How Are Robotics Helping to Automate Hydroponic Systems?

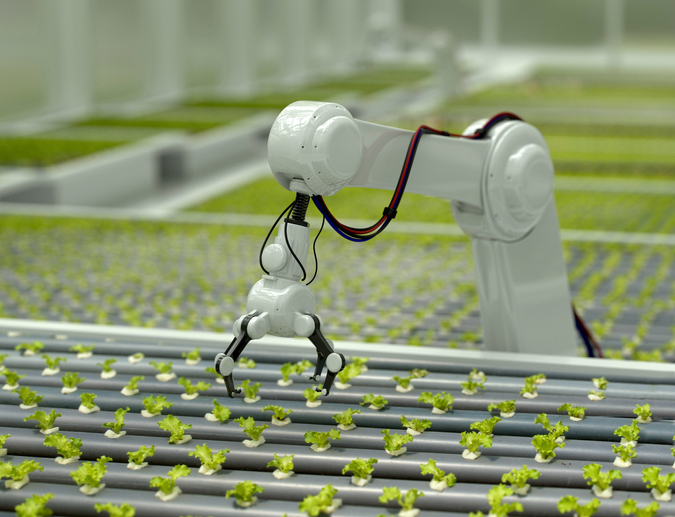

Imagine hundreds of glistening leafy greens all nestled under one roof. Their roots dangle in nutrient-rich water. Slowly, a robotic arm lifts their tray into the air, monitoring their health and diagnosing treatment. These amazing automated hydroponic systems are no mere dream but an exciting innovation being utilized in the agriculture sector today.

For millennia, humanity tested new methods of agrarian ways of life. Yielding healthier crops to reach more people is always a need. Hydroponics was even used in the ancient world, allegedly in the hanging gardens of Babylon.

How do hydroponics sensors differ from traditional farming? Here’s an in-depth look at the future of agriculture and what innovations are being seen today.

What Are Automated Hydroponic Systems?

Hydroponics is the method of cultivating crops in a controlled environment. This is often utilized indoors so water and air are monitored. Hydroponics does not use soil, either. Growers use water for their plants to rest on, soaking up nutrients through their roots.

One hydroponic trend is the cultivation of leafy greens like lettuce or basil. These popular and versatile vegetables are the basis for a healthy diet. Some fruits are also well-acclimated to water-based growing, such as watermelons.

Incredibly, even hydroponic coffee is a possibility. Climate change is flooding the low valleys where coffee beans are grown, halting production. However, beans can prosper and thrive in these controlled, smaller environments.

Sustainably Saving Lives

Hydroponics is the key to a few critical issues in the food industry. For one, a growing population demands more food. The UN expects the world population to reach 9.7 billion by 2050. Helping food get to hungry people and reducing waste is the main concern.

The food market is currently decentralized, and fruit must be shipped about 2,000 miles on average to reach its destination. Only a small portion of U.S. counties have farms, so freshness and flavor are lost in the travel time.

There is also a large labor shortage affecting agrarians. Younger people are not taking up the mantle of agricultural professionals, resulting in billions of dollars lost.

Robotics in the Greenhouse

Hydroponics are incredible in their own right, but a fully automated hydroponic system offers an ever brighter future of fresher, healthier food. Smart sensors and powerful lifting features can care for these plants with stark intelligence. Explore the wonders of these incredible inventions and how they ensure the crunchiest and tastiest greens.

1. Hydroponics Sensors

Robotics only occasionally look like lumbering metal giants. Sometimes they are smart sensing technology or part of a building’s infrastructure. Smart greenhouses are the controlled element of the hydroponic system. They can monitor and adjust unacceptable levels of:

- Temperature

- Humidity

- Lighting (often UV rays to simulate sunlight or blinds to harness the sun’s power)

- Ventilation

- CO2 levels

- Nutrient levels in the water or plants

- Mold or other plant diseases

These adjustments and findings can all be stored on one online portal, keeping growers updated and able to make their own changes.

However, hydroponic greenhouses are reimagining the farm with less space and waste. Plants are packed together in greenhouses and can be used year-round in many regions, centralizing food production for people across the country.

Hydroponics sensors are all industrial quality and can be submerged in the water tray. They provide a clear diagnosis and care for the environment within the greenhouse, helping plants prosper.

2. Iron Ox Robotics

Iron Ox is a startup leading the robot revolution in greenhouses. It noticed how inefficient hydroponic greenhouses could be, despite their effort to reduce waste.

The company began with an automated hydroponic system with nutrient-rich water and a grid for each plant to rest inside. However, it also employed smart sensing and automated robotics technology to care for the plants and assess their health. These innovations promise a sustainable food future.

3. Grover

Grover, one of Iron Ox’s robots, acts like a taxi service. It is self-driving, transporting seedlings and sprouts to different areas around the greenhouse. The stereo cameras equipped on its wrist can sense where to pick the tray up. Grover builds 3D images of plants to understand the weight and density of each load.

It also lifts with custom grippers perfect for the size of Iron Ox’s trays. Hydroponics sensors in the arm can monitor the balance of the tray to ensure all plants are transported safely.

4. Ada

Ada is a robot employed at Iron Ox that also lifts trays of seedlings. However, instead of only carting them around, Ada inspects the batch of crops. Hydroponics sensors in Ada’s limbs check for nitrogen, potassium, phosphorus and acidity levels in the selected plants.

After recording these levels, it can understand what a specific plant needs to grow. If nitrogen levels are low, Ada diagnoses the problem and alerts the system to release different chemicals.

5. Angus

Angus is another Iron Ox creation that surveys the greenhouse as a whole. Like the others, it has a stereo camera to create 3D images. Angus diagnoses issues in growth by looking for wilted leaves and signs of mildew or pests.

It sends findings to the cloud-based brain, where other robots can send corrective action to the plants in question. Like Ada, Angus monitors plant health, only on a macro level.

The Future of Robotic Hydroponic Systems

The future for automated hydroponic systems is bright. Reducing water, electricity and waste in state-of-the-art monitoring systems helps people find the best food in their grocery stores. The speed and efficiency of food output will continue to grow as innovations do,

The robot revolution is here and will help produce better food for people worldwide well into the future. More innovations are expected to pave the way for continued growth in this industry.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post