BEEPTOOLKIT for Validation and verification in the electronics industry

BEEPTOOLKIT platform for ATE (Automated Test Equipment).

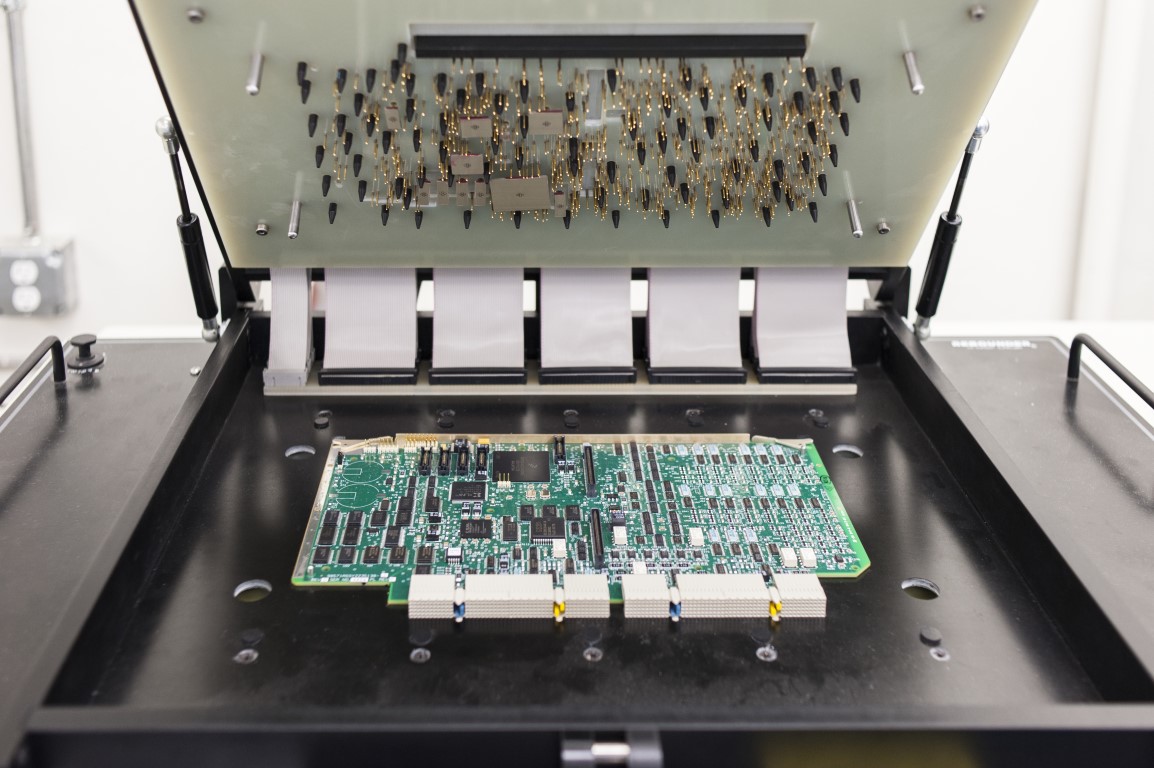

In-circuit automated testing is a technology for checking individual components on a board or circuit fragments using special equipment (ICT stations) and accessories (contact adapter - Fixture). With this test method, you can analyze individual components and analog portions of circuits. This method is successfully used in mass production of electronics, while the development of such systems is carried out by the V&V (validation and verification) departments.

In-circuit testing typically checks for the following characteristics:

- the presence of short circuits and breaks;

- the ratings of discrete components (resistors, capacitors, inductors, discrete semiconductor devices);

- availability and correct installation of microcircuits.

This testing method detects a large number of assembly defects, which is why ATE is often referred to as Manufacturing Defect Analysis.

Let's see how Tooling platform BEEPTOOLKIT can be used in ATE:

The preliminary creating of the testing algorithm consists in creating a scenario for control measurements of stresses at certain test points of the diagram. Simultaneously with the monitoring of the process, sequential measurements take place, and voltage can also be applied to certain sections of the circuit or readout of discrete signals by external measuring devices. In some cases, test programs are loaded onto the CPU.

It is important to consider critical alarm parameters in the algorithm.

So, if a voltage drop occurs when the stand is turned on, it is necessary to make an emergency shutdown, since the reason for such a situation may be a delayed reaction of protective circuits, short of component in the circuit, a critical error in the circuit scheme installation and etc.

In case of successful completion of the test, next go to further measurements of all control points, protocol logging in real time and create a final report.

Such a report undergoes an analytical check in data base with the issuance of the final test result. An example of using the platform in automated validation (ATE) of electronic modules:

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post