Lynxmotion's A4WD3 Rugged Mobile Robot Platform

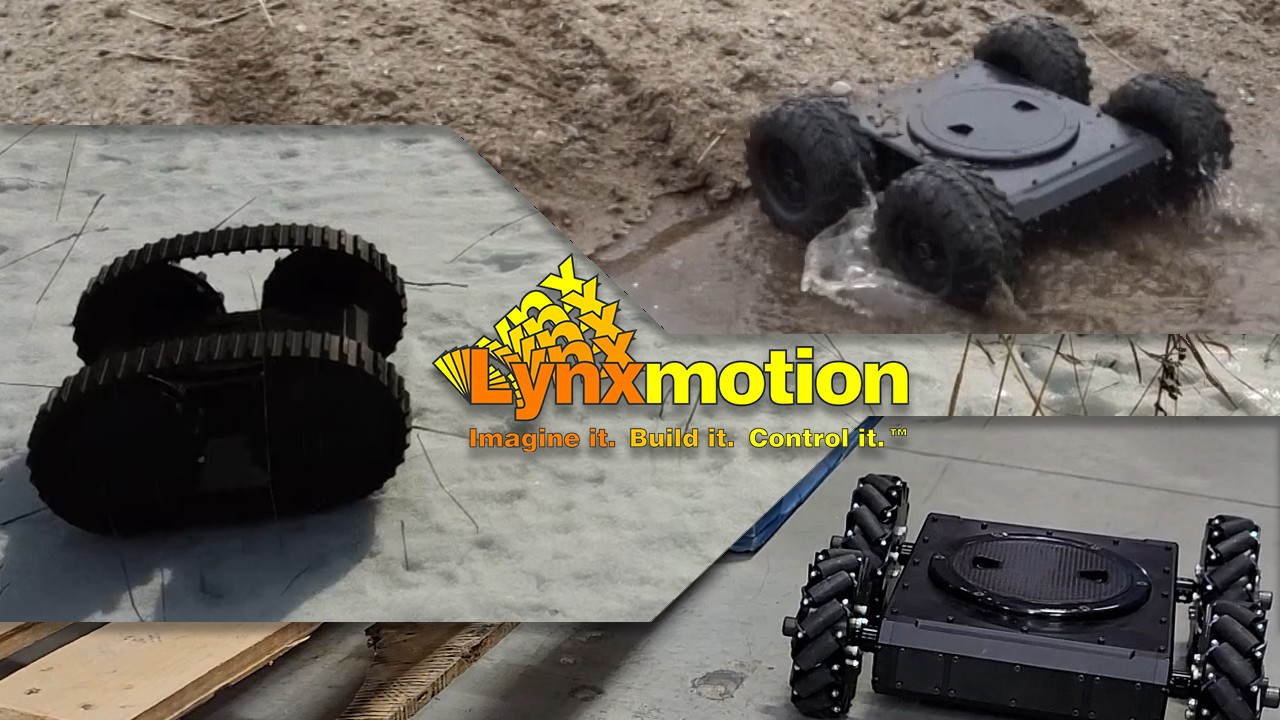

RobotShop is proud to announce the release of the next generation of Lynxmotion A4WD rovers: the A4WD3! This latest semi-professional design includes a large rugged machined frame (aluminum and G10) which is dust and water resistant and a large access hatch. Three different configurations use this frame: wheeled; tracked and Mecanum.

This medium sized robot can be used for RC or as a development platform for autonomous applications. How did Lynxmotion's rover lineup evolve? Let's look at the history:

4WD, 4WD1, 4WD2 Rovers

First generations of Lynxmotion rover included the 4WD1, 4WD2 and 4WD3 kits. These were made of laser-cut polycarbonate panels which were slotted and screwed together.

