oh good lord i just realise i am using cm in the force calculation and about to get a 100kg torque thank god i was wrong. Also the calculation that i am doing here should be the stall torque no? which mean my servo can hold it but cannot move itself.

It’s really up to you to interpret the torque and select accordingly. Normally dynamic torque is 1/4 static, so the arm will be able to hold itself straight outward, but won’t have enough torque to move up (it can move down though). If you want it to move up from fully extended and maximum load, you’ll need to multiply the value you get by around 4 (napkin math).

Hello sir,

As u have said that it does not calculate Torque for acceleration but only for against gravity and with a safety factor of 2 . So do i need to multiply the value (eg Motor 1Torque) by 2 to get approximate value for total Torque or its already multiplied by 2 and that’s the final Torque.

@Vaibhav8181 Welcome to the RobotShop Community. I don’t think the output values have been altered at all in the calculations, so they are just providing the “steady state” torque (i.e. static / not moving). When you look for a motor, the manufacturer often provides the “stall” torque which is never intended to be reached (preventing the motor from rotating burns it), and only more expensive motors tend to include the torque at max efficiency and max power. The “torque at max power” value provided by the motor manufacturer would be what would correspond to the output of the “Torque Calculator” without a multiplication value of 2. However since many motor descriptions / specs (especially for RC servo motors) don’t have that, the comfortable “dynamic” torque (i.e. under motion) provided by many DC motors is only around 25% of their “static” torque, though in many cases it can be pushed up to 50% for very brief periods, which is why the “napkin math” is to multiply the static torque value by at least 2.

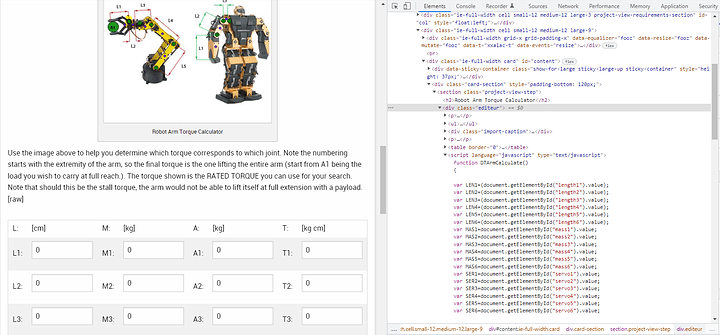

If you’re curious about the equations used in the code, you can press F12 in most browsers, select the section with the input values and expand until you get to this section labeled “editeur”:

Thankyou sir. Btw I going to use stepper motors.

Stepper motors are quite different than brushed / brushless DC motors - their control method is very different and they offer higher torque at lower speeds. Note too that the step mode (full step , half step etc.) also affects the torque, as does the input voltage. Absolutely read a lot about stepper motor operation.

hey, I used your calculator and got a required torque of 612kg-cm at the base, so according to that if you have any knowledge in this field can you suggest one good stepper motor for this torque.

I know using gears will increase the torque output of the motor but I could only find a 20kg-cm stepper motor, so if you could share any details of a motor it would help me a lot. thanks

@robosahith Welcome to the RobotShop Community. If you can only find a 20Kg-cm stepper, you’d need at least a 30:1 (if not more) gearbox to get the ~600Kg-cm needed. Is 20Kg-cm the MAX torque which the stepper can provide? If so, that’s enough to maintain the arm at full reach, but not enough to lift it.