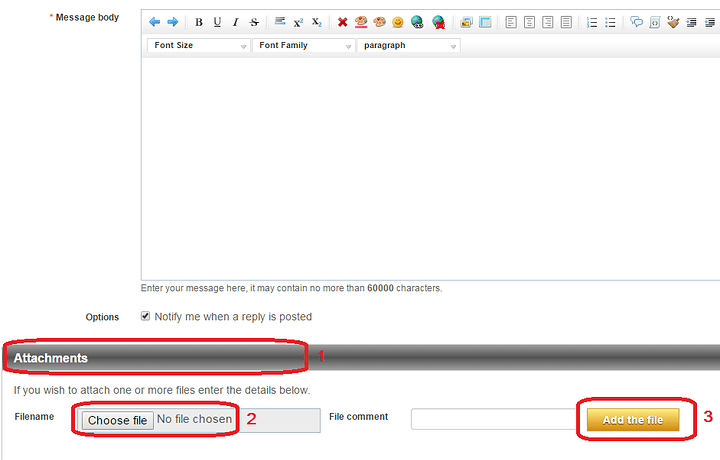

I’ll summarize the results here. I’d be happy to provide the details if I could figure out how to attach or upload images or a PDF.

][font=Arial][size=2]some combinations produced unstable readings; I categorized each combination as stable (where the individual readings varied by a few cm), unstable (where readings varied by as much as 10s of cm), very unstable (where readings varied by as much as 100s of cm); as an example the readings for stainless steel at [/size][/font][font=Arial][size=2]20° varied from 1 (presumably infinity) to over 300 cm[/size][/font]/:m]

][font=Arial][size=2]painted wood is the “best” surface and fabric the next “best” followed by any of the wood surfaces; glass and steel surfaces are bad news[/size][/font]/:m]

][size=2][font=Arial]90° readings are universally trustworthy (stable)[/font][/size]/:m]

][size=2][font=Arial]45° readings at distances >= 50 cm are trustworthy except for glass, steel, and stainless steel; the latter produce unstable or very unstable readings[/font][/size]/:m]

][size=2][font=Arial]20° readings between 50 and 200 cm are trustworthy except for glass, steel, and stainless steel; ditto[/font][/size]/:m]

][font=Arial][size=2]glass acts “opaque” at [/size][/font][font=Arial][size=2]90° but acts transparent at the other angles tested[/size][/font]/:m]

][font=Arial][size=2]for most surfaces, [/size][/font][font=Arial][size=2]20° readings @ 30 cm could not be obtained due to rover and room geometry [/size][/font]/:m]

These results have forced me to adjust my thinking about what I can achieve with the device. For the most part, it is not worth worrying about distances much below 50 cm. The non-linearity at and above 50 cm I’d seen in earlier tests is overwhelmed by other factors in my environment. As a consequence, I see no need (and as hypothesized by the manufacturer, no real ability) to construct a mapping that has any validity in my environment. I am also going to make sure that the glass is covered and so is not a factor, at least initially.

I am also going to have to adjust the expectations for using the device to create (and memorize) a map of the environment. Since angles much greater than [font=Arial][size=2]90° can be untrustworthy, I’ll have to move the rover more frequently and shorter distances so that I can achieve more readings taken at close to 90°. I think I should have expected this all along.[/size][/font]

[font=Arial][/font]

[font=Arial][size=2]I do have a couple of questions. Maybe RobotShop or the manufacturer can help:[/size][/font]

][font=Arial][size=2]as I said above, in some combinations, I got readings of 1 cm, clearly invalid; is 1 cm intended to mean infinity or error or something else?[/size][/font]/:m]

][font=Arial][size=2]the data sheet states a 680 microfarad capacitor should be used on the 5V supply; I’ve seen others use 1000 uf; I don’t have either of those values, so I used two 470 uf caps in parallel to give 940 uf; how close to 680 does the capacitance have to be? I’d really like to use only one 470 uf if possible [/size][/font]/:m]

][font=Arial][size=2]while I don’t anticipate buying the newer device for this project due to the rethinking above, I did do some searching, and it appears that the device is not yet available and in fact neither is a data sheet for it; when do you expect the device to become available?[/size][/font]/:m][font=Arial][size=2]

Thanks. [/size][/font]

[font=Arial][/font]

[font=Arial][/font]

) conditions, too. That being said, we are quite curious about what kind of results you can obtain. Indeed, non-linear does not imply not-consistent. This means you would need to determine all the variables that have an impact and account for them in your measurements.

) conditions, too. That being said, we are quite curious about what kind of results you can obtain. Indeed, non-linear does not imply not-consistent. This means you would need to determine all the variables that have an impact and account for them in your measurements.