I've started a new robot project.

(I blame you guys for the inspiration!)

I'm building a Jansen walking robot from scratch. This video shows both the cnc cutting a leg connector, and the parts cut during the video.

Update 1/14/12

I got a big set back. After spending the gist of my weekend trying to cut the legs. The cnc I'm using appearantly can't handle my 3D leg design. It cuts 2D parts great but not 3D. I think this problem is because I'm cutting aluminum with a hobby mill. So I'm gonna have to put this project partially on hold till I find a machine shop to cut the legs for me. I'm not quiting this project. I have half the leg connectors cut, and 2/3 of the drive gears cut. Mean time I'll finish cutting the rest of the 2D parts.

I guess the bottom line is I'm trying to make a big metal monster on a college student Ramen Noodle budget! lol

Update 1/28/12

I started a new job but have yet to get my first paycheck. So funding for this project is on the way. (Yay!) I picked up a couple large DC brushed motors at a local junk store for $5 each. They are from battery powered weed eaters and claim to be 2/3 hp peak at 24v. I expect them to be around 1/3 hp continuous, but have not yet load tested them.

Update 2/4/12

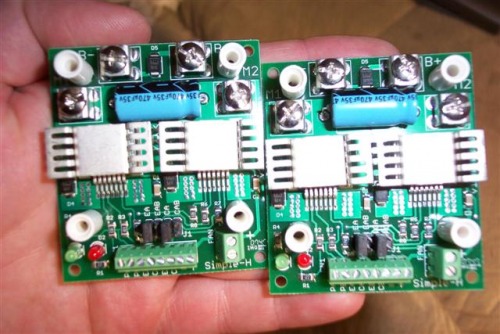

I was sitting here chatting with LMR members about buying a motor controller for this project. A bit later I get this text "hey buddy I'm gonna stop by to give you something" from my friend with the cnc machine. He shows up with a pair of motor controllers which just happen to be the same exact ones I was talking about buying on LMR chat! Turns out he had to place an order and picked them up for me since he knows all about my walker project. (gotta pay him back for them, but still....) So now I've got motor controllers!

These motor controllers specs:

Brand: Robot Power

Model: Simple H

Rating: 20A continuous, up to 28V

Many more updates will follow!

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/building-a-walker