Background:

In the future, it is undoubtedly that robots will replace human labor. Nowadays, the industrialization of robotic arms has become more mature, and more and more people are interested in robotic arms. Before getting to know about industrial robots, learning from educational robots is the most effective way. There are many robotic arms for education and science research, how do we choose in the robotics market?

Here we will provide two desktop six-axis robotic arms which are the preferred choices for individual developers who are new to robotics and want to create quick prototypes for personal or industrial use. And we will compare these two robots and help you find the best one for your needs.

First, Let’s introduce the differences between the industrial robotic arm and the collaborative robotic arm

Industrial robotic arm

As the name suggests, industrial robotic arms can replace humans working in factories, which can reduce production costs, improve productivity, and replace humans in dangerous positions.

Collaborative robotic arm

The collaborative robotic arm can interact directly with humans directly, which means that the collaborative robotic arm can work with humans together.Most industrial robotic arms are in centrosymmetric structure, and collaborative robotic arms are in UR structure.

We will start with the two robotic arms.

Introduction

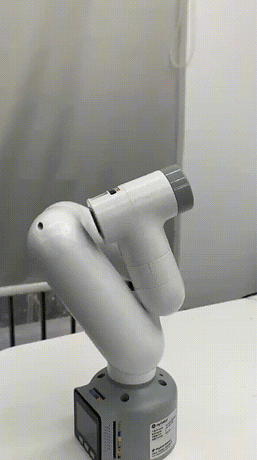

myCobot 280-M5Stack:

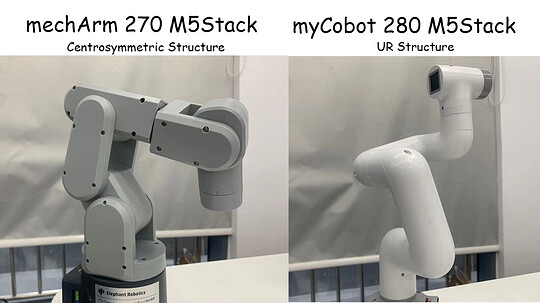

myCobot 280-M5Stack is a 6-axis collaborative robot powered by M5Stack-Basic with multiple functions, it is designed with UR structure.

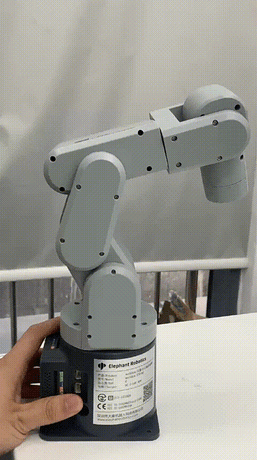

mechArM 270-M5Stack:

mechArm 270-M5Stack is similar to myCobot, but the structure of mechArm is centrosymmetric.

Development

The two robotic arms can do the same functions. myCobot and mechArm support users to quickly build a robotic arm programming environment and understand the arms control logic. It supports development in multiple languages such as Python, c++, c#, JavaScript, etc. Elephant Robotics provides a Gitbook for quickly building a robotic arm development environment with detailed tutorials on everything from setting up the environment to controlling the robotic arm.

ROS demo

Use the slider to control myCobot

MoveIt, Planning the movement of myCobot.

They can also work with AI(artificial intelligent) Kit to learn machine vision and robotic arm movements together.

The interfaces on the end of the robotic arm are the LEGO interfaces, we can use the accessories from Elephant Robotics or make by ourselves through 3D printing to complete our development needs.

Moreover, both of them support users to do secondary development, mainstream programming language development, and complete platform system development.

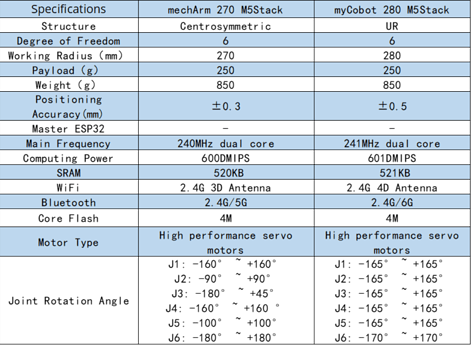

So what are the differences between them? Let’s look at their configuration.

The differences in working radius, positioning accuracy, and range of joint movements are due to their different structures.

Structure

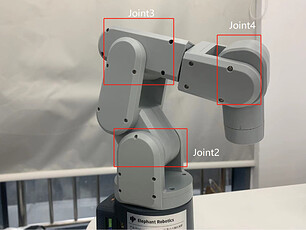

The centrosymmetric structure of mechArm is currently the most widely used and classic type worldwide.

The mechArm’s joint 2, 3, and 4 are all bilaterally supported, allowing for a more stable and smooth arm movement, which is why the centrosymmetric structure has been used again for decades.

The UR structured robotic arm joint works without holding, so it has a wider working radius and can move very flexibly. However, there are some deviations in the movement. Because without the holding, the robotic arm needs to rely on the motors to keep stable.

Joint rotation range

mechArm

myCobot

mechArm is limited in terms of movement, and myCobot is more flexible.

Summary

For mechArm 270-M5Stack

Advantages:

- The centrosymmetric structure keeps the robotic arm stable and smooth

- A comprehensive range of resources to get started quickly with the development

- It can be used as an introduction to industrial robotic arms to understand how they work

Disadvantage:

- The stability of movement is obtained, but the structure makes the joint rotation range relatively short.

For myCobot 280-M5Stack

Advantages:

- The UR structure makes the robot works more flexibly.

- It also has a comprehensive range of resources to enable a rapid development environment, and support multiple mainstream development platforms and programming languages

Disadvantages:

- There is a slight deviation in instability because of the structure. It is not as accurate as the mechArm. If we want to improve the position accuracy, we need to change to a better motor.

Both robotic arms represent the current mainstream types, each with advantages and disadvantages. We hope this article will help you choose a robotic arm that can meet your needs. If you still want to know more, feel free to comment below. If you like this article, please give us your support and praise. Your like is our motivation to update!