5 Amazing Ways Sensors Level up Next-Generation Robotics

Robotic sensor technology is revolutionizing the next generation of robots, making them smarter, safer and more capable. This tech has advanced drastically over recent years, bringing some exciting innovations to the world of robotics. What are the top ways sensors are leveling up next-gen robots?

1. Improved Safety

Improved safety is one of the top benefits of robotic sensor technology. Next-generation robots are becoming increasingly safer for humans to be around, particularly in the workplace. Previously, these machines needed to be in safety cages to prevent accidents. That’s no longer the case.

Collaborative robots (cobots) are a great example of this. These next-gen robots are designed from the ground up to prioritize employee safety. Cobots can reduce workplace injuries by 72%, according to the International Society of Automation.

This is possible thanks to proximity and motion sensors that rapidly detect human movement around the robot. Cobots also take over the most dangerous tasks in the workplace, protecting employees from high-risk scenarios.

A great example of these next-gen safety-conscious robots is Proteus, developed by Amazon Robotics. Proteus has an array of proximity sensors that can detect a human or obstacle more than a foot in front of it. It can immediately stop any time its sensors detect an obstacle, even while carrying a full load.

2. Smarter Navigation

Robotic sensor technology has completely transformed how robots navigate. Technology like proximity sensors, RFID, GPS, LiDAR, image processing and more are helping next-generation machines navigate intelligently and independently.

This is a huge step up from legacy robots, which often require manual remote operation or careful programming. Smart navigation sensors enable robots to respond to variables and obstacles in real time. This also makes them more user-friendly by reducing reliance on code.

Boston Dynamics’ Spot robot is a perfect example of the future of robotic sensor navigation. It uses a combination of stereo and depth cameras to sense and analyze its environment. There is even a “blind” version that uses non-vision-based sensors to detect the robot’s surroundings. As a result, Spot can navigate incredibly versatile and unpredictable environments with ease.

3. Optimized Performance

Improving a robot’s performance requires monitoring its mechanical health. This is exactly what sensors are doing for next-gen robots. Modern robotic sensor technology can autonomously collect and analyze performance data to detect maintenance problems. In some cases, the robot can even resolve those issues autonomously.

For example, hydraulic movement is extremely common in today’s industrial robots. It must remain smooth to achieve top performance, requiring clean fluid. Robotics technicians can combine sensors and filtering technology to keep components operating at maximum performance.

Hydraulic filters actively remove particulate contaminants from fluid but work best if inspected and replaced periodically. Robotic sensors can monitor the quality of a robot’s hydraulic fluid to detect contamination that gets through the filters. This data can tell technicians when machines need a maintenance checkup or fresh hydraulic fluid.

