This is a secondary documentation page for my Senior Project for highschool, I'm building a cnc router with a budget of $700 bucks.

Basically, the plan is to build my router (codename Soundwave, like the decepticon transformer :P) and upon completion, use it to produce all of the circuitry, brackets and axis for a seconed router to donate to the technology department of my school. This project will take place over the course of this school year, and will be completed in Febuary (I hope).

I have more info here, on the projects actual webpage (that one will be graded)

PART ONE: MY MACHINE

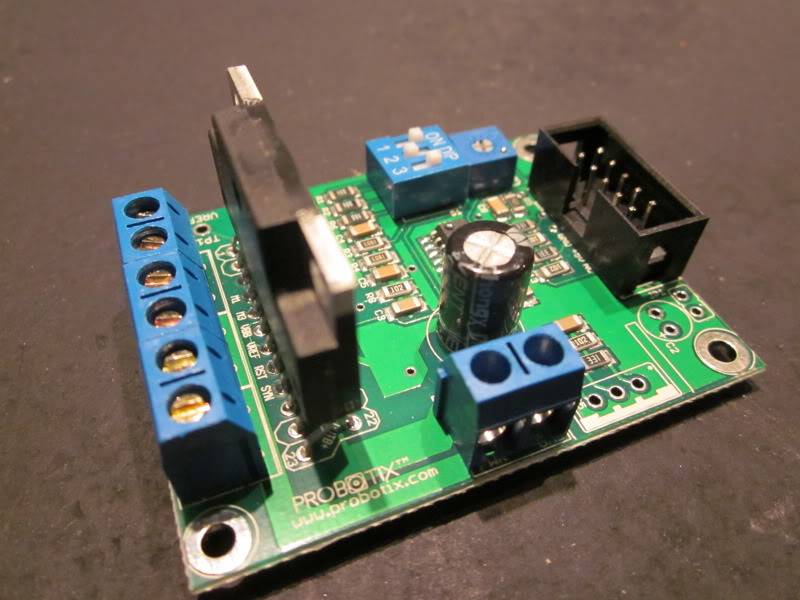

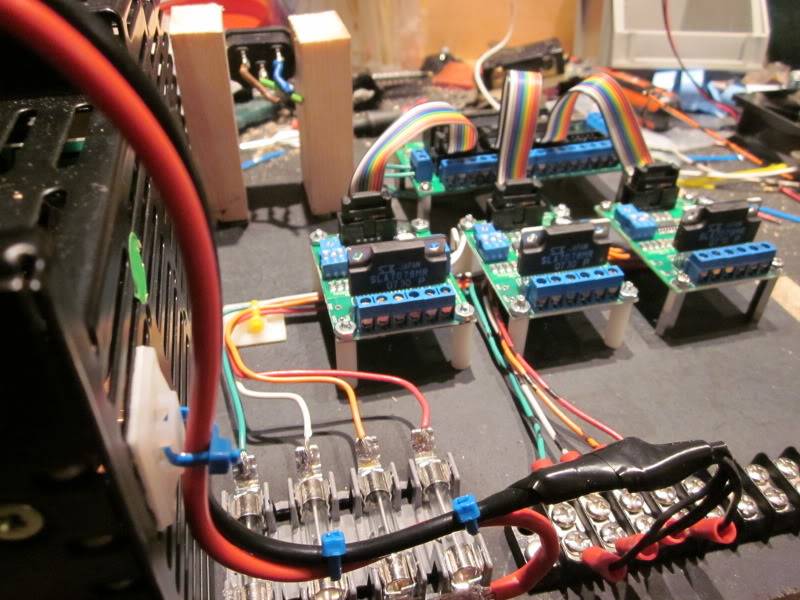

So far I have the control box built. I have 3 ProboStep Unipolar stepper motor drivers, a parallel port breakout board and a Wier HS100 24 volt PSU I had lying around.

Here you can see the finished heatsinking done with a 1/16" aluminum angle with fins cut into it.

More updates soon as mechanical components come in

UPDATE! 4/4/11

https://sites.google.com/a/webstercsd.org/lgary/

Its easier for me just to keep the updates here, All the mechanics should be finished up in a week or two, Ill keep this page updated!

This project has consumed my workshop!

I am also renaming it "Prowler", then I'm going to put a peacekeeper symbol on it, everything is better with sci-fi references!

PART TWO: THE SCHOOL MACHINE

For the motor drivers to be used on the seconed machine, I am between programming a PIC to interperate step and dir signals then driving the motor coild with MOSFETS or a L298 H-Bridge, or using a L297 and a L298 as a pair, the problem is that L297 chips are eight USD a piece. What do you guys think I should go with?

So I have finally settled on a design "train of thought" for the control for Machine part deux, behold the Xilinx XC9536 CLPD!!!! I was able to get ahold of a couple from my mentor for the project, (he literally had a case of these things)

Since I am much more comfortable designing at the gate level rather than verilog, or C/assembler with a MCU, CPLD's are a natural choice for me. I'm going to design and build an in circuit programmable CNC dedicated cpld dev board to create the step sequences for each motor, then break out those signals with some darlington transistors to drive the motors. I figure this will be a pretty simple and easily updatable design, should be pretty fun too!

A far as the mechanics, It will be similar to the "Mantis" if anyone has ever seen it.

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/my-cnc-senior-project