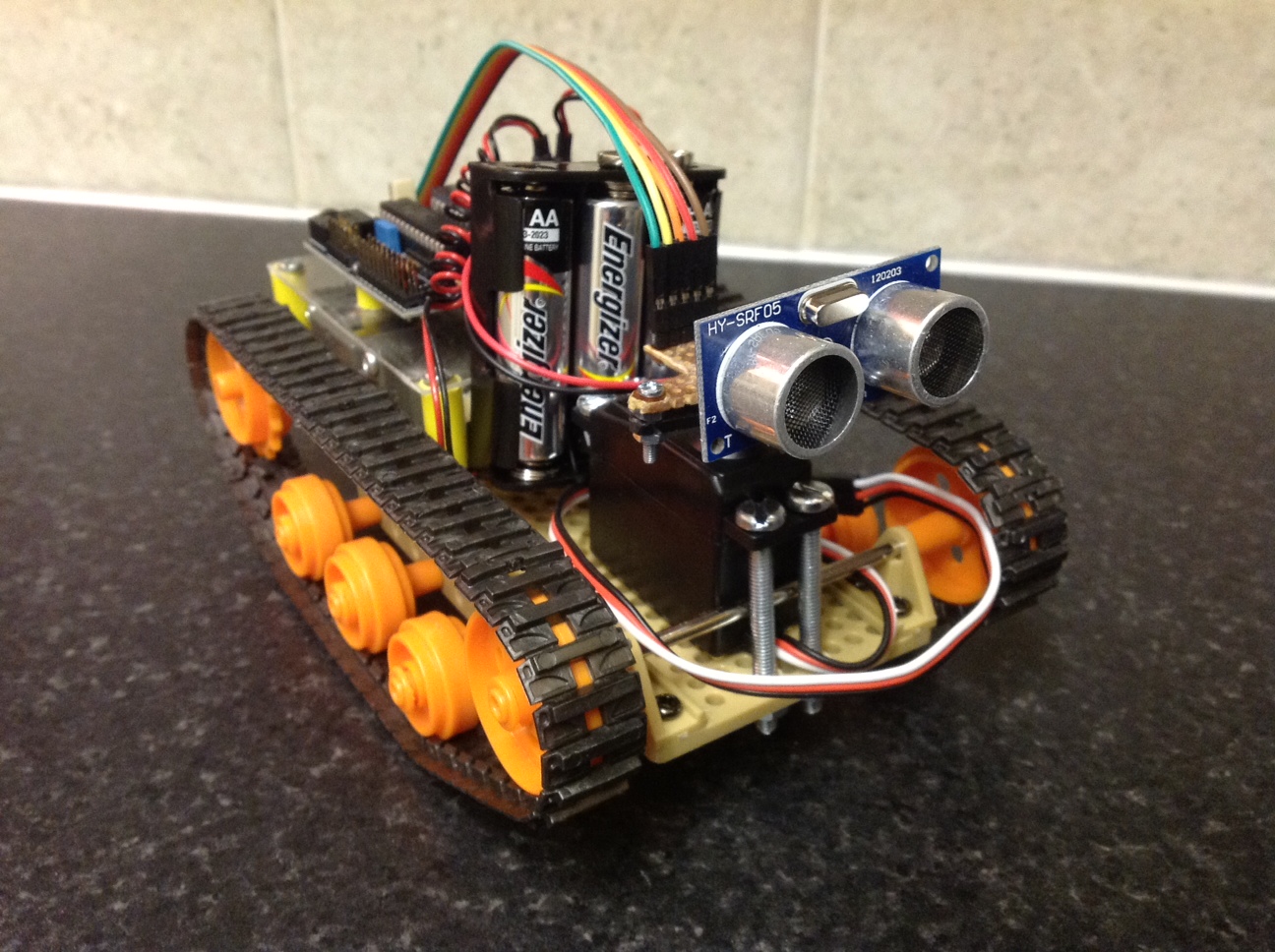

Ok. I have started my first custom robot! I'm going to call him "Luigi" cuz he was going to be controlled by an Arduino, but I decided not to. But its a cool name!

