Exciting Advances in Industrial Automation

Industrial automation isn't a new concept, but we've come a long way since Henry Ford first introduced his automotive assembly line in 1913. The last two decades have seen extensive technological growth. Let's take a closer look at some of the most exciting advances in industrial automation.

Manufacturing

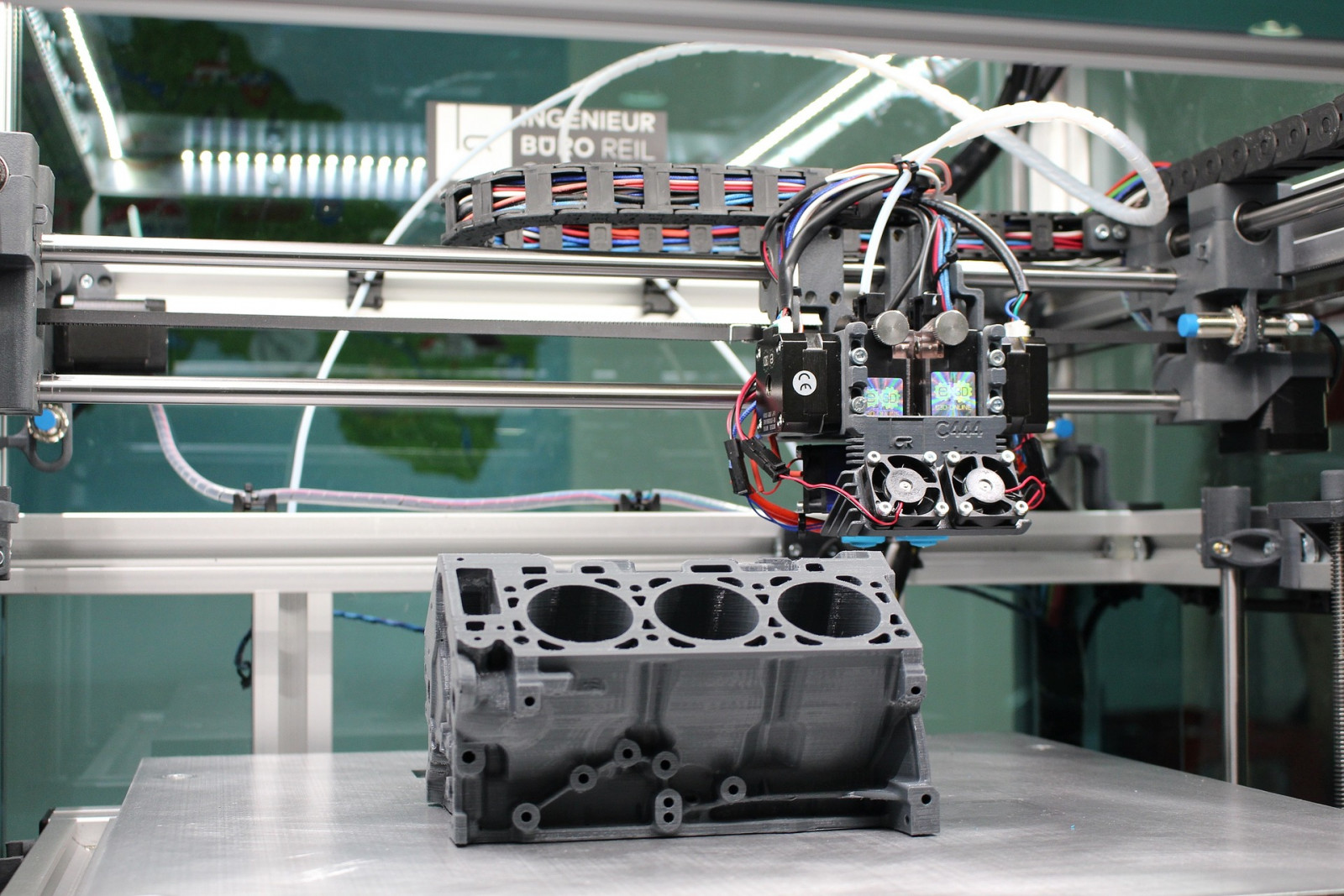

3D printing was once the purview of hobbyists and crafters, but it is quickly finding its niche in the manufacturing industry. The use of 3D printing is the most significant advance in manufacturing in recent years, especially the use of these printers for the creation of finished parts.

