LiDAR : Light & laser based distance sensors

FFor robots, being able to understand or navigate their environment is often critical to functioning properly. While there are plenty of sensors that allow robots to glimpse their surroundings, one category of sensors that is rapidly gaining popularity is light and laser-based (LiDAR) distance measurement/object detection. In this article, we will go over the different characteristics, the various types of sensors, their typical use cases and some of the products that we currently offer with these features.

Characteristics of distance sensors

To properly select the type of light-based distance sensor for your application you will need to detail your requirements properly (or adapt your project to fit the available/chosen sensor a bit). Here are some of the main considerations when choosing light or laser-based distance sensor:

Price

Certainly not the most important characteristic from a technical point of view but important nonetheless to complete a project, especially considering the wide range of prices. If a sensor that matches all your desired requirements is simply not within your budget, it may be better to review your design and see if other sensors can meet those new requirements. This step is common in the first draft of a project design and the best recommendation is to start small, prototype and see what is really needed. Sometimes, the better (and more expensive) sensor can be overkill or overly complex for the needs it fulfills.

Maximum distance

This is probably the most common characteristic that customers consider first. Indeed, it is quite important for many applications. But, comparing sensors based on maximum distance is not as simple as just seeing which one has the biggest number. Many sensors will typically quote their maximum range at 90% reflectivity on a flat, smooth, perpendicular surface. This is, of course, a very ideal situation. Typically, those tests are also done indoors in an environment with no interference from other light sources. Other products may give an average maximum range based on a series of tests while others will specify a maximum range at 10% reflectivity which means you can typically expect a greater maximum range in real-life applications. As you will read below, other factors can affect the maximum range too! Therefore when comparing maximum distance for this kind of sensor, be careful of the details and read the relevant sections in the datasheets provided.

Minimum distance

This value is not often listed and even less discussed, but these sensors also typically have a minimum sensing distance as well. When an object is placed closer than this distance, these sensors have various ways of reporting the distance value based on the technology used and the design choices made by the manufacturer. Some sensors will simply indicate the minimum distance if an object is too close while others will report 0. Some may actually enter an undefined state and report a completely different value. Of course, as mentioned above, it is important to check the details in the documentation and make sure to take this into account during your selection process. As a general rule of thumb, the larger the maximum range of the sensor, the larger the minimum distance will be, too, due to the characteristics of the optics required for long-range distance measurement.

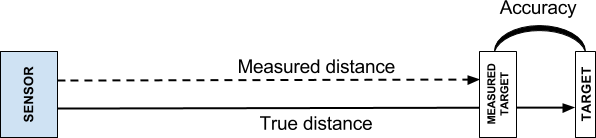

Accuracy

The accuracy typically refers to how true the measurements from the sensor are compared to the real distance that is being measured. Of course, these also vary according to multiple factors, distance being a big one. Most sensors will usually have 2 or more “ranges” of accuracy, typically a fixed one for short ranges and a secondary, variable one for longer ranges (such as a % of the distance). Just like the maximum range, these are also affected by the reflectivity of the target.

Resolution

The resolution represents how the data is reported back. Typically it will be in the same units as the accuracy. While the accuracy is quite important, the reported resolution is also critical to processing the data in a useful way. It is very common for sensors to report data in a specific unit (ex: centimeter resolution), but have an accuracy that is worse at long ranges such as ±5 cm. Therefore in such a case, you would be able to obtain a value in cm, but its accuracy must also be taken into account to properly analyze the data obtained.

Interface

The interface is also an important consideration as you will have to make sure you are able to communicate with your sensor. Many of the sensors we offer have a UART interface. Others will use USB directly, SPI, I2C or even an Ethernet connection. Make sure the interface (and protocol) used by the sensor matches an interface and capability of your system. Typically, most microcontroller boards have all of these interfaces (except maybe for Ethernet), so that tends not to be an issue. The problem often arises when you start integrating a complete (and possibly complex) robot or system and realize that you ran out of one type of interface and it happens to be one that you need for your sensor. Therefore, we recommend that you plan ahead and make sure your choice of sensor is compatible with the interfaces you have available in your project

Power requirements

Another characteristic that is often overlooked is power. Many sensors will list specifications about their running power requirements (sometimes only current and voltage requirements). But, it should be noted that many of them require more power at startup / during initialization, and often when this is not met the sensor can simply not function or responds with invalid data such as only zeroes for all measurements. It should also be noted that some sensors have specific requirements on input voltage levels, both for their power input and the I/O lines which need to be respected. This can also include advanced requirements, such as maximum voltage noise (peek-to-peek).

