California Burger Joint Ushers in the “McRobot” Era

Time to make a field trip to Los Gatos, California, to its new fast-food restaurant. BurgerBots is the world’s most recent robotic innovation in the sector, and machines run the show. It will satisfy everyone’s cravings by handcrafting delicious patties from metal hands. Discover how the fast-food robot changes the scene and if it is worth the hype.

The BurgerBots Burger Experience

For $18, customers can get an all-beef patty with special sauce and other fixings. It sits on a tray with a QR code that details what burger it will hold. The advertising touts surgical precision, but the restaurant still has a human touch. The business employs people to handle registers and deliver meals.

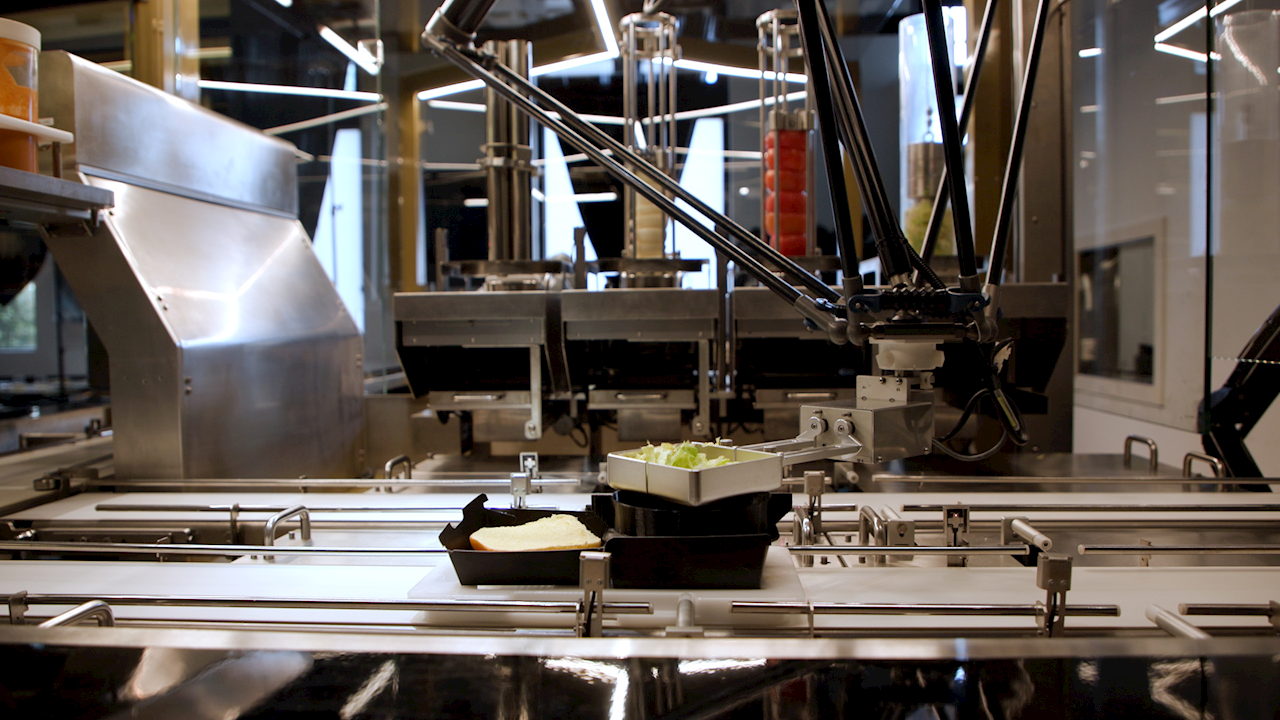

The robots, made by ABB Robotics, are a type of cobot. The IRB 360 FlexPickers and YuMi models are responsible for grinding meat, flipping burgers and sending ingredients down a conveyor for assembly. Everything happens in a shocking 27 seconds. They can even accommodate adjustments to the meal, making them easily customizable for every customer.

Microcontrollers are at the heart of every robot, empowering its memory, processing power and peripherals. They also enable real-time control, which allows a fast-food robot to assemble a burger with near-perfect accuracy. Its flexible motor skills and safety mechanisms are due to these advanced pieces of tech, which make it possible for cobots to exist.

