I was looking at the plans that myblack60impala had posted, https://www.robotshop.com/letsmakerobots/dr-who-k9-plans, and remembering how cool I thought that Maxhirez's K9 build, https://www.robotshop.com/letsmakerobots/node/39295, is! And the next thing I know I am looking for some material to use! As it turns out, I have a bunch of 1/16" acrylic scraps lying about.

I decided that I was not going to pursue a build as ambitious as the one that Max had made. So I settled on a 1/4th scale K9. My plan is to use either a Pro Mini or a Propeller as the brains. I have not decided which I will use as yet, the final decision may be made for me because of the inherent spacial limitations of the build. I will include a laser weapon feature in the head, every K9 must have that, and the usual compliment of sensors and such. Not certain what features I will pusue beyond the basic obstacle avoidance and terrain edge detection, much will depend upon the amount of space available.

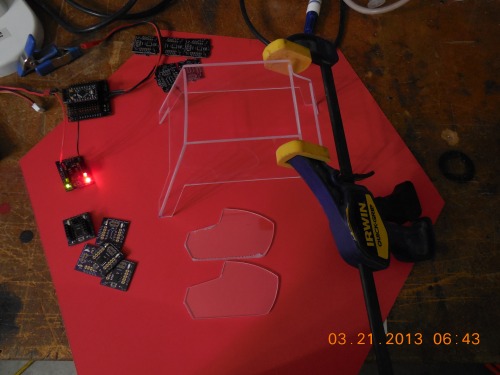

I started by cutting out the main body parts and the sides of the head...

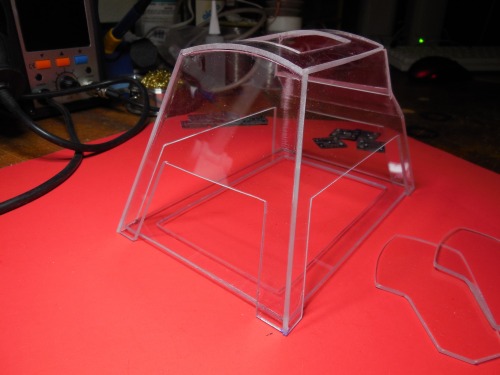

I then began assembly of the body. One of the problems that I encountered was that the acrylic glue that I am using is very old and probably long past it's shelf life. Instead of being the consistancy of water, it was more like a gelatinous goo! But, having been unsuccessful at locating a local source for fresh glue I decided to press on! It does not provide a very strong bond, but it is all that I have to wok with.

The top panel of the body has an arched shape. I first cut the panel to size, plus a little extra for fitting, and cut out the hole for the control panel. I then shaped the acrylic panel by heating it to 250 degrees F, for 60 seconds or so, and then placing the still warm/malleable panel in place. The panel easily bent to follow the contour of the body ends.

To heat the panel I used a $20.00 toaster oven that I recently purchased to use as a reflow oven in my garage. It works great for reflowing SMD boards. It heats up quick, does an excellent job (at least on the small boards that I work with) and I can flow multiple boards at one time. I recently flowed a batch of nine boards at once and it took less than 3 minutes. But, that is a topic for another blog!

I don't have any pictures of shaping the panel. It was just not possible to take pictures during the process because of the limited work time of the heated acrylic. But the oven worked out great for this too!

This is a companion discussion topic for the original entry at https://community.robotshop.com/robots/show/acrylic-mini-k9