Just ran across this forum and have come to the conclusion I may not be as odd as my neighbor’s think I am. There are actually other people building robot rovers in their garage!

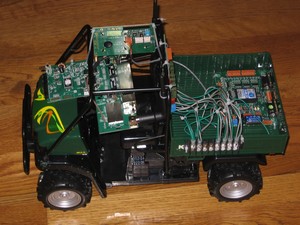

I started by building an internet controlled RC car. I thought the internet controls would be dificult and I did not want to invest in an expensive vehicle until I had confidence in building the controls. Turned out much easier than I thought. I simply bridged a Linksys router, on the car, to the Linksys router in my house. The RC car was way too fast for the internet connection though. After crashing the $20 car with $300 worth of controls on it, I decided it was time for a new vehicle.

My next project was a kids car. Moving the controls from the RC over to the Kids car was a snap. Since the car was much bigger, I added two air soft uzis and an Internet camera. What a hoot! The kids love it. The two uzis empty in about 15 seconds and spray a wide path. It’s hard to miss

But the kids car isn’t powerful enough to climb hills and gets stuck on wet grass and small stones. The darn thing only has one tiny drive motor attached to one rear wheel. I bought it new on ebay for a $100. But you get what you pay for.

I’m now building my own vehicle. I bought 4 16" lawn tractor tires at Northern Tool and Supply last weekend, sprockets from McMaster Car and a Lessen 360 in-lb, 5 RPM motor. That’s right, 5 RPM. I’m aiming for 20’ per minute because of the delays in the video picture and controls over the internet. I intend to add a second identical motor and use skid steering. I’ll be testing the power of the one motor and 16" wheels this weekend. Though simple calculations tell me I should get 45 lbs of push with the one motor.

Finally, my question: Does anyone have any experience with “Skid Steering”? Do you think two 360 in-lb motors will be able to do it with 16" diameter tractor wheels? Will the span between the wheels make much difference? I’ll be driving the left two wheels with one motor and the right two with another.

I’ll post some photos and a link to my project page if the forum allows me to tomorrow.

Cambot

A character, yes, though.

A character, yes, though.

All I would really want is one to be a roving access point and wireless link for a robot. If a V5 router will handle that with the DD-WRT or similar firmware, then I think it would work fine for me.

All I would really want is one to be a roving access point and wireless link for a robot. If a V5 router will handle that with the DD-WRT or similar firmware, then I think it would work fine for me.