July 7, 2013

I started to build the first prototype of Cosma. Cosma is basically a robot astronaut. The primary goal of this robot project is to send a small humanoid robot into Space using the eXSShot rocket. This first version will be send to near Space via a weather balloon --- maybe end of this year.

The main idea is that not the raw data of the robots sensor devices are send back to Earth; the data are rather processed into human impressions and the according generated expressions then transmitted. So the ground station doesn't receive pitch, roll, acceleration, temperature or image data from the robot, but rather spoken statements just like a real astronaut would be sitting in the rocket capsule and commenting the surrounding scene. Additonally the raw data and the spoken statements are stored on a micro SD card.

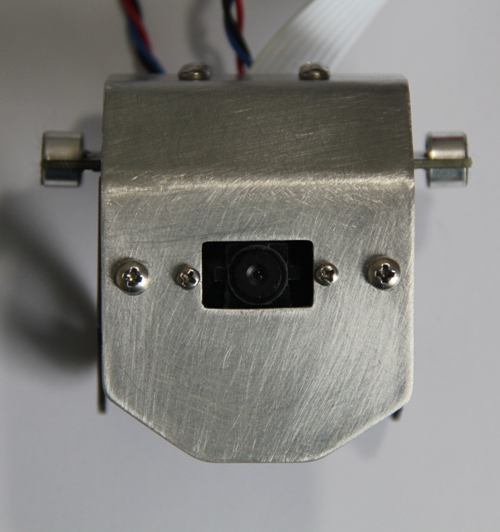

Fig. 1 Front view of the head. The eye of the robot is a Stoneyman camera , the ears 2 dfrobot analog sound sensors

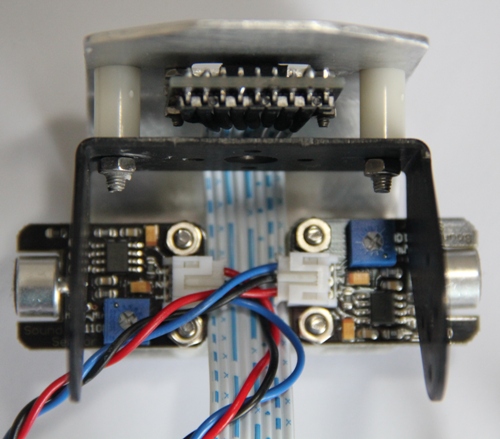

Fig. 2 Side view of the head

Fig. 3 Back view of the head

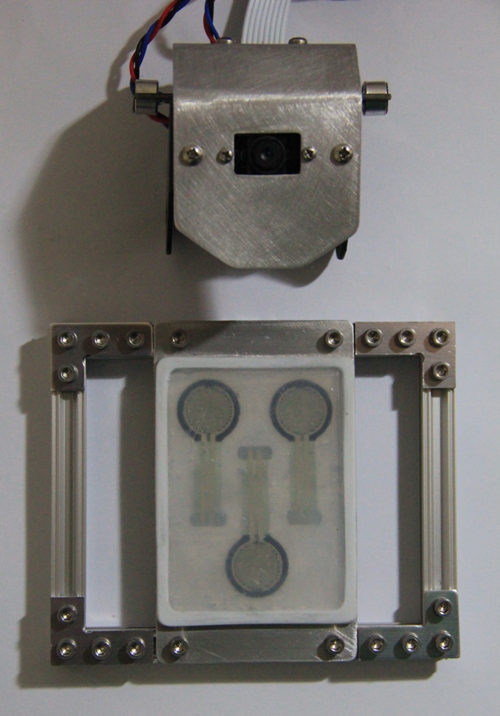

Fig. 4 Solar plexus of the robot under construction. The pain receptors are FSRs (Force Sensing Resistors)

Fig. 5 Robot skin (Silicone sealant) applied. Same trapped air bubbles because of lack of a vacuum chamber

July 9, 2013

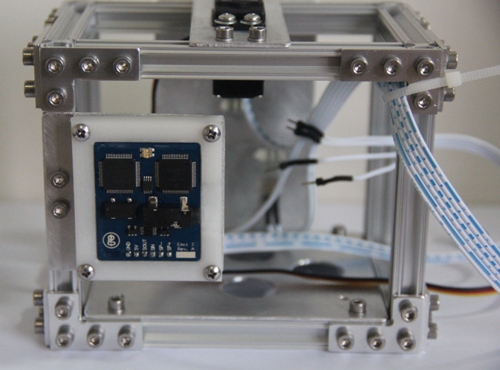

Main frame of the robot under construction, using MicroRax:

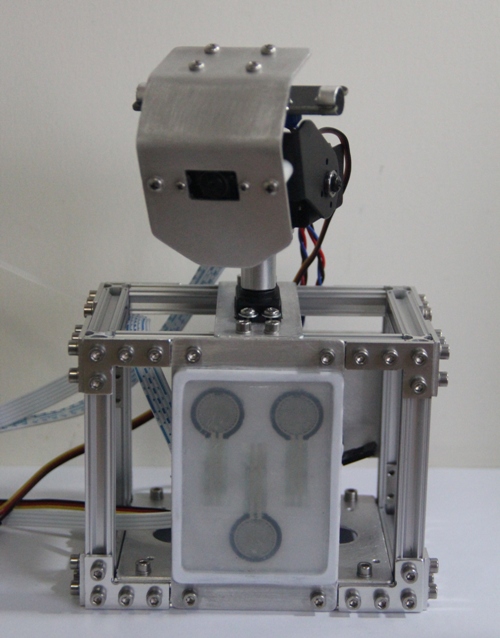

Fig. 6. Front panel with head

July 11, 2013

Fig.7 MicroRax frame finished and base plate assembled

July 12, 2013

Fig.8 Main body with Solar plexus and pan servo. The servo is a HITEC HS-225MG, just weighs 30 g. The main body weighs now 240 g

July 13, 2013

Fig. 9 EMIC-2 text-to-speech module assembled. I made a special holder for it. It can be disassebled prior flight if no live audio down linke is available. After flight it can be assembled again and the robot reports about its experience in Space by reading the stored comments from the SD card

Fig. 10 Cosma got her head

References:

http://science.ksc.nasa.gov/history/mercury/ma-6/docs/ma-6-results.pdf - RESULTS OF THE FIRST U.S. MANNED ORBITAL SPACE FLIGHT. This document includes detailed biomedical data of astronaut John H. Glenn

http://csel.eng.ohio-state.edu/voshell/gforce.pdf - High Acceleration and the Human Body. Physiological effects of high acceleration

http://sugarshot.org/index.html - Sugar Shot to Space project. The first amateur rocket with amateur propellant to reach space. Cosmos' carrier rocket

http://www.nasa.gov/mission_pages/station/main/robonaut.html - Robonaut 2. First humanoid robot in space

http://kibo-robo.jp/en/- Kibo Robot Project. A humanoid robot named Kirobo will be used in the world's first communication experiments between a human and a robot in space

Reports from Space

- Actuators / output devices: 2 DOF head

- Control method: autonomous

- CPU: Atmega2560

- Power source: 7.2 V / 2200 mAh NiMH

- Programming language: Arduino C

- Sensors / input devices: accelerometer, sound sensor, temperature sensor, FSR, AruEye camera, RTC, gyroscope

- Target environment: Space

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/cosma-prototype-1