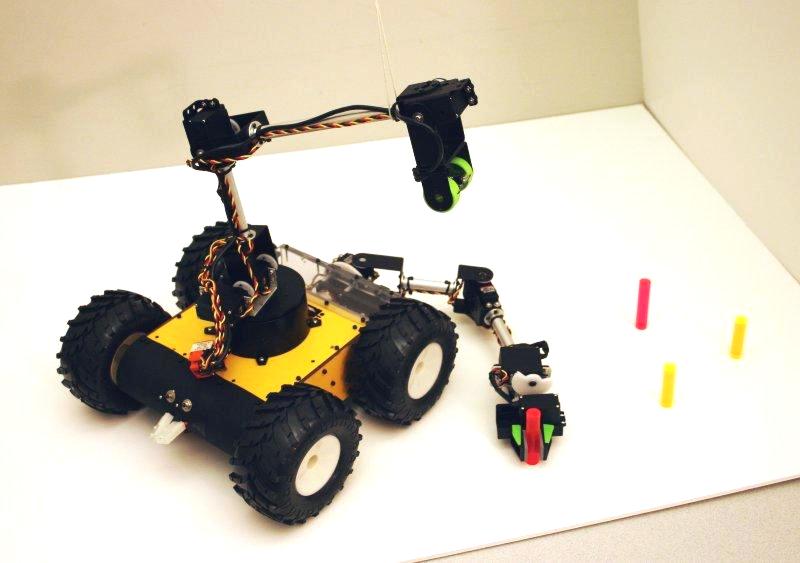

Customers used these platforms to quickly prototype RC, semi-autonomous and fully autonomous mobile robots for a range of applications. Lynxmotion's modular robotic arms and accessories could be mounted atop as well.

