Regulating Cobots: How Human-Robot Collaboration Impacts Workplace Safety Standards

Over the last couple of decades, there have been significant advances in industrial equipment. Perhaps the most interesting of these is the growing introduction of collaborative robots (cobots), many of which are supported by artificial intelligence (AI). Certainly, these tools can offer a range of advantages, but it’s important to recognize that they pose risks, too.

In most cases, workers in high-risk fields are protected by federal safety regulators, such as the Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety & Health (NIOSH), among others. These agencies are tasked with setting safety standards, ensuring compliance by performing inspections, and enforcing violations. However, cobots can present challenges when regulators and their guidelines aren’t fully up-to-date on current technology.

As a result, it’s important to gain a better understanding of how human-robot collaboration impacts workplace safety standards. This enables businesses to make more robust safety adjustments and work with regulators to address the issue.

Understanding Cobots

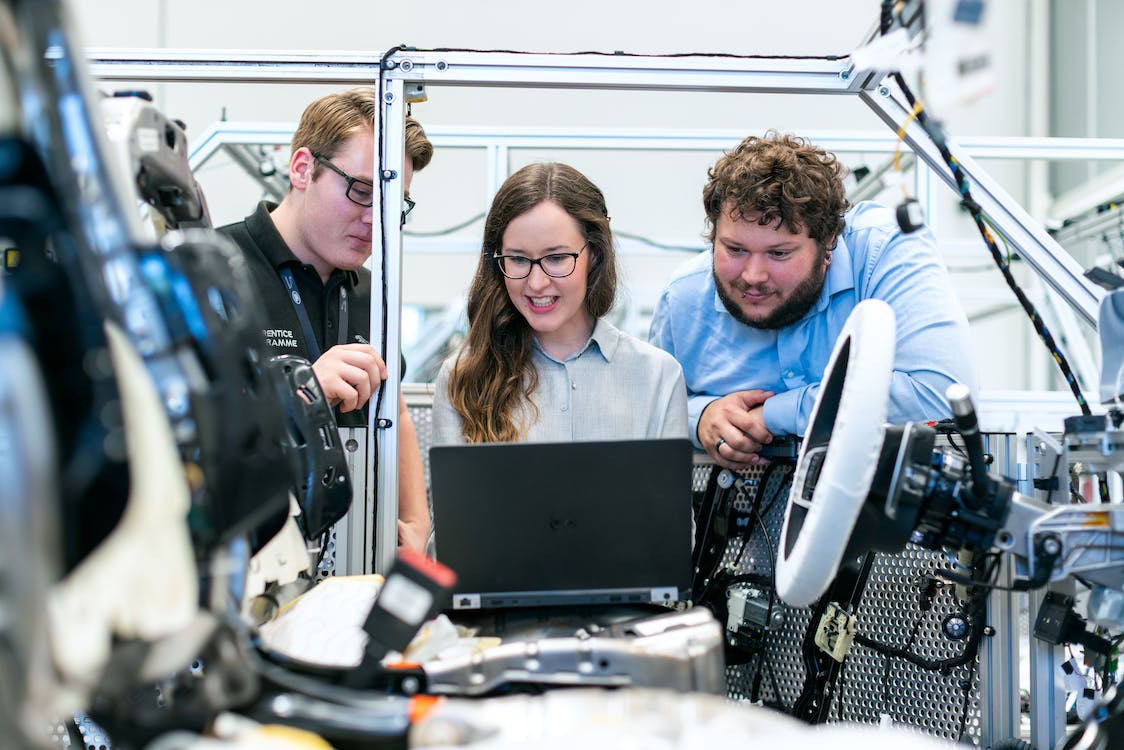

By definition, cobots are robots that collaborate with human workers. This isn’t quite the same as the forms of automation that effectively replace what workers are doing. Rather, these machines manually — and in some ways, intellectually — support the skills workers bring to their jobs.

