Salvaging Parts

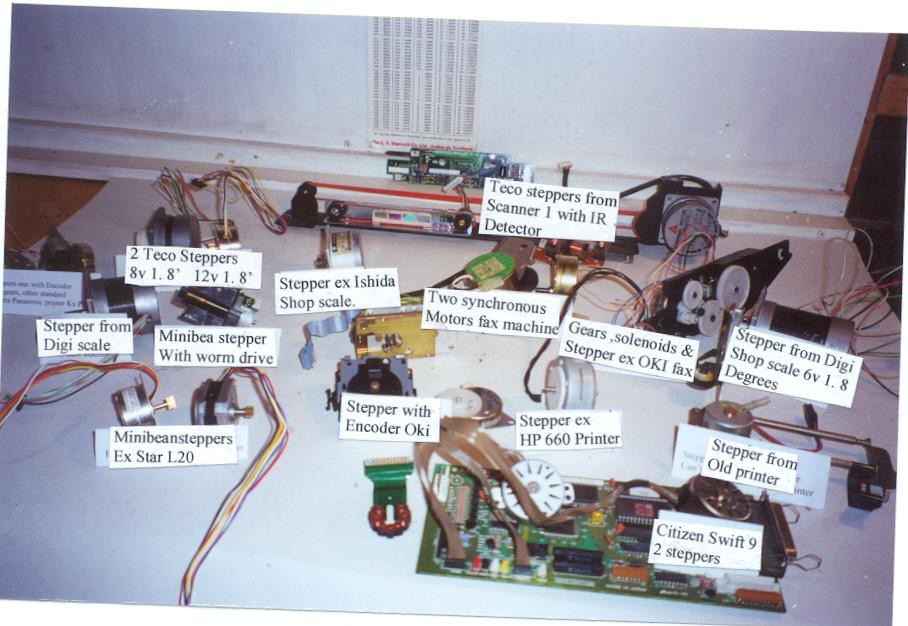

Click for bigger pic.

