Hello,

Just going to say Thanks up front for any help. I am no robotics expert and this is really the first time messing with anything like it. I am working on rebuilding a machine at work and right now the feed on the machine is done with hydraulics. It really does not work very well at all. I would like to change it over to a Linear Actuator. It will not need to be very strong at all. I can feed the machine with 1 finger. I just need a constant feed. The tricky part is I want to have 2 different speeds. I want to be able to hit a button. The machine start to feed at its rapid rate for 12" and then slow down to cutting speed for 5" and then retract at its rapid speed. How do I go about doing this?

Thanks,

Hi,

To make your requirements clearer, we recommend that you reply with one or more pictures of the machine in question / setup and maybe some diagrams of what you are explaining. Mechanical setups are usually a very visual thing and a few images can make most design much easier to understand (and prevent misunderstandings when giving advice!).

You can browse our catalog of linear actuators here.

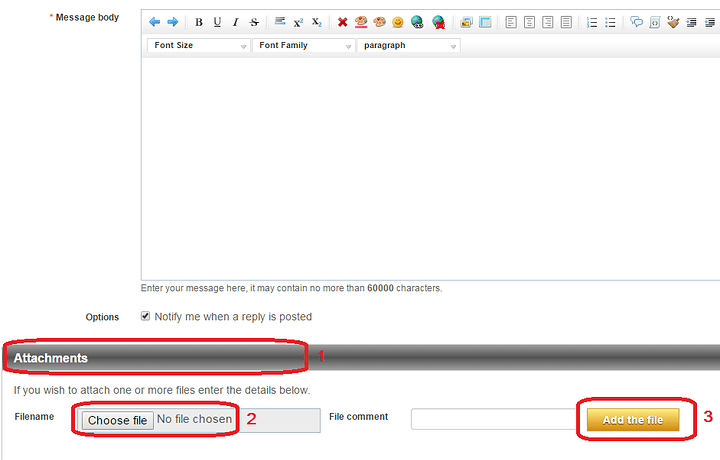

You can attach images to your reply while in Full editor mode. Please see the attached image for details.

Sincerely,

Hello,

Thanks for the reply. I attached some pictures of the machine. Right now the table is just free floating on rails. I disconnected the hydraulics that feed it. As you can see its pretty much just a fancy sliding chop saw for Ceramics. The only thing it is missing is a good feed system. It came with air over hydraulics. It worked but only on one speed and feeding the table up to the wheel on the cutter speed tool forever.

One of my concerns with a linear actuator is the speed difference between rapid and cutting speed. You load the parts and then there is 12" of nothing before it touches the wheel. You do not want to waste 5 mins getting to the wheel. So you need it to go fast. But the actual cutting speed will be very slow. Something like 0.015" per second.

So it needs to be able to:

Rapid at 0.250"-0.500" for 12"

Cut at 0.015" for 12"

Retract at 0.250" - 0.500" for 24"

I would not mind using optical limit switches for the distance it cuts. As some of my parts would be not the full 12" so why cut the full 12".

The internal motor of a 12V linear actuator could be controlled with a motor controller and speed adjusted.

In order to do that, you will need a microprocessor an program you limit-switch in such way that you can get those two speed and we can’t help regarding the programming of such custom project.

You can also use a linear actuator with internal position feedback so you always know (if connected to a microcontroller) the real position where to go fast / slow.

Do you have any background in programming for Arduino platforms ?

I do not have programming experience with that. I have seen the arduino microprocessor’s. If I use a arduino would it need to be connected to a computer all the time?

From what I am reading most of the linear actuators can not go under about 10% of there max speed. So finding a linear actuator that goes as fast as I want and as slow as I want may be a challenge. To get down to 0.015" per second cutting speed it can not go over 0.150" max speed.

The best solution concerning an industrial machine would be to use a BallScrew and a stepper motor.

But this solution would require parts that are not available at RobotShop and some programming as well.

Eric,

I kinda thought the same thing with a stepper or servo and a ballscrew. I just had no idea what would be required to control it and program it. I have messed with steppers for a 3 axis cnc router I rebuilt. But I had the control for that custom built and control it with Mach3 software off a laptop. I do not want to have a computer hooked to this machine.

Thanks Eric,

A stepper motor controller need two signal to make the motor move.

Step: Pulse value which will move the stepper motor on Step. Most motor will have 1.8deg per step so 200 step per turn.

Dir (Direction): This one is simple, which direction to turn.

Once that is said, some motor controller can do microstep which will allow for doing more step per real 1.8deg step for more precision for example.

You will still have to program the Arduino to do the speed according to the number of steps you are at.