M.I.T.'s Rapid Liquid Printer

M.I.T.'s Self-Assembly Lab, in collaboration with Steelcase and Christopher Guberan, have displayed the results of a new 3D printing concept they call "Rapid Liquid Printing". A video is always best to show how it works:

[embed]https://vimeo.com/211513776[/embed]

[embed]https://vimeo.com/245973170[/embed]

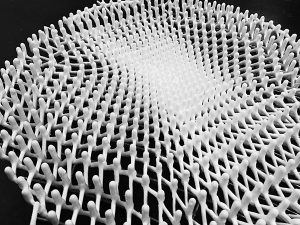

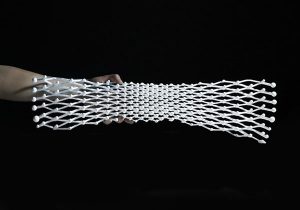

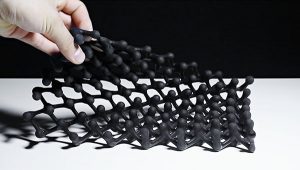

Additional examples of what they have been able to create:

A gel acts as support for material being extruded. Interestingly, the gel "self heals", which allows the nozzle to move continuously within the gel and not disrupt the printing process or support by creating voids or tunnels. Skylar Tibbits, co-director of MIT's Self-Assembly Lab:

|

|

|

|

3D printing hasn’t taken off as a mainstream manufacturing process for three main reasons: 1) it’s too slow compared to conventional processes like injection molding, casting, milling, etc. 2) it’s limited by scale – although it’s good for creating small components, it’s not possible to produce large scale objects 3) the materials are typically low-quality compared to industrial materials. Rapid Liquid Printing addresses all of these limitations: it is incredibly fast (producing structures in a matter of minutes), designed for large scale products (you can print an entire piece of furniture) and uses real-world, industrial-grade materials.The machine itself, created around a small industrial robot arm, can be scaled to any size:

The gel is similar to a hair gel or hand-sanitiser and has two key functions. The first is that it can suspend objects so that we aren't fighting gravity and we don’t require layer-by-layer printing or support materials, which are time consuming to print. This means that a part can be printed quickly within the gel and then removed and simply washed off with water. The second is that the gel self-heals after the nozzle passes through. This allows you to continuously move and print within the gel and not create tunnels or cavities which would fill up with printed material.Sources: selfassemblylab.mit.edu/rapid-liquid-printing/ selfassemblylab.mit.edu/liquid-printed-products/

Thanks for helping to keep our community civil!

Notify staff privately

You flagged this as spam. Undo flag.Flag Post

It's Spam

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post