stepdirection.c (4219Bytes)

rename_to_makefile_without_extension.txt (10019Bytes)

cnc1.jpg (102720Bytes)

cnc2.jpg (118695Bytes)

IMG_0064.jpg (91642Bytes)

cnc4.jpg (72573Bytes)

cnc5.jpg (29314Bytes)

cnc6.jpg (45116Bytes)

cnc7.jpg (47402Bytes)

cnc8.jpg (42451Bytes)

Here you can find Version 2.0:

https://www.robotshop.com/letsmakerobots/node/19239

Inspired from Tinheads "Valkyrie 2.1" is started building my own CNC last weekend. Until now the X and the Y axis are ready and i also got one Motor running.

Differences to Tinheads CNC:

- drawer guide rails with ballbearings

- the table is moving and not the Y-axis

- Sanguino instead of Arduino

The Motors i'm using are from an old Tektronix Plotter. (They are nearly two years older than me... Produced Feb. 1978) They have 1.8° per step so i'm going to have a wonderfull resolution...

Update:

This evening i changed the leadscrew a littlebit and now the X-axis works much better. So i have now 2/3 of my cnc working ;-) It also painted an eagle file ;-) And makes funny music while doing this ;-)

I also found out that the G01 F Statement can set the feedrate higher than max. Feedrate. Is there a good reason for this? If not i'm gonna change this in the sourcecode. Editing the gcode by hand is a lot work ;-)

Tommorrow i will start assembling th z-axis.

Next Update:

It's done!!! at least for now ;-)

YAU (Yet another Update):

Yesterday evening i tried to mill a PCB. After about 1 hour good work it started loosing steps. First on the Z-axis and then on X too. I think i will have to increase the Voltage. 'til now I'm using 5V and the motors stay cool. So there is ptential for more torque i hope. I'm driving the Motors in fullstep mode with 2 Coils powered a time. I think this is the strongest mode they can be driven...

Update: New Video

Update 14. Feb. 2010:

Today I switched over to EMC2 to control the Mill. For this I had to change the Stepperdriver Firmware a littlebit so that it will accept step/direction signals. I attached the sourcecode and the makefile to this page.

Result: its working really good with EMC2. I can drive all axis at double speed because EMC accelerates the Steppers so they don't loose steps.

Update 19. Feb. 2010

My dremel clone broke down tonight - still running but a 1mm mill-bit makes about 2mm line. You can fell that theres a little play on the bit-clamp. So i'm going to buy a new one. But now i have to make a decision dremel 300 or proxxon FBS240E or Proxxon IB/E

Dremel:

+ up to 40.000 RPM

+ cheap 50€

+ 125W

- they don't say anything about accuracy

- hard to mount

Proxxon FBS240E:

- only 20.000 RPM

+- a littlebit more expensive 60€

- 100W

+ collet-chuck (Spannfutter)

+ seems to be better mountable

- they don't say anything about accuracy

Proxxon IB/E:

- expensive 90€

- 100 W

- only 20.000 RPM

+ is professional mountable

+ has a high accuracy 3/100mm

I hope they have them all available in the hardwarestore tomorrow so that i can get hands on them. If anybody reading here has a quick suggestion, please post....

Update 26. Feb. 2010:

It's a Proxxon! A FBS240/E. And it seems to work quite good! But the axis speed of my mill is much to low (120 mm/min). So I decided that i need a new stepper-controller. This time with integrated current-limiting. I took a look at a lot of available circuits on the net but then I've found this one:

http://www.mechapro.de/catalog/stepper-motor-power-stages-c22/3d-step-pcb-for-3-channel-stepper-motor-board-p33/?osCsid=c58roccm0mh2b22qnuo1ogpkh0

It's just 20 Euros (PCB) and gives me some important new features: sleep and boost. For 20 Euro i cannot make my own pcbs... (time, material, failures...) I will try 12V tomorrow. Lets see what speed i will get out of it ;-)

Greets

Daniel

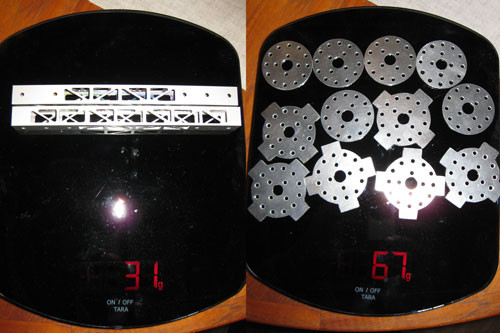

Update 1.3.2010:

I installed the new stepperdriver and it was a great success! Had a little trouble with some old atx-powersupplies but now it works!

Old speed was 2mm/sec and acceleration of 1.5 mm/sec^2 on all axis

New speed:

X: 6mm/sec 10mm/sec^2

Y: 10mm/sec 13mm/sec^2

Z: 15mm/sec 20mm/sec^2

All 12V, X and Y running at 1A each, Z at 2A.

Things to change:

- find a cheap bigger powersupply 30-40V 4-5A

- exchange Motors on X and Z (the motor on Z is the strongest!!!)

- change the 8mm thread-rod on x axis to a 12mm one (to get rid of the wobbling problem.....)

Update 9.3.2010:

The Proxxon ist also a piece of....

Tonight it broke down. A 1mm tool makes an about 2mm hole... I will try to get my money back tomorrow. Instead of the proxxon i ordered a Kress 800FME. With this I hope I will have enough power and longtime qualitiy. The give 10 Years warranty and its a professional tool.

Not so good:

Last week milled a really good holder for the proxxon. But this is unusable for me now, because the kress spindel has an 43mm mount...

Update 16.3.2010:

The Kress spindle cuts everything like butter ;-) Now i can do some Aluminium too:

https://www.youtube.com/watch?v=KnkxrvKsOw4

(only x and y-axis assembled til now)

(only x and y-axis assembled til now)