I am doing my final year mechatronics engineering project on autonomous window cleaning robot. It is an agv with a robotic arm with 2 degrees of freedom. How do I calculate robot specifications and the weight of the entire structure? I need these to size my motors.

Hi,

We are unsure how to best answer your questions. Here are some questions and comments about your post:

Which specifications do you need to define? Voltage requirements? Power source current? Minimum duration of activity? Window cleaning level (particles removed?)? Technically, the weight of the robot is also a specification. Let us know what you are trying to figure out specifically and we’ll do our best to point you in the right direction.

Well, usually you would sum all the various weights of the components. You can either weight the components yourself or obtain this from datasheets (when available). Of course, if you have custom parts you will have to weigh those yourself. You could also most likely simply assemble a finished product and weigh that then add an amount for the motor/gearbox components.

Indeed. That being said, you will also need to consider the weight of the motor/gearbox into the total weight that needs to be moved around. This of course is a chicken/egg issue. You need the total weight to spec the motors and you need to pick the motors to know the total weight.

The best in this case is to (slightly) over-estimate the weight of the motors based on the “motor type/class” you expect to use and add that to your total weight. Based on your requirements for maximum movement speed and acceleration, you should then be able to find motors that match the required RPM/torque for your use case. Don’t forget that a lot of motors report the “peak” or “stall” torque. For continuous use, you will want to spec your motors so that they use about 20-30% of the stall torque.

For example, [RB-Lyn-63] uses four RB-Hsi-05. These motors weight about 120 g (you can see that and more in the specifications). Do notice that the “rated torque” is much lower than the stall torque. The rated torque is the torque at which you can expect continuous operation for extended periods of time without damaging the motor. If you go above the rated torque, you will need to have moments where the motor is allowed to cool down to prevent damage to it (from overheating).

The following article and tools may help you with choosing your motors:

]Drive Motor Sizing Tutorial Article/:m]

]Drive Motor Sizing Tool/:m]

]Vehicle Speed, RPM, and Wheel Diameter Finder Tool/:m]

We hope this helps.

Sincerely,

First of all thank you.

The project is has the following as subsystems:

Cleaning module (acts as end effector) with automatic timed detergent spray

The agv for detecting Windows andphone carrying the structure

Robotic arm for cleaning

Gantry for moving arm left right

For robot specifications I mean the motors, that is, torque calculations to size the motors at each joint. From torque then I can decide on the type of motor to use. It’s a 3 dof robot - prismatic rotary rotary. The first link is retractable/telescopic, and remaining are rotary.

Yes that’s the confusion as I need weight to calculate motor specifications and vice versa.

That’s just for the robotic arm. Now this robotic arm is mounted on a gantry on the agv frame. That’s why I am starting at top to have a good estimate.

Driving motors also need to be sized and before that, wheel selection.

The agv will work on a ceramic surface(in malls). Is there a specific way of choosing the right size for the wheels or just whatever is available from standard ones?

Thanks for the extra details. This certainly helps figure out better what you need info-wise.

We originally misunderstood your request and thought it was only about the motors driving the AGV frame.

Here are more comments/answers about your details:

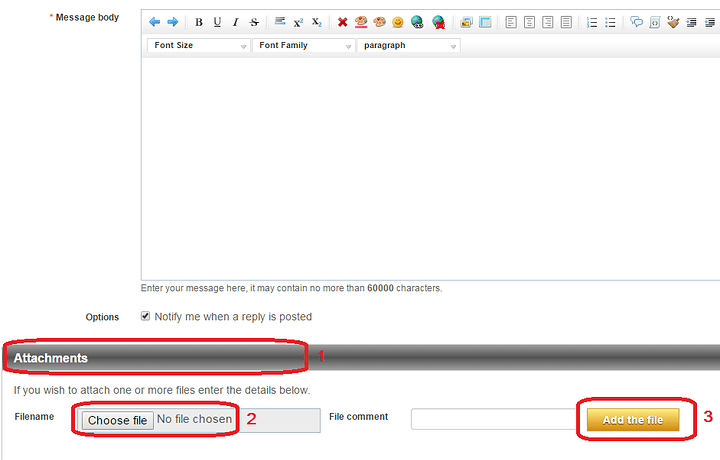

Well, that certainly makes the system easier to picture. Also, do not be shy adding pictures to your post. Pictures often make it much easier for others to help you out since it makes things clearer. The more clear your questions, the more likely you’ll get quality response!  You can attach files (including pictures) using the Full editor mode when writing (or editing) a post. See the attached image for details!