A4WD1

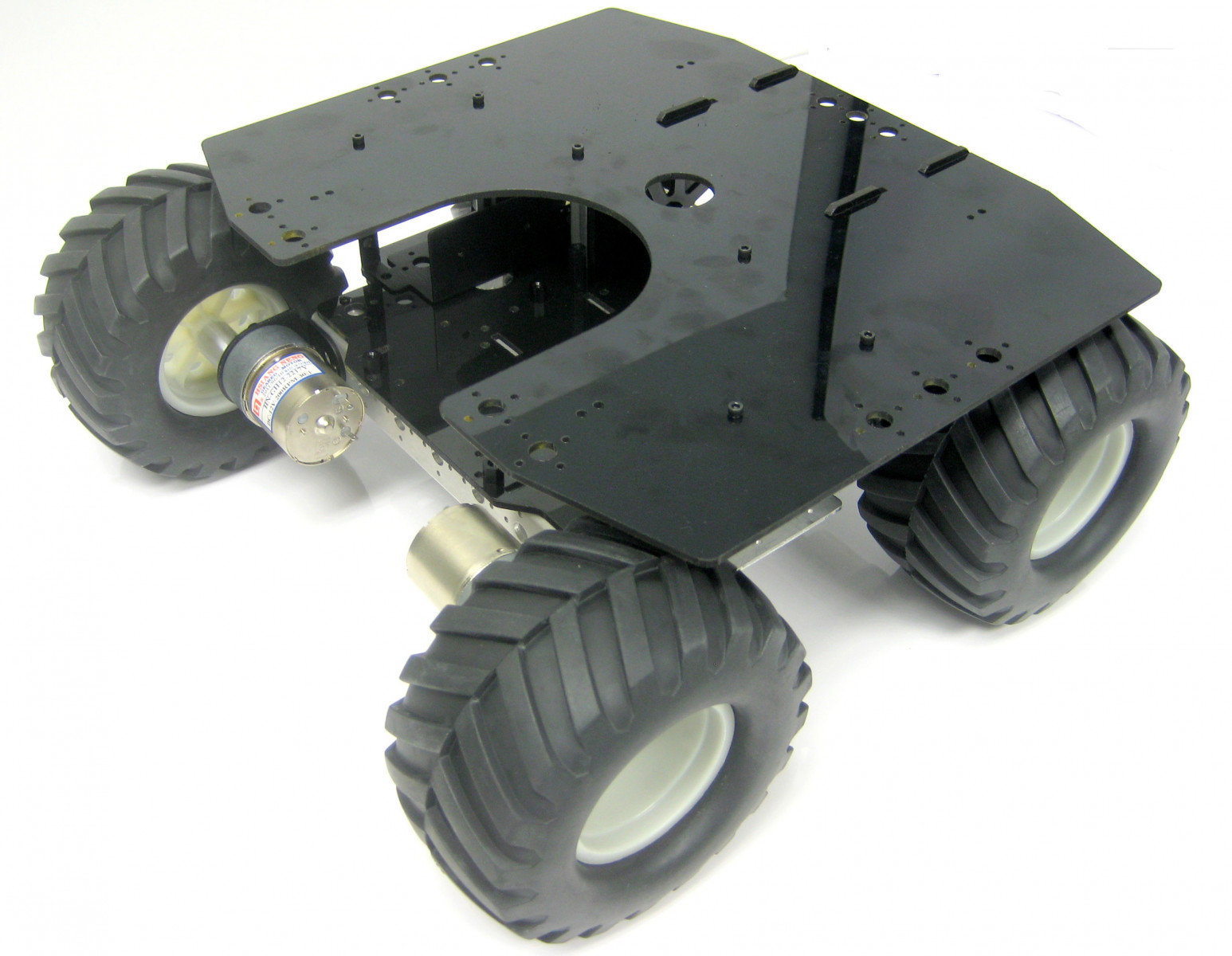

The A4WD1 evolved from the 4WD3 and was updated to be stronger, more easily produced and incorporate the SES mounting pattern. The frame was made of bent aluminum which was anodized black, and the top and bottom are from durable black polycarbonate. Customers use this frame for everything from autonomous development platforms coveted in senors to remove inspection. Add-on decks allow for electronics to be stacked, creating additional mounting space and options. The A4WD1-MTS variant came about after enough customer demand for a tracked version of the A4WD1. This rover incorporated the same tracks used in the Lynxmotion Tri-Track but made use of the Modular Track System (MTS) sprockets.

