sorry about the slow reply

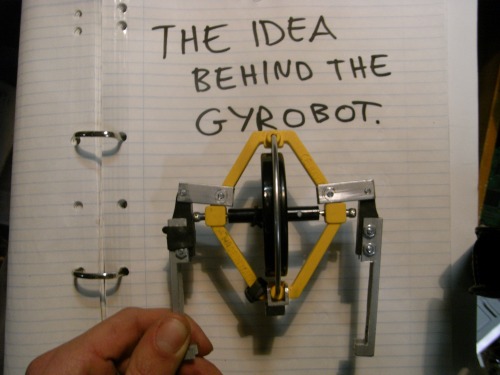

Thanks for the input, I really appreciate it. My experiance of gyros is just from observation, I’ll outline the idea development:

I first started playing with a bike wheel & having it spinning between my hands in the same orientation as in the robot photo.

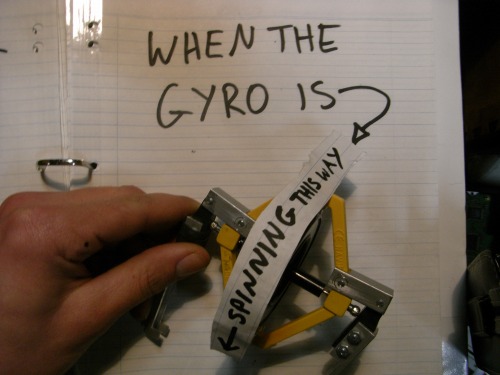

I noticed if I dropped one hand, the wheel supported itself and rotated on the other hand.

Based on this I intended to make the robot as the one above but with retracting pistons for legs.

ie: lift leg, bot rotates say 80 degrees or so forward, lower leg and lift the other & the same happens in opposite rotational direction.

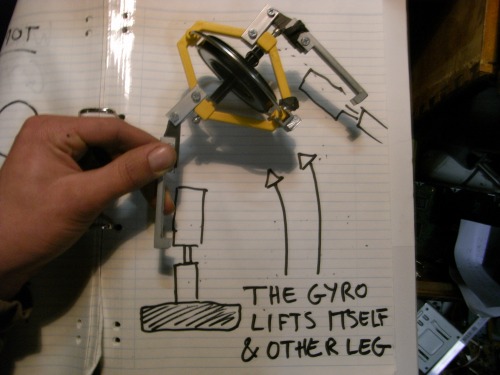

I then made up the frame work and discovered that the weight of the extras (legs and pivots) meant that when the leg was retracted the gyro dropped very rapidly and had very minimal rotation - micro steps

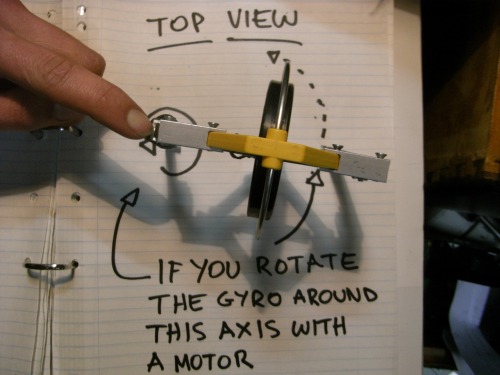

I then saw that quickly twisting one leg threw the gyro and other up in the air, even with the added weight.

Then I encountered the problem of the foot slipping and the other failings.

I think you are correct in surmising that the present arrangement will result in a shuffle.

Further consideration of the physics makes me think that a combination of lifting and twisting is needed if it is to work. Or maybe better still the foot that twists may extend forcing it to grip the ground more.

I agree with the ideas of making the mass around the gyro wheel greater and a bigger diameter wheel whould improve its capabilities.(and lighter motors)

Although I have seen that the speed of the gyro certainly appears to be proportionally related to the force required to tilt off its spinning axis. This makes sense to me then, that the faster it spins (to a degree) the more weight I can hang off the pivot and have the gyro carry the weight forward.

) of making it quite large, 2+ meters. I wanted it to walk around the yard.

) of making it quite large, 2+ meters. I wanted it to walk around the yard.