Rather than creating a new manufacturing process for each new piece, 3D printing allows manufacturers to print complex and customizable products on demand. In theory, it could even be used in the field by members of the military to print replacement parts on the go instead of waiting for a shipment of replacements from their base. $13.2 billion was earmarked for 3D printing technology in the 2018 military budget. They’ve even designed and test-fired a grenade launcher – named RAMBO for rapid additively manufactured ballistics ordnance – that's completely 3D printed. Even the grenades are printed on demand.

Distribution

Industrial automation has already started to upset the distribution industry. Amazon recently purchased Kiva Systems, Inc, a robotics startup, and used their facilities to create a fleet of autonomous robots for their distribution centers. To date, more than 45,000 distribution robots inhabit their facilities across the country, filling orders and stocking shelves.

These robots aren't perfect. Experts estimate that it may be a decade or more before the artificial intelligence of robots can replace humans completely in distribution, but the industry is moving in that direction.

Retail

Perhaps the biggest impact from 3D printing will be felt in the retail industry. It’s being described as a game changer, and gives retailers the ability to create customized projects faster and at lower cost than traditional manufacturing techniques. Even fields that might not normally rely on new technology – like shoe design – can benefit from 3D printing. Onel company is offering 3D printed shoes that are based on scans of the customer’s foot to provide the perfect fit and optimum comfort.

It isn’t all sunshine and rainbows for the retail industry when it comes to industrial automation though. Experts estimate that between 6 and 7.5 million jobs in this sector will be replaced with automation in the future. Not only will it negatively impact the employees who are at risk of losing their jobs in favor of automation, it could damage local economies as these workers lose their buying power.