The Job-Stealing Debate

The restaurant opened in the heart of Silicon Valley — a hub of tech’s greatest minds. It was the perfect location for testing the public’s reception to incorporating robots into food service.

It is indisputable that these robots could take jobs away from humans. Many places already use food-delivery robots to roll meals and drinks to tables. However, one could argue that the BurgerBots machines didn’t because the restaurant wouldn’t have people in these positions anyway.

The company’s concept never included humans to fill the roles. So, the shop’s design simply doesn’t and will never have an opening for a burger flipper. Customer attitudes could change if these robots sneak into other popular franchises, like McDonald’s or Burger King.

ABB thought about these concerns and executed a survey of 1,250 hospitality workers. Around 67% wanted to delegate gross, repetitive and dangerous tasks to robots. The majority also wanted them to help them make their jobs simpler.

The Other Implications of the Fast-Food Robot

The BurgerBots revolution will spark many contentious and productive conversations about cobots in food service.

Reduced Turnover

Many restaurants could see these assembly robots becoming a type of security. The jobs they accomplish have high turnover rates with human workers, and eateries protect themselves from these losses by leveraging machinery. They can let people do more high-value, meaningful tasks, which leads to a greater quality of life in the workplace.

Servers can spend more time with customers and develop connections that lead to a more authentic experience. The robots will supplement the workforce. Fast food suffers from labor shortages, and cobots will fill the gaps.

Improved Hygiene

Using robots with high cleanliness standards and eliminating human error is a recipe for consistency. With robots behind the assembly, there are fewer contamination risks. Imagine never seeing a rogue hair or piece of plastic in food ever again. Restaurants will comply more easily with legislation and quality frameworks. BurgerBots could set the precedent for food quality and safety.

High-Speed Output

Quick-service restaurants and fast-food joints must maintain a solid pace to keep customers happy. With a 27-second turnaround, people can hardly beat this level of efficiency. It only leads to happier customers, which makes the employees’ shifts more enjoyable. They have to manage fewer complaints and endure fewer frustrations from disgruntled clients.

Better Inventory Management

The robots are connected to inventory databases. Every time it assembles an order, it tabulates what ingredients went into that dish. The real-time data oversight keeps stock visibility more accurate and up to date. Staff will always know when they are low on condiments or fresh vegetables because the robots send this information immediately to programs.

Reduced Human Error

Robots will make fewer mistakes when it comes to cleanliness. They will also have a higher chance of making orders right every time. A robot can’t forget an order like a human could if they were busy. Every robotic arm knows if a customer wants pickles because it is in the programming. It makes things more likely to be perfect every time, boosting satisfaction and loyalty.

The Normalization of Human-Robot Working Relationships

BurgerBots is unique because it puts the machines in full view of its customers. People can go up to the glass and see their orders being prepared. It is a drastic change from most fast-food setups, which keep kitchens behind closed doors as if they are secrets. This restaurant is proud to have robots on staff, and it wants customers to experience the same wonder.

Exposing the public to positive, productive human-robot interactions in a professional setting is essential. It will make people more curious and excited about a future with more cobots, instead of fearful. Many resist working with robots because of predominantly negative views about smart technologies and a perceived reduction in productivity. Case studies like BurgerBots could prove the opposite and change minds.

The fortunate few working alongside the cobots also get experience collaborating with highly competent machines. It prepares them for future job opportunities where robots could work alongside them in other innovative ways. They will be ahead of the curve and know how to elevate their work alongside robotic companions.

Food for Thought on the Fast-Food Robot Generation

The BurgerBots idea introduces promise and hesitancy in the food and beverage sector. New restaurants may see their benefits and reduce human staffing needs. Alternatively, customers will have consistently higher-quality food in a fraction of the time.

The BurgerBots idea introduces promise and hesitancy in the food and beverage sector. New restaurants may see their benefits and reduce human staffing needs. Alternatively, customers will have consistently higher-quality food in a fraction of the time.

The pros and cons are apparent. However, the most pivotal influence is how this restaurant will become a shining example of human-robot collaboration in a fast-paced service environment. It could open minds to further innovations.

All images are from ABB.com.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post