A4WD2 / A6WD2

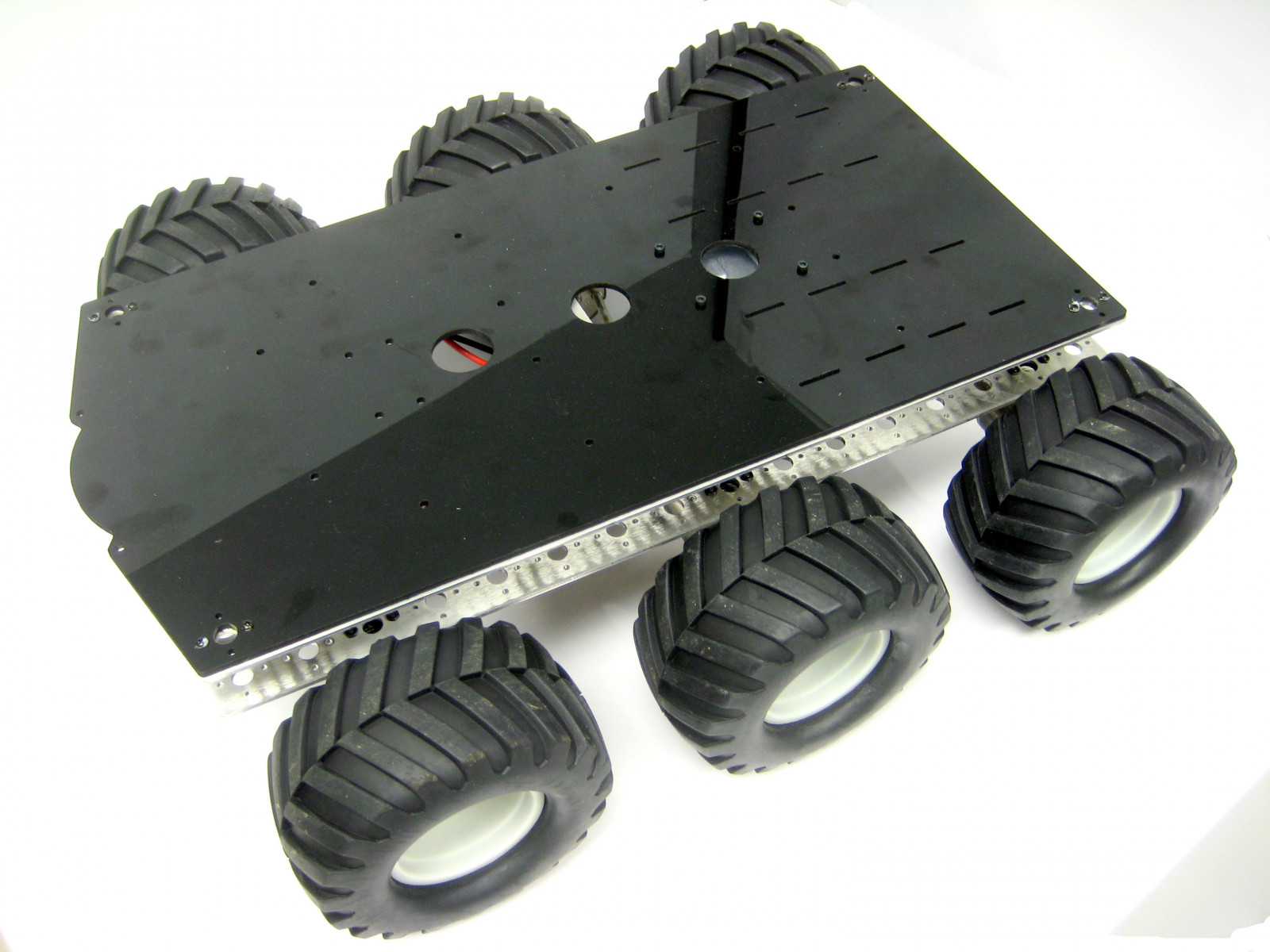

The A4WD2 and A6WD2 were released as modular, minimalist concepts designed around Lynxmotion’s custom aluminum extrusions. Designed to integrate Lynxmotion's Servo Erector Set (SES) modularity, users could add SES-compatible parts around and on top of the rover, making it easy to add sensors, robotic arms, additional servos and more for their custom applications. The platform retained the standard spur gear motors, hubs and wheels.

