Here an example of position control of a Brushless DC or Permanent Magnet Synchronous Motor.

The goal will be to have a infinite loop with:

- A spin of the motor from 0 to +50000 pulses with 5000 RPM plus a short wait time

- Turning back the Motor into -32559 pulses with 1500 RPM of speed plus a short wait time

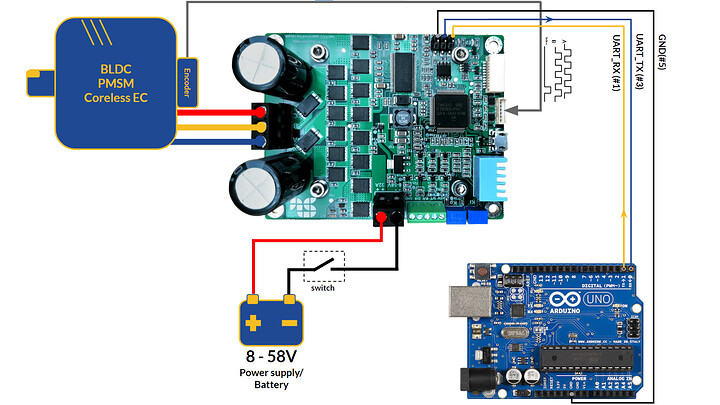

For this example I’m using:

- Arduino Uno

- Brushless Motor as teknic m-2310P-LN-04K This Motor has 8 Poles with an internal Encoder with 1000 physical lines pre-quad, meaning that in 1 turn rotation the motor controller will read 4000 pulses generated by this motor’s encoder in quadrature manner ( 4 times more)

- Solo Uno as motor controller used as servo drive.

To make it work, I also use the Library for communication between Arduino and Solo, more info here.

The schematic:

- The piano switch for Solo Uno is from pin 1 to 5: Up, Up, Up, Up, Down.

- Correctly calibrated the Encoder with correct connection of the Motor’s windings to ABC outputs of Solo Uno

The code:

#include <SOLOMotorController.h>

//instanciate a SOLO object:

SOLOMotorController *SOLO_Obj1;

//the device address of SOLO:

unsigned char SOLO_address1=0;

//Desired Switching or PWM Frequency at Output

long pwmFrequency=70;

//Motor's Number of Poles

long numberOfPoles = 8;

//Motor's Number of Encoder Lines (PPR pre-quad)

long numberOfEncoderLines = 1000;

//Select the Normal BLDC_PMSM motor type

long motorType= 1;

//Speed controller Kp

float speedControllerKp = 0.15;

//Speed controller Ki

float speedControllerKi = 0.03;

//Position controller Kp

float positionControllerKp = 0.12;

//Position controller Ki

float positionControllerKi = 0.02;

// Current Limit of the Motor

float currentLimit= 15.0;

// Battery or Bus Voltage

float busVoltage = 0;

// Desired Speed Limit[RPM]

long desiredSpeedLimit =3000;

// Desired Position Reference

long desiredPositionReference =0;

// Motor speed feedback

long actualMotorSpeed = 0;

// Motor position feedback

long actualMotorPosition = 0;

void setup() {

//In this example, make sure you put SOLO into Closed-Loop by

// pressing the Piano Switch NO# 5 DOWN. in SOLO UNO

//High Speed High Performance Baudrate (Recommended)

//Use this baudrate to have the best and real performance

//of SOLO under all conditions.

//Serial.begin(937500);

//Low Speed Low Performance Baudrate

//Use this baudrate only for devices that don't support

//937500 or 921600 baudrates.

Serial.begin(115200);

//Initialize the SOLO object

SOLO_Obj1 = new SOLOMotorController(SOLO_address1);

delay(2000);

busVoltage = SOLO_Obj1->GetBusVoltage();

while(busVoltage <=0){

busVoltage = SOLO_Obj1->GetBusVoltage();

//wait here till communication is established

Serial.println("\n Trying to Connect To SOLO");

delay(1000);

}

Serial.println("\n Communication Established succuessfully!");

//dummy read after Serial.println to open the UART line

SOLO_Obj1->GetBusVoltage();

// Initial Configurations

SOLO_Obj1->SetPWMFrequency(pwmFrequency);

SOLO_Obj1->SetCurrentLimit(currentLimit);

SOLO_Obj1->SetEncoderLines(numberOfEncoderLines);

//select Digital Mode

SOLO_Obj1->SetCommandMode(1);

SOLO_Obj1->SetMotorType(motorType);

//run the motor identification

//run ID. always after selecting the Motor Type!

SOLO_Obj1->SetIdentification(1);

Serial.println("\n Identifying the Motor");

//wait at least for 2sec till ID. is done

delay(2000);

//dummy read after Serial.println to open the UART line

SOLO_Obj1->GetBusVoltage();

//Operate while using Quadrature Encoder

SOLO_Obj1->SetSpeedControlMode(1);

//Control The Position

SOLO_Obj1->SetControlMode(2);

//Speed Controller Tunings

SOLO_Obj1->SetSpeedControllerKp(speedControllerKp);

SOLO_Obj1->SetSpeedControllerKi(speedControllerKi);

//Position Controller Tunings

SOLO_Obj1->SetPositionControllerKp(positionControllerKp);

SOLO_Obj1->SetPositionControllerKi(positionControllerKi);

}

void loop() {

//set a desired Speed Limit for trajectory in RPM

desiredSpeedLimit = 5000;

SOLO_Obj1->SetSpeedLimit(desiredSpeedLimit);

// set a positive desired Position Reference

desiredPositionReference =+500000;

SOLO_Obj1->SetDesiredPosition(desiredPositionReference);

// wait till motor reaches to the reference

delay(3000);

actualMotorPosition = SOLO_Obj1->GetEncoderPosition();

Serial.println("\n Number of Pulses passed: ");

Serial.println(actualMotorPosition);

//dummy read after Serial.println to open the UART line

SOLO_Obj1->GetBusVoltage();

//set a desired Speed Limit for trajectory in RPM

desiredSpeedLimit = 1500;

SOLO_Obj1->SetSpeedLimit(desiredSpeedLimit);

// set a negative desired Position Reference

desiredPositionReference =-32559;

SOLO_Obj1->SetDesiredPosition(desiredPositionReference);

// wait till motor reaches to the reference

delay(6000);

actualMotorPosition = SOLO_Obj1->GetEncoderPosition();

Serial.println("\n Number of Pulses passed: ");

Serial.println(actualMotorPosition);

//dummy read after Serial.println to open the UART line

SOLO_Obj1->GetBusVoltage();

}

So, after setting up the essential parameters like the Motor’s number or Poles, Encoder lines and others, in the loop the main code of this example.

It worth mentioning that when Solo Uno is in Position Mode, it counts the pulses in a quadrature manner, so the feedbacks and the references are all in quadrature form, for instance in this example when we ask SOLO to traverse the shaft of the motor into +50000 pulses, if we consider the initial starting point is at zero, we are spinning the motor for (+50000 / ( 10000 * 4)) = 12.5 turns or 4500.0 degrees, so it is possible to calculate the exact end point and provide desired reference to Solo Uno to reach a different goal.