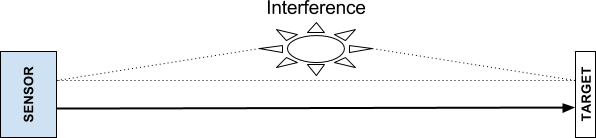

Interference immunity

Robots and other systems that need distance measurement sensors can be required to operate in a variety of environments. Therefore, it is important to ensure that your chosen sensor will perform well in the environment in which it will be operating. Alternatively, it is important to at least be aware of limitations and the impact of certain environments on your sensor. For example, many of the sensors we offer are meant for indoor use only. Using them outdoors, under direct sunlight, can greatly reduce their maximum range and accuracy or even prevent them from functioning completely (rarer, but it can happen). Most sensors that can be used both indoors and outdoors will provide two sets of specifications: one for indoor use and one for outdoor use (typically with worse values). Others may be designed for outdoor use directly and have complete shielding from sunlight (such as those that resist up-to 100000 Lux or 100 kilo-Lux, which is roughly equal to maximum direct sunlight).

Environment

Now that you know which sensors can be used in your robot’s environment, will it be OK with other challenges, such as water and dust? Many of our sensors are hobby-grade and are only meant for indoor use in a dry, dust-free environment. Some of our sturdier (and typically more professional/expensive) sensors can resist weather and dust better than the more affordable ones. If your robot will be operating in a dusty or wet environment, you will probably want to look for the IP code/rating of the sensor to determine if it meets your needs. If your setup also includes significant vibration, you may also want to see if the chosen sensor can cope and how long it can work under those conditions.

Sensor weight & size

Of course, if the sensor meets all your other requirements, it would be important to make sure that it actually fits inside your robot or system and also does not overload it due to excess weight! Most of our sensors are solid-state devices that are pretty light (plastic as opposed to metal casing), so weight is typically not an issue for most stationary and mobile applications. Of course, if you intend to use the sensor in a low power application, near the end effector of a robotic limb (ex: robotic arm) or on a flying robot (such as quadcopters), weight will matter a lot more.

Refresh/measurement rate

This is not typically a big issue with single/multi-beam sensors but does often come up with rotating distance measurement sensors. This characteristic translates into two potential issues: 1) will the sensor’s output be fast enough for my application and 2) can my system process the amount of data it will receive?. On the first point, it will be important to check the sensor’s documentation concerning the refresh rate and its relationship to the maximum range, accuracy and data output. If it is a rotating sensor, the angular resolution will also be important to determine how many measurements your system will be receiving from the sensor. Concerning the second point, it will be important to ensure your system can process the amount of data the sensor will provide. In some cases (such as with single beam sensors), you can simply not read or ignore data when it is not needed. In cases where you use a rotating sensor, that may be harder to do without losing data points (or adding complexity to the processing of this data).

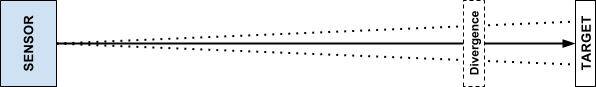

Beam size/shape

In some cases, you may be worried about the minimum sized object the sensor can detect. This becomes especially important at longer ranges, where a beam may simply have diverged too much to detect smaller objects. By checking the documentation you should be able to find information about the divergence of the beam as a % over distance or in milliradian (or mil and mrad). Using these numbers and some basic trigonometry you should be able to quickly figure out how large a beam will be at a certain range.