You're probably disappointed because I'm using pre-built VEX pieces. That's okay, because I'm going to change that to PICAXE soon enough. I just can't wait till I get my parts! I want to build a robot NOW!

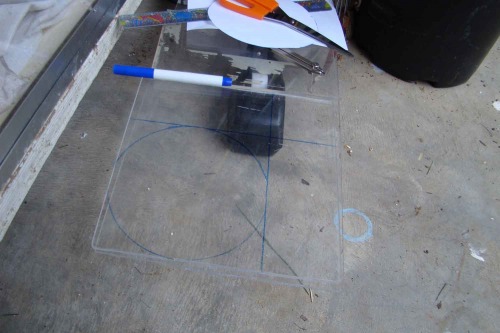

I am in the works of cutting my sheet of plastic (yes, by hand, not with Dremels or machining tools or lasers.) I got a major cramp in my wrist. ☺

See?

That's my cut-out piece of plastic. After a while, I realized that it was too big. Time to draw up a new design...

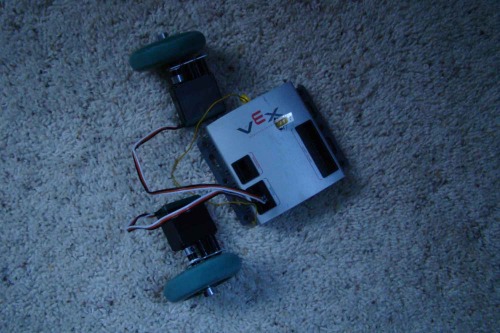

Those are the VEX parts I will use in the initial model of the robot. It's radio- controlled, but I could program it if I bought this expensive programmer thing. But it probably has plenty of power, as its run off of two sizeable surface mount PICs.

Ok, now I'm getting lazy.

There's a rotary tool with a cutting attachment being glued on.

Then I tried it. The tool melted the plastic, so I'm probably not going to use it anymore.

Keep waiting for more updates everybody!

UPDATE:

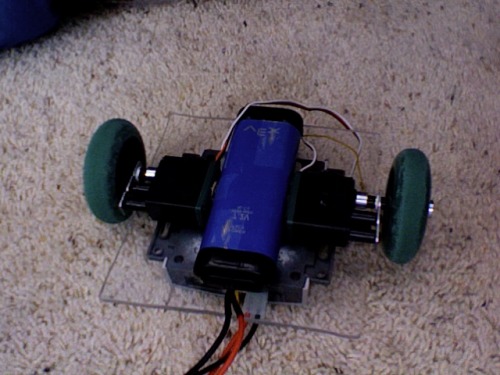

I finished the prototype. Basically, I stuck some Vex motors onto the plastic. With LiquidNails. Bad, lazy, me! Well, it looks good, even if my crappy webcam pics don't show it! But then I left my robot sitting there and the glue (which apparently never dries properly) kinda let go of the motors. SOOOOOO....... we can determine that we should never use Liquidnails in any other application than wood.

yup, that's an iSight picture alright

that's the bottom. See the big, heavy battery class? That's 2000mAH of 7.2 volt juice! (believe me, I have no idea what i'm talking about, I just read that off the battery. I need some classes on what is current!)

Ok. So forget that.

Good news! I finally put in that order! I'm gonna get real parts! And its gonna cost 160 bucks! Yeehaw!

For those of you who care to wonder what I ordered from HVW Technologies, here's a list.

Picaxe 28x1 starter pack

L293D motor driver, x2

GM9 Track Set

GM Wheels, x2

AIRRS, Sharp

Servo S03N

GM Brackets x2

Super Bright LED Blue

Servo Wire x5 (for connecting sensors)

1/2" Plastic Ball caster, x2

Picaxe 28x1 IC, just in case I burn out the other one! I'm taking no chances after the BS2... Also, is there a post somewhere that shows you how to make your own board?

Should be showing up in a week or so.

Obey my every wish

- Control method: Radio controlled, but soon to be autonomous

- CPU: VEX microprocessor

- Power source: 7.2 volts, 2000mAh

- Programming language: C

- Sensors / input devices: ...ummm, nothing yet

- Target environment: indoor, maybe outdoor

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/luigi