You can attach files (including pictures) using the Full editor mode when writing (or editing) a post. See the attached image for details!

The best for a robotic arm with 3 DoF would be to start from the end effector and make choices / set requirements. Therefore, start with what will be carried at the end effector. If the device there is, lets say, at most 1 kg then you can calculate the torque required (and support parts, such as bearings, gears, etc.) to use such a weight.

From there, you will have an assembly+payload weight for that junction, you can now spec the one before it (also rotary). Once you have chosen what is required (and therefore the motors, too), you should be able to figure out the total maximum weight at this point. You can then figure out what stresses will be place on the retractable/telescopic link. Be careful of this, since the force require to extend/retract will change based on the angle to gravity of your link. Even if this link is always pointing straight “up” (parallel to gravity), the two rotary DoFs may move the payload off center, causing force sideways. Make sure whatever is driving your retractable link can take these forces.

See answer above. Also, when doing motor specs, make sure to use the motor’s rated torque, not stall torque! If no rated torque is provided (only stall), you can use around 20-30% of the stall torque as a rough estimate.

Very good idea. Start at the simplest point (end effector/payload, usually) and work your way down. From bottom (1 specific feature, such as the end effector)) to top (the entire system itself, such as driving torque required), basically, in terms of system complexity.

Follow the procedure describe above to get your total weight of the entire system. Once you have that, check our previous post!

We recommend choosing a standard wheel size for simplicity/cost that works for you. Please note that the wheel will act as a gear-up (increasing RPM, reducing torque), so take that into account, too!

Good luck with the project!

Sincerely,

See the image attached to the post above. It should show you how to do exactly that!

Not quite. Take a look at the following tool and tutorial:

robotshop.com/blog/en/robot … lator-9712

robotshop.com/blog/en/robot … orial-7152

Working backwards from the end effector which is in contact with the glass, the worst case scenario is where L2 and L3 are horizontal to the ground. Note that this should not be the case as any other angle will cause the end effector to lose contact with the glass.

You can use the tool to estimate the torque needed by each of the two actuators at A2 and A3. Put estimated values and once you find real actuators and get a better idea of their weight, put in the new values and re-calculate.

The sum of L1(max) + L2 + L3 needs to reach the farthest corners of the glass, whereas LB (base height) + L1(min) - L2 - L3 = 0.

The force needed by the telescopic lift would need to be calculated after you have designed a lot of the arm, chosen actuators, materials etc. to know the total load, and then use a safety margin.

You might greatly simplify your design by having a single telescoping actuator positioned at the center of the glass which rotates. This would reduce the “arm” to two degrees of freedom, plus whatever you need for motion of the base.

I actually want to simplify further by eliminating the robotic arm and replacing by a rack and pinion mechanism for cleaning.

But I need it retractable. Not sure if I go with this simpler design cause if the choice of the lifting mechanism. My options are zipper mast, telescopic spiralift, scissor lift

From the Robot arm calculator, I do not need to add all the weights acting … I just replace individual weights in the calculator and lengths?

The torque values if the torque needed for each actuator, am I right?

Not sure how a rack and pinion system would work.

You would start with the weight of what’s being held as A1, the length to the actuator as L1 and the weight of the link as M1. The est. weight of the actuator as A1 and so forth.

The calculator would give an idea of the torque needed to maintain it in a horizontal position, so be sure to add a margin of safety.