Hi,

I am designing a canfield joint for a project and for that i need a programmable high precision servo motor with 1 degree of step angle rotation . I can’t find any related product so i shall be very thankful of someone can suggest any motor that fit this specification. the motor should not be very large sized (should be around maximum 50mm width) as i have already made the CAD file for the joint but it can also be changed accordingly to the motor. the higher the torque, the better as i don’t have any specific requirements yet. I shall be eagerly waiting for reply.

Thank you .

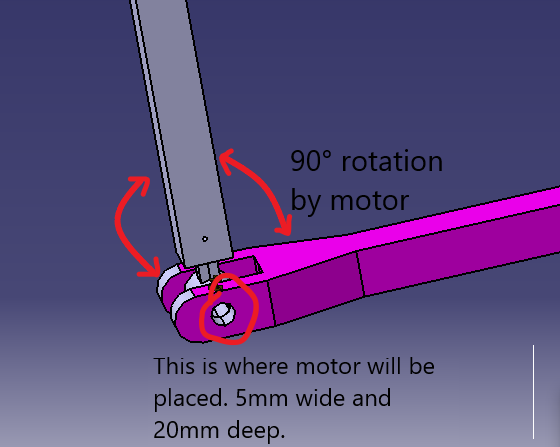

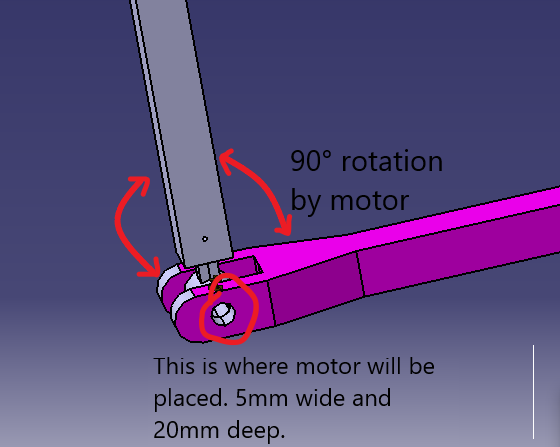

Edit: I have added the CAD picture to make better understand where the motor will get fitted.

Note: the dimensions of the model can be changed with respect to motor. I need three motors for three legs

Hey @safijatala!

Welcome to the RobotShop community!

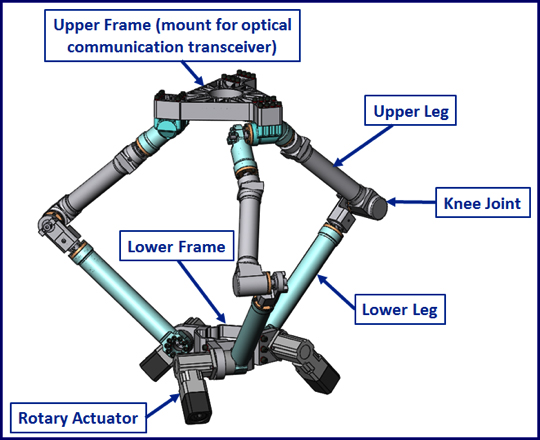

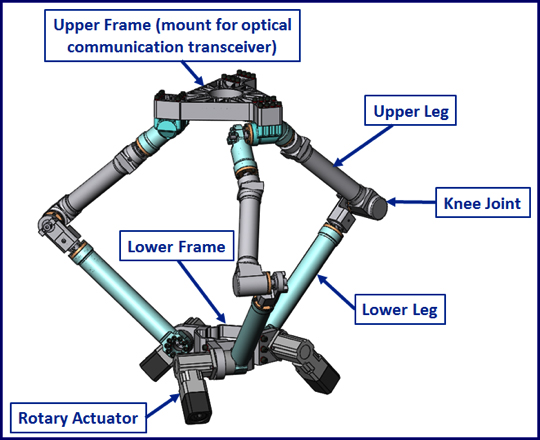

I assume something along this:

I’ve noticed you’ve mentioned many details about your Canfield joint such as motor size and resolution requirements… but nothing about torque. You most likely failure point in such a design would be using motor that cannot support the torque required or can support it but not for long enough (duty cycle) without damaging themselves / turning off.

Therefore, I strongly recommend that you provide a few more details, such as the length of each limb and the amount of torque required for each.

As a rule of thumb, you’d want the maximum torque of a joint to be at most 20-25% of the stall torque of the chosen motor. Said differently, once you’ve figured out the maximum torque (worse condition) of a joint, choose a motor with 4-5x the stall torque. This will allow you to have a system that can perform well. For better accuracy (and depending on the motor/gearbox/control used), you may even want to drop to 15% of the stall torque.

Good luck with your project!

Sincerely,

1 Like

Thank you for replying. I did not mention torque because it depends on the plastic material by which the model would be 3D printed. Each leg is 20 cm long with 1 cm width so at most the stall torque of motor should be 2-3 kg-cm. If you can suggest any motor model with these specifications that would be so kind of you.

Thank you.

1 Like

Since torque requirements are a primary characteristic for motor selection, this is pretty important. In cases where you are unsure of the final torque required, I recommend to simply use the worse case (at least for prototyping). That way you are certain it will work!

Sounds like a small enough amount that should be manageable with many different actuators we offer since 3 kg-cm x 5 = 15 kg-cm (note: assuming this torque requirement includes the weight of the motors in the assembly, if any). I usually add 10% on top of that just because actuators age, designs can change slightly, etc. so it is always good to have a bit more capacity than exactly what is needed.

In this case, I think something like the LSS might be a good fit for your use case. They have many mounting points directly on the servo case which makes them easy to integrate with most assemblies (and lots of brackets!). Also, they can be controlled by a simple serial protocol (there’s also Arduino & Python libraries) and provide a resolution of 0.1°. That being said, depending on load and use case (speed, assembly flex, motions types, advance settings) the accuracy is probably more around ±0.2-0.4° but 1.0° certainly sounds reasonably achievable in most cases.

For your case I’d recommend the LSS-HT1 [RB-Lyn-990] since it has ample torque capacity and a metal middle section for better cooling. It can run for a long time without heating up much.

Otherwise, you can find many other options of smart servos here.

Another alternative would be to use a geared stepper motor. These are very good at holding specific positions and if spec’d well torque-wise (so that you don’t ever skip steps) you can easily move any specific amount of discrete steps. The main problems with those are typically weight/size and current use though.

Good luck with your project! I recommend that you post about it here so you can get more visibility (and possibly help if needed) from the RobotShop community!

Sincerely,

1 Like

Thank you for the suggestion. I checked the model and it fits my requirements nicely but there is a negative point of being out of my budget, however i might go for ST1 as it also fits the torque and resolution requirements and is cheaper. I got a fair idea on what type of motors i should use and your recommendation helped me a lot so thanks again for your time. I’ll also post more on the link provided if needed.

Sincerely,

1 Like

Glad to hear! I’m happy this info was useful.

Yes, that is certainly true. Also, if the 60 RPM is not required you could always attach a gear reduction on the joints to sacrifice some speed for torque using this small gear [RB-Lyn-1011] and large gear [RB-Lyn-1014], providing a reduction of 1:3 (i.e.: by using those you would get 3x the torque but 1/3 the speed).

Sincerely,