An important thing to keep in mind once you have chosen a motor based on its electrical specifications is the shaft type and size:

- Shaft Type: D-type, Round, Keyway or Spline shaft

- Shaft Length: in ''mm'' or ''inch''

- Shaft Diameter: in ''mm'' or ''inch''

- Rear Shaft: most of the time used for an encoder

Shaft Types:

The D-Shaft type proposes the ideal shape since it can fit directly into a D-shaped pulley or wheel without the need of a hub. If necessary, you can use a round-shaped hub of the same diameter of your shaft but always make sure to use a set screw to hold the parts together. The flat face of the D-shape will offer more stability once the set screw is in place and has less chance to slip, especially if the motor has a high torque.

Does a round shaft look like a bad choice to fix a wheel? Do not worry, there are plenty of ways to make the assembly stable and solid, whether it's press fitted, glued or screwed. In my opinion, the best option is to use a hub. Yet, it is probably the most expensive option, but it's the most reliable one. Make sure to use a set screw to ensure that the shaft doesn't slip and end up rotating inside the hub. We will cover the function of a hub later in the tutorial.

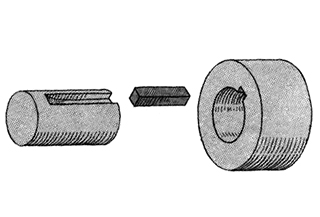

Keyway is another type of shaft that allows higher stability for big motors combined with a pulley system. It is less common in DIY projects because of the way you need to fit the key in the keyway. There are a few key hubs available on RobotShop, such as the AndyMark models.

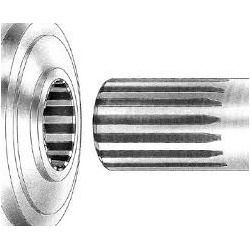

A Spline Shaft is surely more singular as it is more often used with servo motors. The big advantage is that it fits directly on the appropriate horn and offers good stability. I suggest you read the blog on Servo Spline Information from ServoCity.

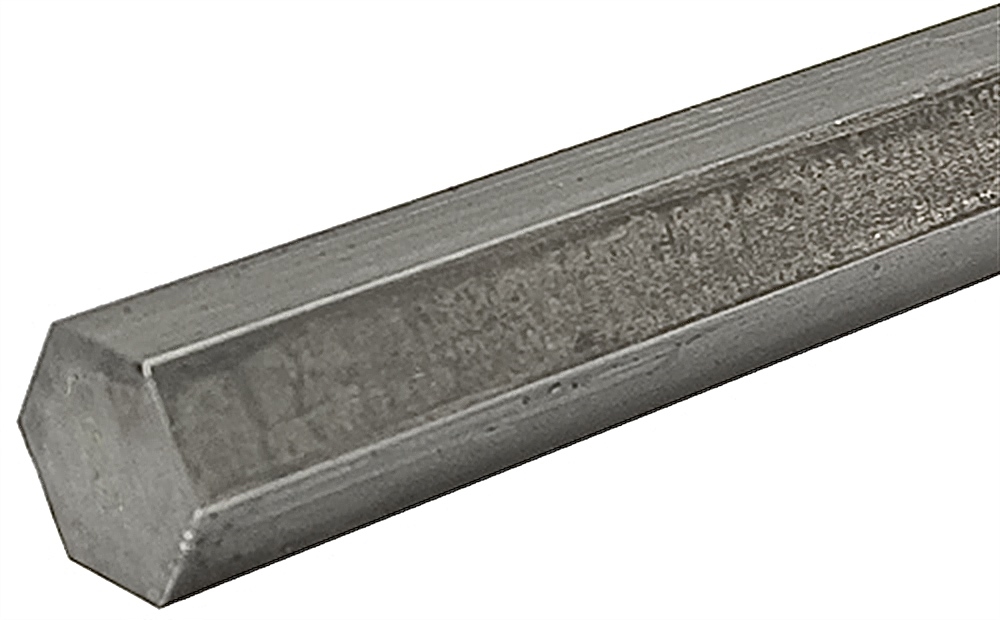

There is a variety of other shaft types like the hex, square or threaded one. Note that a motor will need the appropriate hub or coupler to be fixed to a wheel unless the wheel bore matches directly the shape of the shaft.

Do not hesitate to post any documentation or experience you have with shaft types.

Shaft Length:

The shaft length will highly influence what you can mount on your motor. Make sure the width of the wheels fits the length of your motor's shaft. If you plan on fixing a big wheel with some sprockets, make sure the shaft is long enough to fit everything needed on it.

Shaft Diameter:

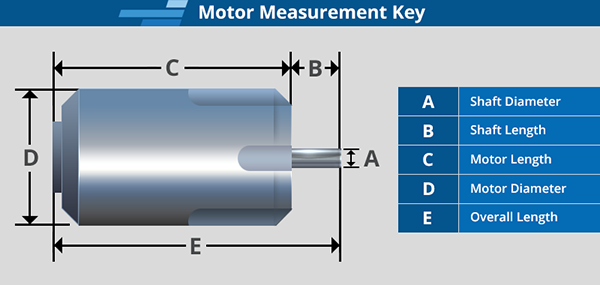

The diameter of the shaft is calculated the same way you would calculate the diameter of a circle, in inches or in millimeters. You may use a unit converter to convert inches to millimeters or vice versa. This template should help you to understand the physical dimensions of a motor:

Rear Shaft:

A motor may or may not have a rear shaft. Most of the time, in robotics, the function of the rear shaft is to attach an encoder to it. In this case, the rear shaft would be of a smaller diameter than the main shaft.

A hub is described as the center point of a wheel; it is a mechanical part composed of metal or plastic that allows the fitting between a motor's shaft and a wheel, pulley or gear. It's not always easy to match hubs with wheels and motors. Most brands that design hubs have the matching wheels. Usually, products of the same brand fit together but you want to make sure that your Nexus wheel will fit on a specific Nexus hub. This is why by the end of this tutorial you should be able to match any motor's shaft with any wheels using the appropriate coupler or hub.

First, when you choose your hub, make sure the inside diameter matches the size of your motor's shaft. Verify the shape to ensure it will fit in the hub's bore. A D-type and round shaft will fit best in a round hub and will both need a set-screw to be locked in place inside the bore. If the motor's shaft has a keyway, you will need a key hub with a matching sized keyway.

.

- In Purple: The diameter of the hole for the screw. You may find here the explanation of metric screws. 5.2mm is the diameter of the hole and X6 means there are 6 holes on the Hub.

- In Green: The first dimension is the external diameter of the hub. The second dimension is the diameter of the hub from the center of the screw holes.

- In Blue: This is the height of the hub, including the base and bore.

- In Red: This is the inside diameter of the bore. It is a really important measure that must match the size of your motor's shaft.

- In Orange: This measure is for the set screw. The screw needs to be an M5 and the length of the screw hole is 10.2mm.

Now that we know more about the motor's physical aspects, let's talk about the wheels. Wheels come in different sizes, styles, brands, and materials.

Caster Wheel

A caster wheel is pretty useful when you want to save money. It allows a robot to use only 2 drive wheels on each side and one caster wheel in the front or the rear of the robot to turn. A caster wheel is also known as a swivel wheel and as the particularity to turn on 360 degrees. Here are some examples:

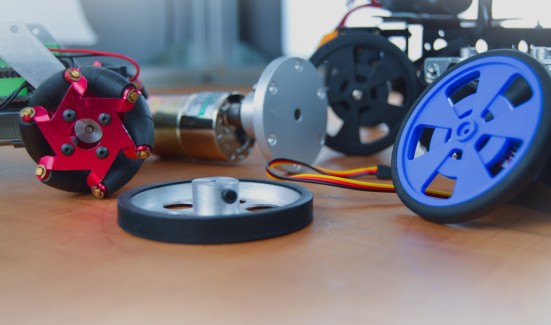

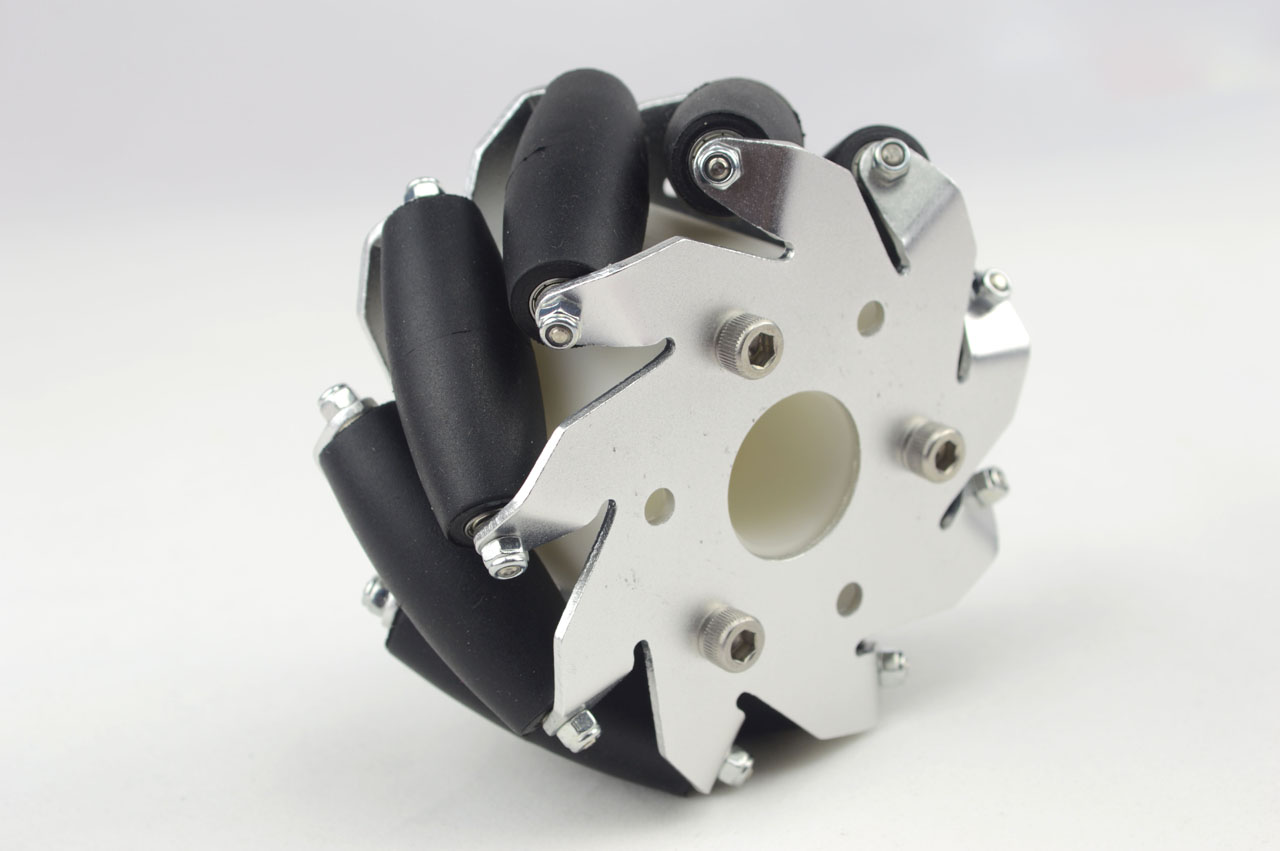

Mecanum Wheel

The mecanum wheel is a particular design that allows a vehicle to move in pretty much every direction. There are many different combinations or configurations to move in multiple directions. This also allows the vehicle to rotate on itself in any direction and move sideways. See the following picture:

Some rollers come with bearings which gives the wheels a more fluid movement.

Omni Wheel

Omni wheels are pretty similar to mecanum wheels and are also called poly wheels. In a specific configuration, they can be driven with full speed while allowing a vehicle to slide laterally. You can find some triangular configuration using 3 of these wheels to create an omnidirectional platform.

Servo Wheel

A Servo Wheel is like any other regular wheel but its main particularity is that it will fit directly on the shaft of a Servo Motor. See examples here:

Now that we've seen the different kinds of wheels, we will learn how to attach them on different motors. When the shaft connector of the wheel is shaped exactly like the shaft of your motor, (ex: D-shape, Hexagon, Square, etc) you may directly connect the motor to the wheel. In some other cases, you could press fit a round-shaped shaft inside a wheel with the exact same shaft connector diameter. Note that in high torque situation, there is a risk that the motor shaft slips inside the wheel's bore. Sometimes, you will be lucky enough and find a wheel with a set screw. In that case, you will only have to match the shaft diameter with the bore diameter of the wheel. When none of the preceding options are available, the hubs will come really handy. Since you now know how to read the dimension of a hub, we will inspect the dimensions of a wheel and see which hub would fit.

- In Purple: The diameter of the hole for the screw. 5.2mm is the diameter of the hole and X6 means there are 6 holes on the wheel.

- In Green: This measure is the circular dimension from the center of the wheel to the center of the screw holes.

- In Blue: 60mm is the width of the wheel including the nuts. 50mm is the width of the wheel without the nuts.

- In Red: This is the inside diameter of the wheel's bore.

- In Orange: This is the diameter of the whole wheel. 100mm

The dimensions of the wheel detailed above match the dimensions of the hubs we checked earlier in this tutorial. This means that you could easily fit the hub on the wheel and then fit the shaft of a motor on the hub.

Ready to face the mysterious world of motors, hubs, and wheels? I know that there is a ton of other equipment and material not mentioned in this article but I highly encourage you to post your questions, comments, and experiences in the comments to help improve this tutorial so we can democratize robotics and make it accessible to anyone.

Also, don't miss this amazing blog by CBenson about Hubs and Mounts Patterns. I think it covers all the missing information and additional details!