Single beam sensors

These sensors produce only one beam and are typically used to detect distances to large objects such as walls, floors, ceilings since the beam is very thin (compared to other technologies such as ultrasonic sensors). That being said, you can generally separate the beams in two categories: highly collimated beams (such as those used in a laser pointer) and LED & pulsed laser diode beams. The highly collimated beams will tend to stay very small throughout the entire range whereas LED & pulsed laser diode beams will tend to diverge over large distances, similar to a flashlight beam. Here are some products of this type and their various ranges:

Proximity (<= 6 m)

For such very short ranges, it is usually more practical and cost-effective to use simple infrared (IR) reflection instead of more complex/costly LIDAR systems. You can find many such options in our Infrared Range Finders category. Most of these sensors measure distances in the centimeter as opposed to meter range and tend to vary from a few millimeters to about 150 cm. Parallax 15-122cm Laser Rangefinder

Short range (<= 10 m)

Medium range (<= 20 m)

- Benewake TFMINI Micro LIDAR Module (12 m)

- TeraRanger One ToF Rangefinder Type A (Spider) (14 m)

- TeraRanger One ToF Rangefinder Type B (Frame) (14 m)

- TeraRanger Duo ToF Rangerfinder with Sonar Sensor (14 m)

- TeraRanger Inspection Drone Kit w/ 1 Type B Sensor (14 m)

- TeraRanger Inspection Drone Kit w/ 3 Type B Sensors (14 m)

- LeddarTech LeddarOne Optical Rangefinder (RS-485) (15 m)

- LeddarTech LeddarOne Optical Rangefinder (3.3V UART) (15 m)

Long range (> 20 m)

- Benewake TF02 LIDAR LED Rangefinder IP65 (22 m)

- ILM Laser Rangefinder (35 m)

- LIDAR-Lite 3 Laser Rangefinder (40 m)

- LIDAR-Lite 3 Laser Rangefinder High Performance (40 m)

- SF30-B Laser Rangefinder (50 m)

- SF30-C Laser Rangefinder (100 m)

- ILM Laser Rangefinder (150 m)

Multi-beam sensors

These distance sensors produce multiple detection beams, usually simultaneously and are better suited for object and collision avoidance. These can vary in range from about a meter (TeraRanger Multiflex 8 Sensor Kit) to dozens of meters (LeddarTech Leddar M16 Sensing Module (10° Beam)). You can view the full category of multi-beam sensors here. Potential uses include autonomous robots moving around unknown environments or environments with moving obstacles (people, other robots, etc.) such as an office or a warehouse.

Rotational sensor

In this case, the sensor typically produces only one beam as the device is rotated while the measurements are taken. They are typically used for SLAM and object detection & avoidance. Because of the high rate of data produced, these are usually best used with a Single Board Computer (SBC), which can better handle processing the data than simple microcontrollers. The complete category of rotational distance sensors can be found here. Here are some examples of the various types of rotational distance sensors you may encounter:

Range data only

In these cases, the sensor only provides raw data (distance measurement) and you will have to program your controller to process it. This can be quite useful for SLAM as this is all you really need (sensor-wise) for creating a basic map of its environment. Here a few popular products that can be used to do this:

RPLidar A1M8 - 360 Degree Laser Scanner Development Kit

RPLIDAR A2 360° Laser Scanner

RPLIDAR A2M6 360° Laser Scanner

Hokuyo URG-04LX-UG01 Scanning Laser Rangefinder

Hokuyo URG-04LX Scanning Laser Rangefinder

Hokuyo UBG-04LX-F01 (Rapid URG) Scanning Laser Rangefinder

On board processing

These more advanced rotational sensors will not only scan an environment with a rotating beam but also include a certain amount of signal processing to obtain useful information directly out of the data, such as object detection, zones of detection, etc. Here are some examples of sensors that do this type of processing:

Hokuyo PBS-03JN Scanning Infrared LED Obstacle Detection Sensor

Hokuyo UST-10LN Scanning Laser Obstacle Detection Sensor

Hokuyo UST-20LN Scanning Laser Obstacle Detection Sensor

Summary

Light and laser-based sensors are certainly increasingly popular in recent years and can offer robots a better way to understand their environment. With more such options now available for hobbyists at affordable prices, it is certainly worth considering for do-it-yourself (DIY) robots/projects. Have you used such sensors? Which one is your favorite? What do you use them for? Let us know in the comments!

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post