Does the -R version of the L16 support a 3.3v signal on the control input?

The data sheet says 5v but is this could be a legacy logic spec.

2 other questions:

What is the stall current of the 6v RC version?

If the control pulse signal goes outside of the 1mS to 2mS range, does the servo stop without damage?

Regards

Hello @bearbait and welcome to the RobotShop community,

No, the RC version only supports 5 Volt pulses.

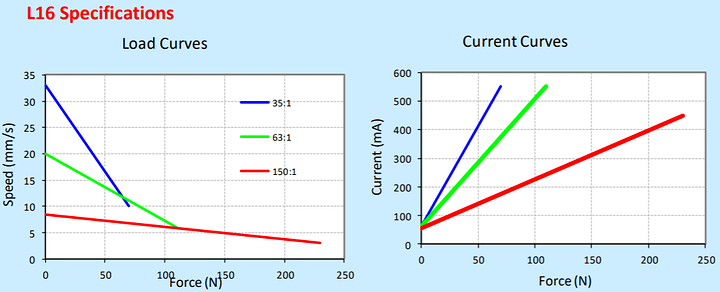

The stall current depends on the version (gear down), you can check the curves here:

Thanks for your prompt response, however, the answer that you gave to the stall current question does not tally with the data sheet. According to the data sheet “Stall Current 650mA @ 12V”. None of the curves go to 650mA. Also, the R version is a 6v motor and the quoted current is for a 12v motor. Can I assume that the 6v version takes approximately twice the 12v current?

You also did not address the question regarding what happens when the pulse width goes outside the 1mS to 2mS range. Can this cause damage?

Regards

Can I assume that the 6v version takes approximately twice the 12v current?

That would be a good approximation. For reference, the L16-R 150:1 version has a stall current of 1A @ 6V.

what happens when the pulse width goes outside the 1mS to 2mS range. Can this cause damage?

Yes, that could cause damage.

The R version of these actuators functions like a servo motor so if you want to find the “limits” you can follow this procedure:

To find the limits, use the lowest possible supply voltage at which the servo moves, and gradually increase or decrease the pulse width until the servo does not move any further or you hear the servo straining. Once the limit is reached, immediately move away from it to avoid damaging the servo, and configure your controller to never go past the limit.

Thanks for that. I have ordered a unit to try out.

Regards

RE: Actuonix L16—R purchased last week, 2 questions:

- Is there a minimum and/or maximum PRF (pulse repetition frequency) that the device will respond to? Does not seem to like anything below 200Hz, loses the plot quite easily.

- Does the device use some form of PID (Proportional-Integral-Derivative) control? The speed of the shaft seems to drop dramatically as it approaches the correct position!

Regards

Those specifications aren’t mentioned on their documentation, however, because of the behavior, you mentioned you seem to be on the right track assuming it has some sort of control loop. Anyway, if you need more details about the actuator we recommend contacting the manufacturer directly at [email protected].

Ok, thanks, will do