These tools are present in a range of industries. Certainly, the automotive industry is the highest adopter of cobots in factories and plants, however, they are also emerging in areas such as medicine to assist in surgeries, minimizing exposure to hazardous materials in waste management, and supporting manual labor in construction. This is just the tip of the iceberg, though. As cobots become more affordable and capable of a wider range of tasks, more industries are adopting them.

Certainly, this offers significant benefits to businesses and workers alike. In many ways, enabling cobots to take on the more physical or potentially harmful tasks human professionals would usually handle reduces unnecessary hazards.

However, this also presents significant challenges. Many cobots themselves constitute forms of heavy machinery, which can make close interactions with humans potentially hazardous. Also, without effective control safeguards, cobots’ mishandling of hazardous items could put workers and the public at risk.

Adjusting Risk Assessments

Risk assessments are an important part of workplace safety standards in any business. Indeed, regular hazard evaluation is a legal requirement to ensure the ongoing protection of workers and the general public. However, the growing integration of cobots can make risk assessments more complex for businesses and regulators alike. Therefore, assessment processes need to be adjusted to consider this.

Organizations, such as OSHA, have already started to provide guidance related to robotic risks that can help guide businesses in their assessments. However, these tend to be limited in their scope. Certainly, given the rapid pace of development and increasing accessibility of these tools, it’s not difficult to overlook key areas for assessment. Therefore, businesses and industries must develop practices that are relevant to the context in which they use such tools.

This begins with detailing all aspects of cobot functions within an organization. Assessments must include the physical characteristics of cobots, what they’re programmed to do, and how that programming is achieved, alongside the specifics of their interactions with human coworkers. Even elements such as speed of cobot operations, payload capacities, and levels of force exerted can help assessors establish the potential hazards and the damage accidents might cause.

It’s important to involve the staff that work alongside these cobots in risk assessment processes, too. This isn’t just because their actions can contribute to the risks or because they may be subjected to hazards. These workers — from manual laborers to programmers — are also likely to have deeper insights into their interactions with cobots. Not to mention that they can be vital in establishing protective solutions.

Wherever possible, sharing this information with regulatory bodies can help create a more robust industrial landscape. After all, practical insights into how the risks are changing can influence more effective and relevant regulation.

Adapting Company Policies

Risk assessments empower businesses to make the most relevant organizational changes. Robotics and AI are likely to impact safety protocols in ways that best leverage the benefits and safeguard against hazards. For instance, organizations could utilize AI analytics to perform predictive maintenance on cobots to ensure safe functions. Alongside the more obvious policies to minimize accidents due to errors, there may also be a need to arrange policies that address issues caused by unexpected AI biases.

Because internal policies tend to set expectations for operations and bridge gaps in regulation, it’s important to start adjusting them as soon as possible. Some of the areas for consideration include:

Employee education and training

By definition, cobots require human interactions to be effective tools. Therefore, it’s vital to ensure employees receive education on safe interactions with cobots on a regular basis. Policies should outline the forms of training employees who interact with specific types of cobots require, what certifications meet the minimum standards for continued employment, and how updates are to be delivered.

Organizational oversight and safety measures

Organizational documentation should clarify the specific types of tasks each type of cobot is cleared for use and specify that there is no authorization for use beyond this. These policies should also provide information on which staff members are responsible for reviewing the safety components for each cobot and with what frequency. Importantly, there should be clarity on the procedures staff must follow to report all potential safety incidents, alongside who should respond to these and how.

Conclusion

Cobots offer various advantages but they also present unique risks. Federal safety regulators play a role in setting standards and ensuring compliance, but they face challenges in keeping up with technological evolution. It is, therefore, essential for businesses and industries to gain a better understanding of human-robot collaboration and its impact on safety standards. Moreover, adjusting risk assessments and adapting company policies helps to mitigate potential hazards and maximize the benefits of cobots.

In addition, it’s worth businesses, industries, and regulators alike seeking insights from cobot developers. These professionals are likely to have insights not only into what the current risks are but also what the hazards of emerging tools may be. This could help stakeholders devise solutions and regulations in advance, which minimizes gaps in employee safety.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post