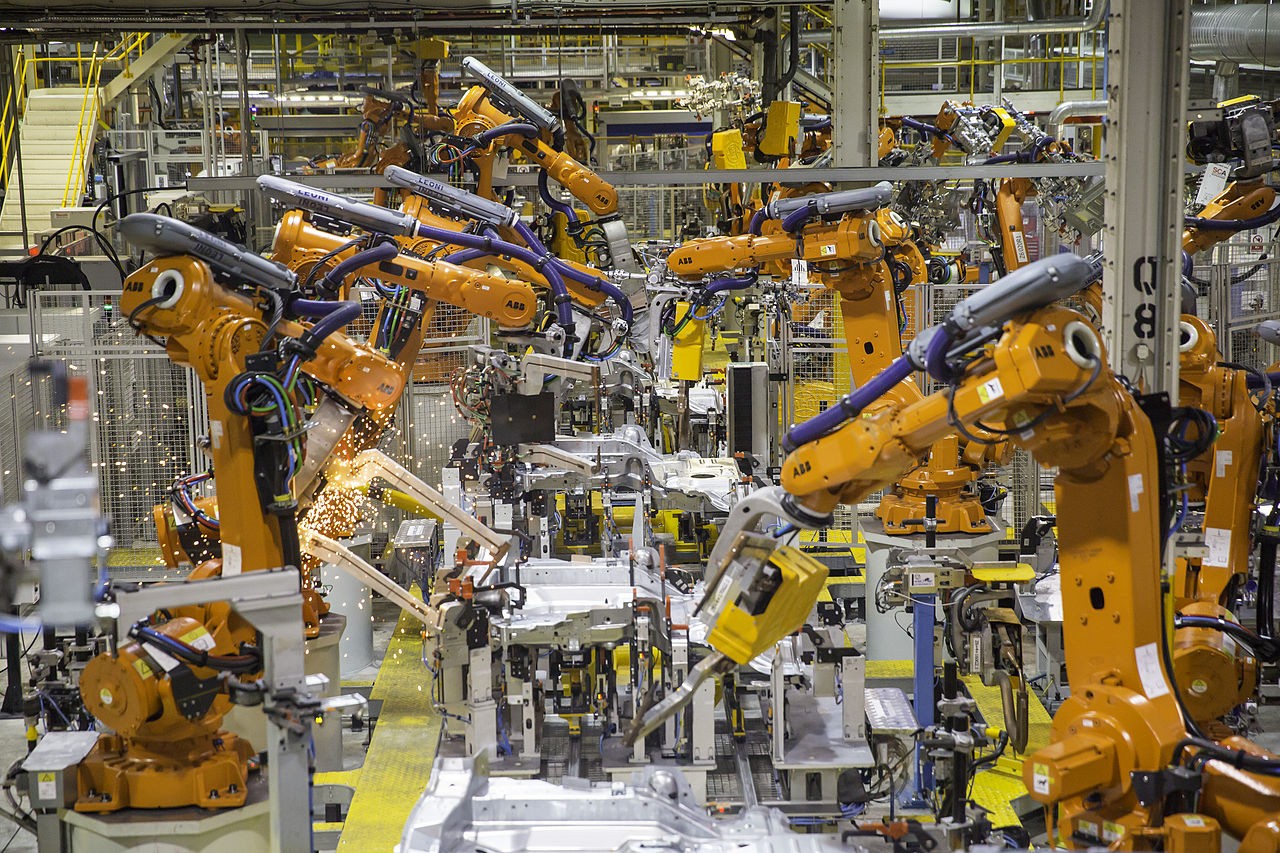

Metal Fabrication

Metal fabrication is a growing field, but there are fewer jobs available in this industry than ever, primarily due to the adoption of automation in this sector. An 80,000 sq ft factory that would typically employ more than 100 human workers can function efficiently with less than half that number.

For companies that operate 24 hours a day, like those in the oil and gas industry, metal fabrication is an essential part of the process. Automation allows for the creation of custom-fitted walkways, railings and other pieces that keep the human workers safe in an otherwise dangerous industry. Instead of having to modify generic fragments before they can be installed, an automated metal fabrication plant can customize a stairwell or railing with a few keystrokes.

Construction

Construction automation is a relatively new endeavor, but new technologies are making an appearance and changing the field. 3D printing, for example, is finding a niche with printers that can print an entire concrete building, one layer at a time, in 24 hours. These printers use the same principles as the small desktop printers that extrude plastic, only on a larger scale. In theory, these machines could be programmed and turned on and could build an entire project with minimal human interaction.

This advance in industrial automation could make building a home more affordable and accessible for many individuals. It will also reduce the amount of material needed to construct a building and reduce jobsite waste. For consumers that prefer a classic brick façade, there is the Hadrian X – a portable robotic arm that can lay up to 1,000 bricks an hour. It can cut its own bricks, lay mortar, and assemble a brick house in a fraction of the time that it takes human bricklayers.

Supply Chain

Cold supply chains are always challenging to manage. Opening and closing the doors to let human workers enter and exit the climate-controlled warehouses make it harder to maintain the interior temperature and could put the temperature-controlled products at risk.

Utilizing automation in cold supply chains obliterates this challenge. Instead of needing human workers to pick orders and fill pallets, automation can complete all of this work. If the hardware is paired with a process chiller to keep its ambient heat from damaging the stored products, human workers can be removed from the equation.

Future of Automation

We are entering the age of automation, and these changes are only serving to advance the industries they touch. Technology will continue to move forward, and it is up to existing companies to adapt to these changes or be left behind. Supply chains, construction companies and the military will likely benefit the most from these advances, while the retail industry may feel some of the negative repercussions. We’ve entered the 4th Industrial Revolution, and the push toward industrial automation will keep us moving forward into the future.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post