Raspberry Pi-based Neuromuscular Biomechanics Test System

The test system, developed by The Neuromuscular Biomechanics Laboratory at the University of Wisconsin-Madison, is a shear wave tensiometer that can track tendon forces inside the body during dynamic activities powered by Raspberry Pi 4B and MCC 172 IEPE.

Why Raspberry Pi?

The traditional benchtop shear wave tensiometer measures muscle-tendon loading during motion in laboratory environments. A portable Raspberry Pi-based tensiometer allows the data acquisition to be performed anywhere. The applications for tensiometers can then be expanded to various fields. For example, a portable dihedral tensiometer measures water tension in substrates

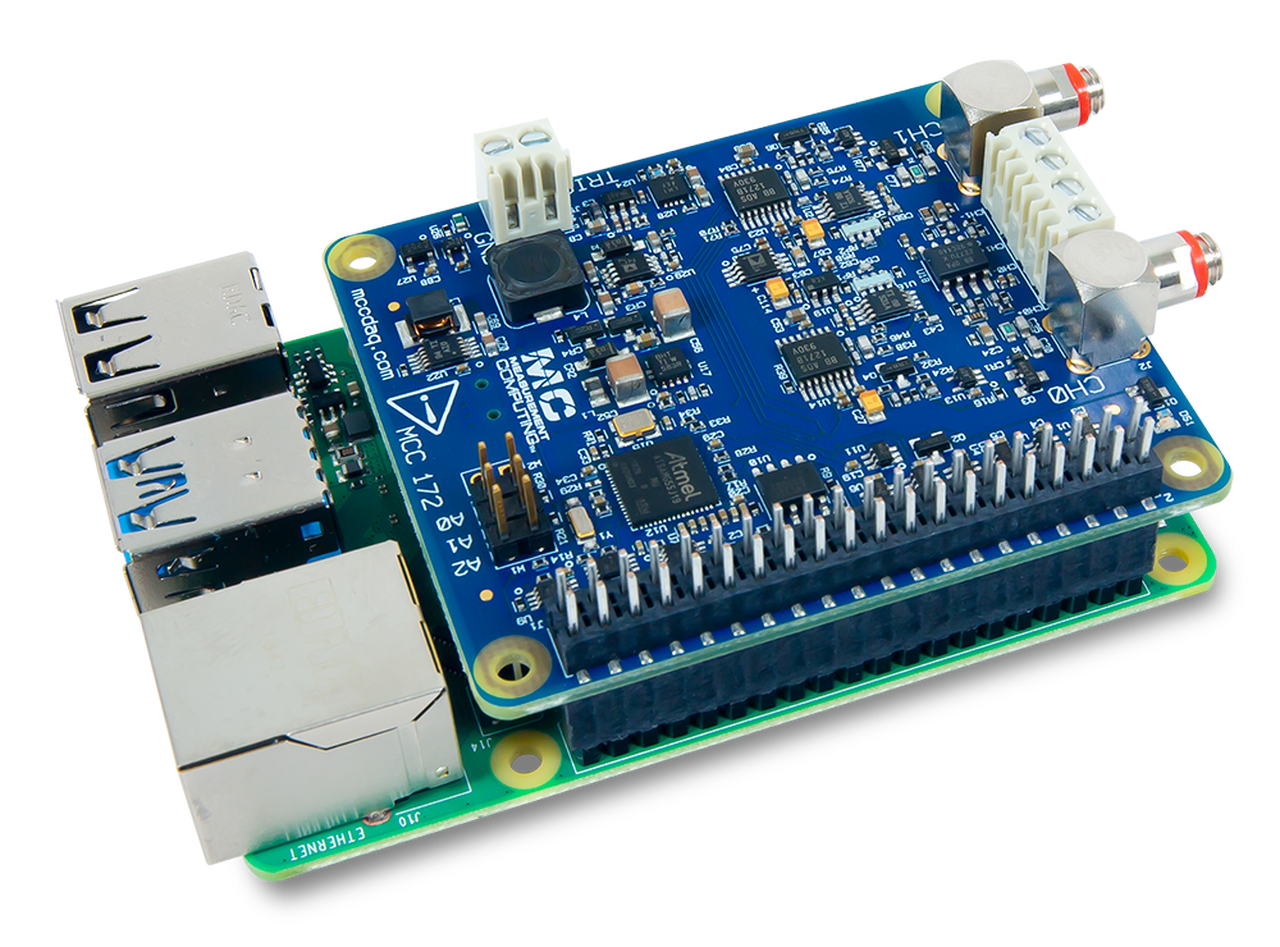

MCC 172 IEPE Measurement DAQ HAT

The MCC 172 features two channels for making sound and vibration measurements from IEPE sensors like accelerometers and microphones. The two 24-bit differential analog input channels simultaneously acquire data at rates up 51.2 kS/s. Users can turn IEPE excitation current on or off. Each channel has a dedicated A/D converter. Both ADCs share the same clock and are synchronized to start conversions at the same time for synchronous data. Multiple MCC 172 HATs can be synchronized to a single sampling clock. The clock is programmable for sampling rates between 51.2 kS/s to 200 S/s. The trigger input (terminal TRIG) is used to delay an input scan until a specified condition is met at the trigger input.

The MCC 172 features two channels for making sound and vibration measurements from IEPE sensors like accelerometers and microphones. The two 24-bit differential analog input channels simultaneously acquire data at rates up 51.2 kS/s. Users can turn IEPE excitation current on or off. Each channel has a dedicated A/D converter. Both ADCs share the same clock and are synchronized to start conversions at the same time for synchronous data. Multiple MCC 172 HATs can be synchronized to a single sampling clock. The clock is programmable for sampling rates between 51.2 kS/s to 200 S/s. The trigger input (terminal TRIG) is used to delay an input scan until a specified condition is met at the trigger input.

The open-source MCC DAQ HAT Library of commands in C/C++ and Python allows users to develop applications on the Raspberry Pi using Linux. The MCC DAQ HAT Library supports operation with multiple MCC DAQ HATs running concurrently. Console-based and user interface (UI) example programs are available for each API.

The Raspberry Pi-based Tensiometer

In order to create the shear wave tensiometer, the following solution is used:

- For one tensiometer, two single-axis accelerometers are sampled at 51,000 Hz, which is done on a single MCC 172 IEPE Measurement HAT.

- For multi-tensiometer experiments, two HATs are used to acquire data on two tendons simultaneously.

The system consists of a Raspberry Pi 4B, two MCC 172 HATs, and two single-axis accelerometers. Triggering is supported remotely by a Pololu Wixel, a general-purpose programmable module featuring a 2.4 GHz radio and a USB interface. The system was programmed using Python™ scripts for continuous, multi-HAT acquisition. Post-processing of data is done in MATLAB®.

The case study is available on https://www.mccdaq.com/appnotes/an123.aspx

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post