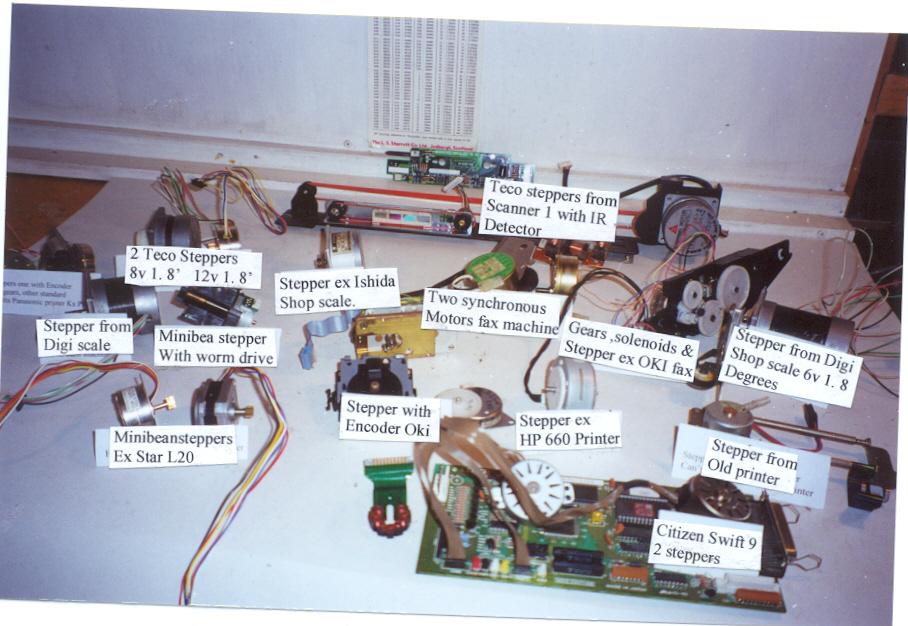

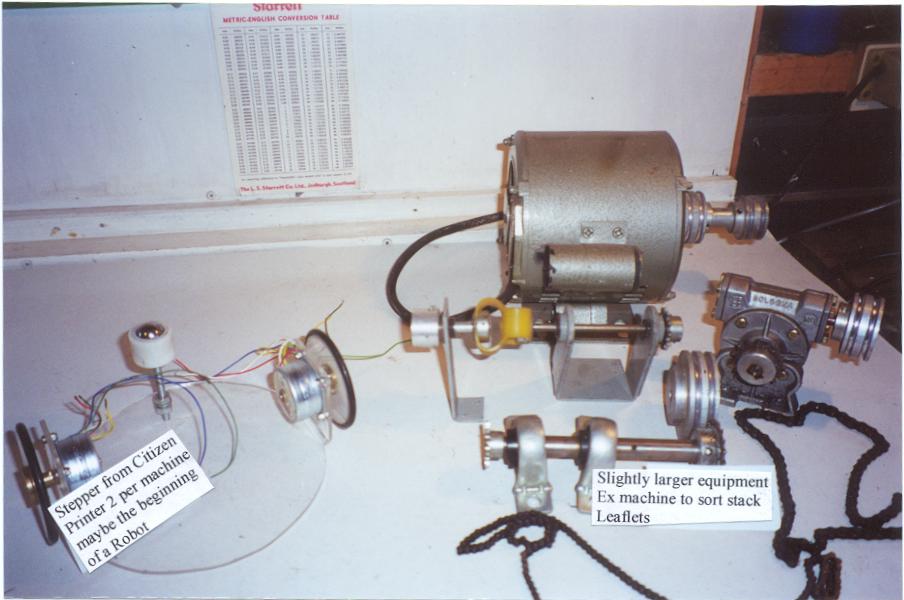

Click for bigger pic.

My interest in Robotics began when I decided to try and introduce some

new interests to my Grandsons, in order to get them off their Play

Stations and computer games. The idea was good but, to some extent,

backfired -- I was hooked and can’t leave it alone now. I am still a

bit of newbie, and have lots to learn. I have built two six-legged

robots to date. For the next experiment I thought I would like to build

a wheeled robot. When I started to look around for stepper motors,

etc., I found the only source would cost about $100+. There are no

surplus dealers around here, like you have in US. I had a couple of

TECO printers and a old CITIZEN so I decided to sacrifice them for a

good cause.

I thought other enthusiasts maybe be interested in my experiences

looking for parts. You may see a machine going cheap and not know what

it contains.

The TECO printers were really good, containing two larger steppers and

two smaller ones. That gave me two pair. The CITIZEN also had a couple

of nice steppers

with an encoder wheel attached (used these in the end to start the new

project).

After dismantling the three printers, I decided to pay the local tip

(local dump) a visit. They have a recycling depot, as they call it,

where you can purchase

selected rubbish, that has been cast off by other people, for a minimal

amount by offer. After wandering around I spotted a large floor model

KONICA copier sitting in a corner (had just arrived in). Gave them an

offer of $5, "It is yours" the TIPPY (trashman) said. Luckly I had some

tools with me, so I set about to partly dismantle the copier to get it

in the van. As you will see from the list below

there was a mountain of parts in it. I had a couple of small SHARP

copiers given to me, but these were a disappointment. I dismantled one.

Parts yielded were one AC 1425 rev motor and a few micro switches. The

second one I took to the tip. While dropping off the copier,

I had another browse around the tip and I spotted a HP 660 Inkjet

Printer on the bench. It appeared to be in new condition. I checked the

ink cartridges and went to dicker on the price. "New machine", said the

TIPPY, "dumped by dealer because it was faulty. Cost you $10". I made

the deal, and got two new cartridges and a nice double ended shaft

stepper. I would like to have two of these steppers with the double

ended shaft, but haven’t been able to locate another dumped HP printer.

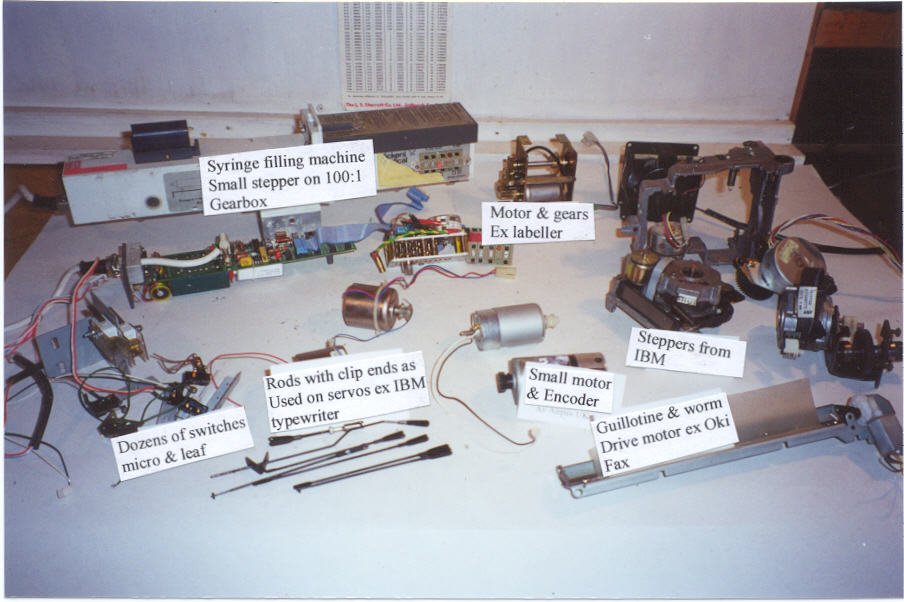

Click for bigger pic.

Weeks went by and I acquired a few more odds and ends.

An IBM electronic typewriter yielded four steppers. IBM Electric

typewriters haven’t much to give. A very interesting piece of equipment

was a syringe filling unit made by VICTOR Medical UK. It had a small

stepper attached to a very nice 100:1, beautifully made, brass gear

box. I have three of these. I picked them up at the local hospital.

They were lying outside waiting to be dumped as they were obsolete

(1988). Another interesting stepper was a small one out of a OKI

Microline 182 this was built into the print head and was only 8mm thick

and 40mm dia. A reversible gear train was mounted on one side and a

encoder wheel and sensor built into the other.

With the amount of junk I have accumulated I could just about go into

the surplus market!

Dot-matrix printers vary in price between $2 and $5. Some have two

identical steppers, otherwise you have to buy two printers of the same

model. Most steppers from printers have a pinion fixed to the shaft.

They can easily be removed. First wrap a wet rag around the stepper

to keep it cool, then heat the gear with a small torch, like the gas

soldering irons, usually once it is hot enough the gear will drop off

when held upside down. I made a small puller, but found I didn’t need

it. When dismantling it is best to leave all the cables intact,

especially servos motors, as they can be plugged in to the PCB after

you get rid of the mechanicals.

I use the TECO printer PCB to check out servos, by closing the micro

switches the servos can be run continually or pulsed.

Waiting on the bench is a Panasonic colour printer model KX P2124 with

a LCD readout,(another five bucks) of stock. I am a bit reluctant

to dismantle this one as it is in excellent condition, dumped from one

of the local Colleges.

Below is a list of some of the equipment I dismantled.

