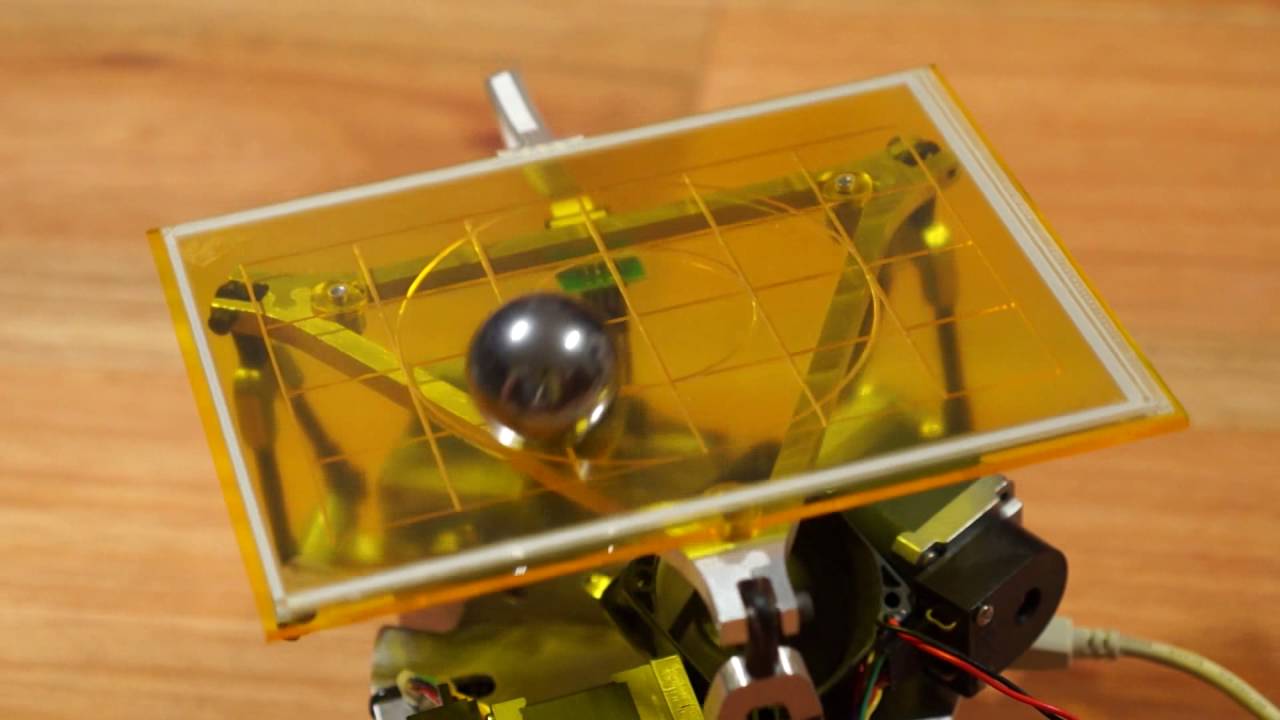

Hi, I’m new to the world of robotics. I would need to build a leveling surface, something like this:

That can support and move an object placed on it that weighs approximately 15kg.

From an electronic point of view I don’t have many problems, I’m quite an expert in electronics and I know exactly what to do. My problem is in the mechanics. While it doesn’t look particularly complex, there are lots of little bits and pieces, rods, bolts, screws, …

All things that I have no idea where you can buy them and how to choose them. I tried looking around the internet, but it’s more complex than it seems.

Can anyone help me choose the components I need and maybe even know where to buy them at a good price.

Or (which would be the ideal solution) can you tell me if something like this already exists, already made and which can support the weight I need?

Thanks in advance.

1 Like

Hi @FedericoMassimi and welcome to our forum.

This is a very interesting project, but you would need a lot of work if you need complete mechanics.

Do you already know which servo motors you would use?

Based on your drawings, you would need a couple of servos (although these look like stepper motors on the photo), two mounting plates, connecting rods, and some additional parts to connect these all together.

My guess is that some mechanical designer used 3D CAD software (like Solidworks, Inventor, etc.) to design these metal parts and make them on CNC machine. This should not be very hard, but I guess you need to start from something. I would recommend that you start from the motors.

Hi @FedericoMassimi ,

It looks like a good motor.

The unit should be 25 kg.cm. You can see it is mentioned in the product specification.

For rod end, here are some examples:

You need to find some rods also.

These parts can be found online, but sometimes it is important to get correct naming.

OK, thanks a lot.

One last question, searching on YouTube, I have seen various systems of this kind, and I noticed that some use servomotors (such as those for modeling controlled in PWM) while others use stepper motors.

For example these have steppers:

and these have servomotors:

My impression is that stepper motors have “softer” movements, are smoother and less noisy; while PWM servo motors are jerkier and noisier.

Is this impression of mine true? does it derive only from mechanical construction? or is it an intrinsic characteristic of the two types of motors?

1 Like

The difference that you noticed could be coming from this particular use case. Meaning, maybe the servo motors in this project are not suitable one, or they are not programmed correctly or something else. In principal, servo motors should be better comparing to stepper, but more expensive.

Here are some comparisons: