Hello,

I assembled the Rover Kit and it seems good but there is a problem with sprocket and motor shaft.After some seconds moving,the sprocket and motor shaft separate and there is no surprise because they are not attached in any way.How can I fix this problem?

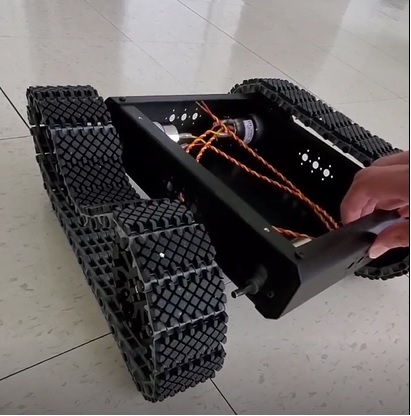

Please see the picture below for better understanding.I also have a video how it becomes separated but the forum did not let me upload it.This is a screenshot while I am moving the kit back and forth by hand.

Thank you

Do you tighten the setscrew through the hub onto the flat part of the motor shaft?

Look at the pictures for the 6mm hub:

As bmoscato indicated, the set screw in each hub needs to be tightened against the flat of the motor’s D shaped shaft. If it’s tightened against the round part, it can come off much more easily. You need to do this visually.

@bmoscato @cbenson

Thank you my dear friends,at first I didn’t understand your point,but with some research I finally found out what to do,now it is completely fixed!

Regards,

Souroosh

Well,I thought it is fixed and work properly but these set screws seem worthless and useless!@lynxmotion try to introduce a better design next time!

What’s going on? The setscrew through the collar on a D shaft is proven technology… It is used on almost every motor size except larger motors where they use a keyway, but these smaller motors are limited to this configuration. Is the setscrew hole stripped? Is it backing out (becoming loose)?

Just for the record, I don’t work for Robotshop or Lynxmotion, I’m just an aeronautical engineer, mechanic and hobbyist that was trying to help.

I know that this is not your exact configuration, but the setscrew placement is the same:

Dear bmoscato,

Please don’t get me wrong.I hadn’t complained about your comments or guiding,I appreciate all of your helps,I tagged lynxmotion to let them know their design and components are very bad in hub and screw part,the plastic set screw can be fixed in a difficult way,on the flat part of the shaft,but after spinning the shaft,the screw goes back in the hole and it’s not fixed anymore.the shaft again came out of the hub.I wasted a lot of time on this,separating the sprocket to fix the screw and then again,same problem!

Again,please accept my appreciation and respect,Mr.Bmoscato!

Hi SM75,

Can you confirm something ? The setscrews used in Lynxmotion A4WD kit should be Steel not Plastic.

The assembly section related to the hub is on P.2 of the assembly guide HERE.

You need to find the “FLAT” part of the motor shaft and tight the setscrew on that surface.

Not doing so will always result in slippage and/or damage.

All the best,

Thanks for the support.

It’s not possible to judge from a low quality image.

We don’t carry such plastic screws, are you able to make a dent with a fingernail or test with a magnet?

Those should be black oxide steel.

Hello,

I am not lying to you. Although I can make a dent and take a better picture,what are you gonna do about it?sending new metal setscrews?

Regards

This topic was transferred to internal RobotShop Support.

I’ve created a Support Center Ticket regarding this issue.

Someone in charge of the Kits will verify the hardware we have in stock to be sure.

We’ll get back to you via the ticket.