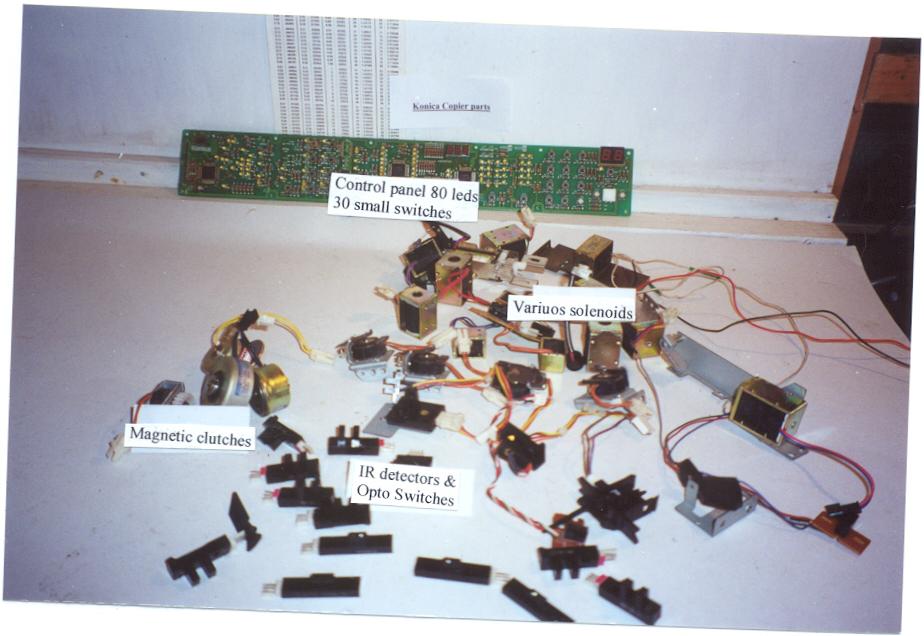

Click for bigger pic.

1. Citizen Printer about 1998 mislaid model no.: Two Minebea stepper motors with brass gears attached, one motor had an encoder Wheel attached. Two Opto switches.

2. TECO Printer: Two Servos - one large servo made by TECO, 8volts, 1.8 degrees, 400mA and a Small Minebea, 12volts, 1.8 degrees; 50 ohm coils; the TECO servos has a 6mm shaft Minebea 3mm shaft.

3. Microtech Scanner model "Scanmaster": Large Teco stepper, 12volts 1.8 degrees, 400mA, belts and pulleys attached; Very small stepper with belt drive; IR detector.

4. Large Konica copier floor model - Gold mine of parts.

· 300rpm geared motor.

· 1425 rpm motor with encoder wheel attached.

· 200rpm geared motor.

· FDK stepper with external gear train and small solenoid for reversing gears.

· Minebea stepper with external gear train.

· Large stepper, 4"diameter by 2" thick made by Japan.

· Servos, 24 Volts.

· Nippon Pulse Motors Servo 12volts.

· Large selection of nylon gears all sizes and shapes.

· Front control panel contained 80 yellow LED’s and 30 small switches.

· Selection of various Opto switches and IR detectors approx. 20.

· Small micro switches.

Click for bigger pic.

5. Star L20 printer: Sanyo Denki square shaped stepper; Minebea stepper; Sensors and micro switches.

6. Small Sharp copier: Small AC moto,r 1425 rev; micro switches This was a disappointment. I had two didn’t bother with second one.

7. Victor Medical syringe filler: Small stepper attached to a nice gearbox with brass gears 100:1 ratio - 3x

8. Digi Teraoka shop scales model SM 40: Large stepper for barcode printer made by Teraoko 75mm long; 55mm diameter toothed belt pulley 6volts 1.8.

9. Another Digi scale: SM60 Stepper made by Teraoko; 55mm long 55mm diameter 6Volts.

10. Ishida shop scale: Stepper by Japan Servos Co., 12 volts, 30mm long 55mm diameter.

11. Citizen Swift 9 Printer: Two Sanyo 12volt Servos micro switches.

12. OKI Microline 182: One servo made by OKI, 35mm long 15mm diameter, 12volts 7.5 degrees; Small slim line servo, 8mm long, 35mmm diameter, double ended shaft reversible gear train,z encoder wheel attached.

13. OKI Copier: Two 120 Synchronous motors, one with gearbox the other with gear train size of average stepper motor.

15. IBM electronic printer: Four middle size servos with gears and other fittings.

16. IBM Electric typewriter: not much in these, one 1425 rpm motor quite; A few stays with clip on ends like the model servos fittings.

Click for bigger pic.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post