This is 3D printed robot out from printrbot. I am still trying to learn how to adjust those setting with different material. As you can see the quality is not that perfect yet. Another reason to build this one is trying to use bearing in between the servo and bracket. Last hexapod project was weak in the joint of servo horn.

I am using Flyduino 12 Servo controller(the one below) with 12 9G servos.

Yellow parts are joints for servo bracket. Using ABS material and red parts are PLA material.

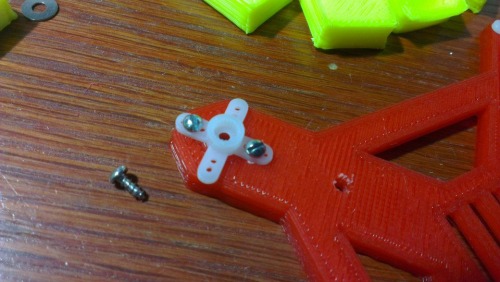

The bearing I use is "Flange Bearing 3x6x3mm".

Using M2 tap screw to lock servo horns. I have upload the sketchUp file in case who ever want to take a look or print them. You are free to modified to match your needs. The reason why I didn't submit this chassis to thingiverse is all these size for bearings, screws and servos are vary. Not everyone are having same hardware.

Assembling parts and try to find the better place for the board. Actually I am having problems to use this controller board.

I decide to put everything inside chassis and it almost complete. Tested by using servo tester and those 9G servos has enought power to left up the whole thing with no problem. These filament is not that heavy from the way it looks.

Compare to the previous project. This one is actually slightly larger than hexapod.

Now, I am still trying to figure how this 12 servo controller works. Sorry for my English to describe the problems :p

The problem I am having now is the position from the board. For example, these 9G servos has 90 degree rotation and we usually using Servo library which has 0~180 range input. However, in my case, it only accept the input in between 0~40. Also, servos only works around 45~60 degree. It won't go over 60 degree and won't go below 45 degree.

Here is the info about this board FLYDUINO 12 SERVO CONTROLLER.

The main reason why I want to use this board because it has compact design include XBee slot and servo pins. If this board doesn't work out well I will looking for next options. If anyone of you has experience about this board or knows whats going on please let me know. Thank a lot!

- Actuators / output devices: 9G Servos x12

- Control method: Remote via XBEE

- CPU: ATMega128

- Power source: 7.2 lipo with UBEC to regulate down to 6V

- Sensors / input devices: xbee

- Target environment: indoor

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/3d-printed-quadruped