A4WD3

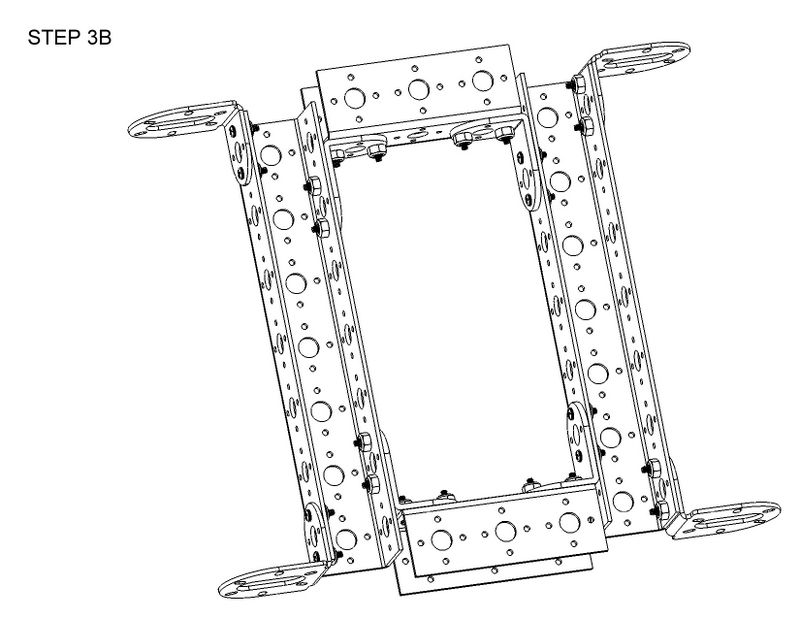

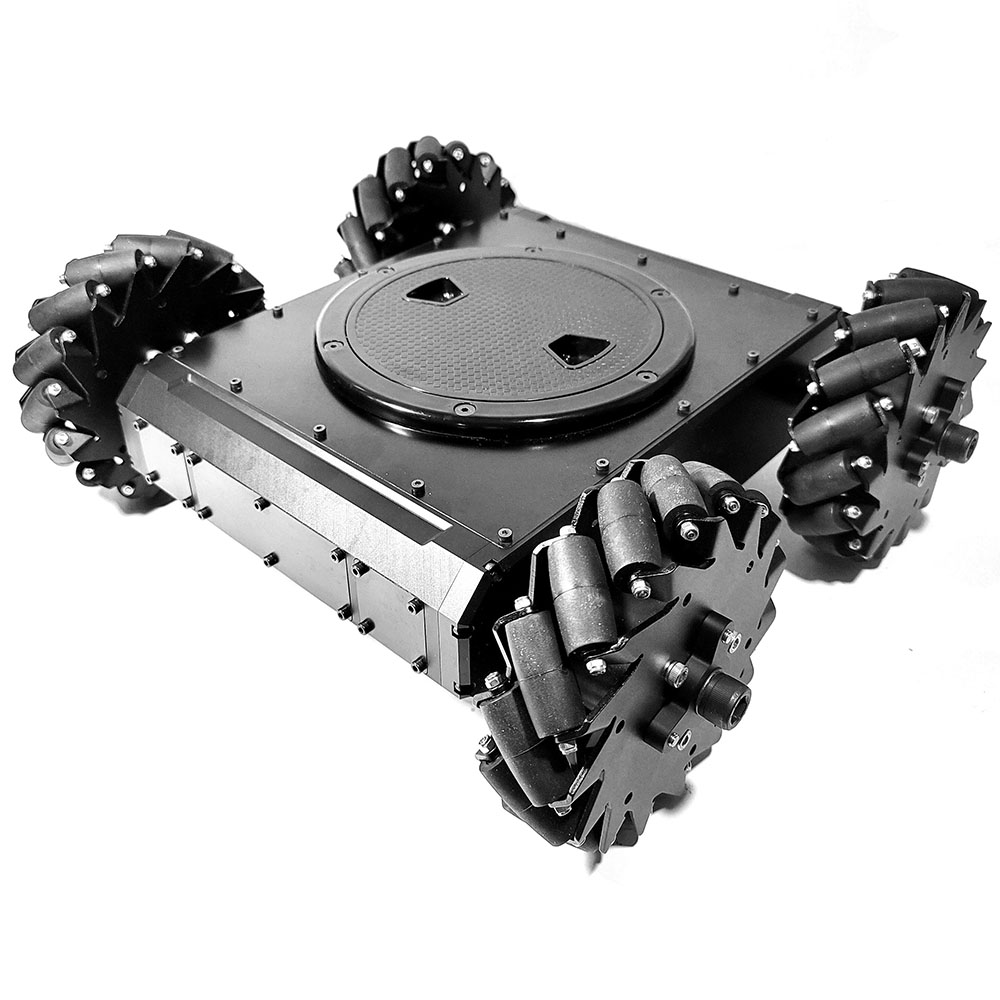

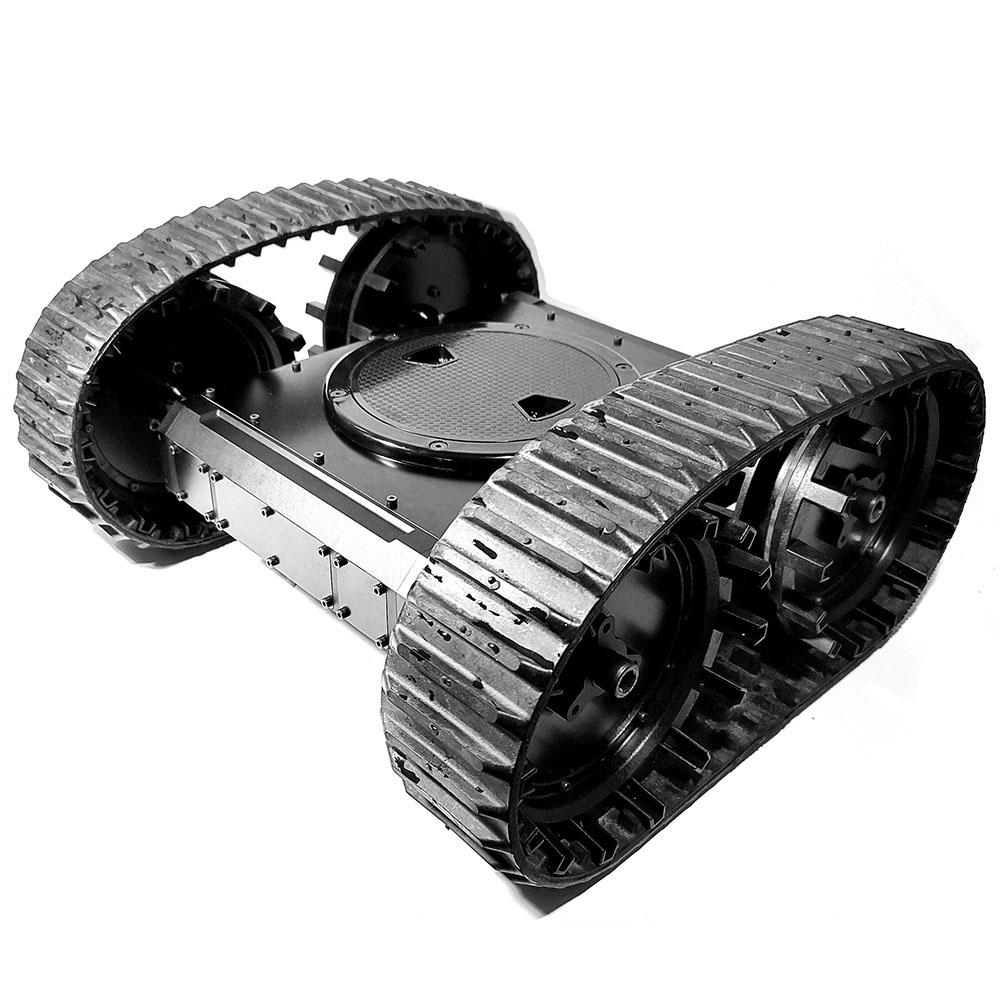

The new Lynxmotion A4WD3's purpose-built frame allows it to be used effectively in three different configurations: wheeled, tracked and Mecanum. Each opening is sealed either with rotary shaft seals or rubber cord, helping to make the internal compartment dust and water resistant.

So how do the A4WD3 compare to its direct predecessor, the A4WD1?

-

Larger overall size using a machined frame made from billet aluminum.

-

Significantly more powerful planetary gear motors with integrated rear shaft magnetic encoders.

-

One frame for three configurations: Tracks, Mecanum and Wheeled.

-

Water and dust resistant (rubber cord, shaft seals, watertight hatch).

-

G10 replaced the polycarbonate which was used on previous top and bottom frames.

-

Easy twist-off access hatch rather than four thumb screws (used on the top of bottom).

-

Multipurpose panels on the front and rear (ex. optional LED lights).

-

Multipurpose internal mounting plate for electronics.

-

A4WD3 tracks are continuous, reinforced rubber vs. modular plastic and rubber tread on the A4WD1.

-

Both can operated inverted and are symmetric front and back.

-

Both can be used for autonomous robotic development or RC applications.

The A4WD3 is intended to be used for a variety of different semi-professional roles, from RC inspection and surveillance to fully autonomous robotic development. Although not intended to be fully watertight (ie submerged underwater), the frame's internal cavity which holds the electronics, motors and battery is well protected against dust and splashes. The tracked version offers the greatest ground clearance as well as traction and can be used on sand, forest floor and light snow. In kit format, assembly is straightforward and all necessary tools are included.

Browse all A4WD Kits here.

Have a potential application for the A4WD3 or want to offer new ideas, tell us in the comments below!

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post