4. Better Dexterity

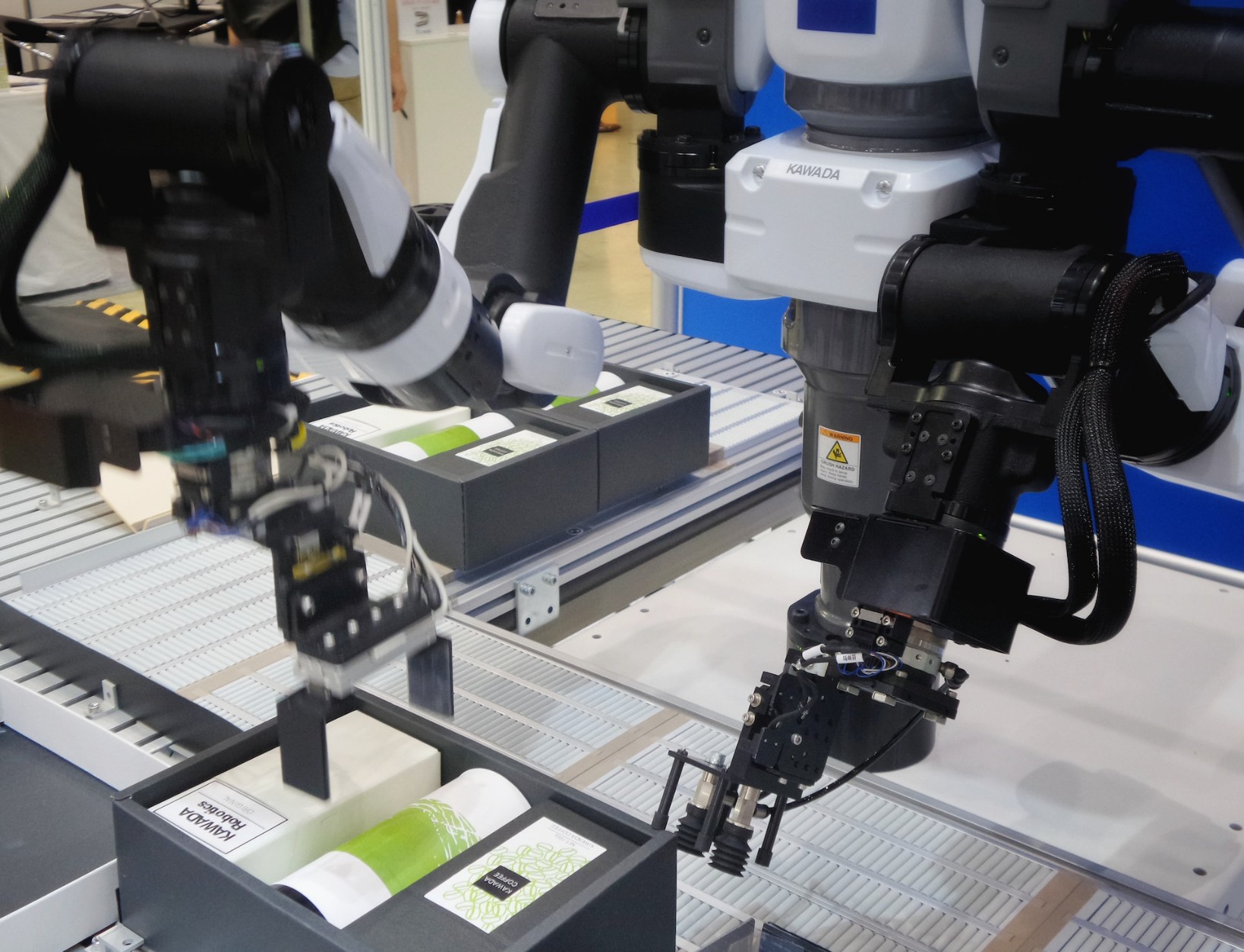

Legacy robots are often tough but not particularly gentle or dexterous. They typically can’t handle delicate objects without breaking them. Next-gen robots don’t have that problem, thanks to modern robotic sensor technology.

Sensors are significantly improving robots’ dexterity and maximizing the effectiveness of innovative end-of-arm tooling designs. A great example of this is the mGripAI developed by Soft Robotics. This unique gripper combines inflated rubber fingers with AI sensors that allow the gripper to interact with incredibly intuitive dexterity.

The mGripAI can pick up things like marshmallows, baked goods, produce and other delicate items without damaging them. The AI, vision sensors and gripper work together to identify objects to pick up and sense how much pressure they need. Designs like this are expanding the potential applications of next-gen robotics.

5. Autonomous Data Collection

Connected IoT sensors are a unique type of robotic sensor technology. Industrial IoT devices allow organizations to monitor their robots and collect valuable performance data autonomously.

IIoT sensors are great for predictive maintenance and live robot monitoring, which help organizations improve performance and efficiency. Technicians can see where robots are in a facility, view live performance metrics, remotely identify maintenance issues and more.

Over time, organizations can use IIoT sensors to build up valuable data sets on their robots and operations. The insights this information can provide are incredibly useful for optimizing robotics strategies and maximizing each machine’s ROI.

One fascinating example of IoT sensors at work in robotics is the CloudMinds service robots. These AMRs autonomously treated patients at a trial hospital in China during the COVID-19 pandemic. They use IoT for navigation, communication and sensing, all of which helped the robots aid doctors in monitoring and treating patients safely.

Robotic Sensor Technology in Next-Gen Robots

Robotic sensor technology is rapidly leveling up the next generation of robots by improving their safety features, navigation skills, dexterity, maintenance monitoring and more. Sensors are a crucial link between operators and machines, providing valuable insights about performance. Thanks to advancing sensor technology, the next generation of robots will be smarter and more capable than ever.

Thanks for helping to keep our community civil!

This post is an advertisement, or vandalism. It is not useful or relevant to the current topic.

You flagged this as spam. Undo flag.Flag Post