An actuator is a device that converts electrical energy into physical motion. Choosing the right actuators (which include DC motors, gear motors, servo motors, linear actuators, muscle wire, etc.) requires imagination and a bit of math and physics. The vast majority of actuators produce either rotational or linear motion combinations thereof can lead to complex motion. Keep in mind there are always new and innovative products being brought to market and nothing is set in stone.

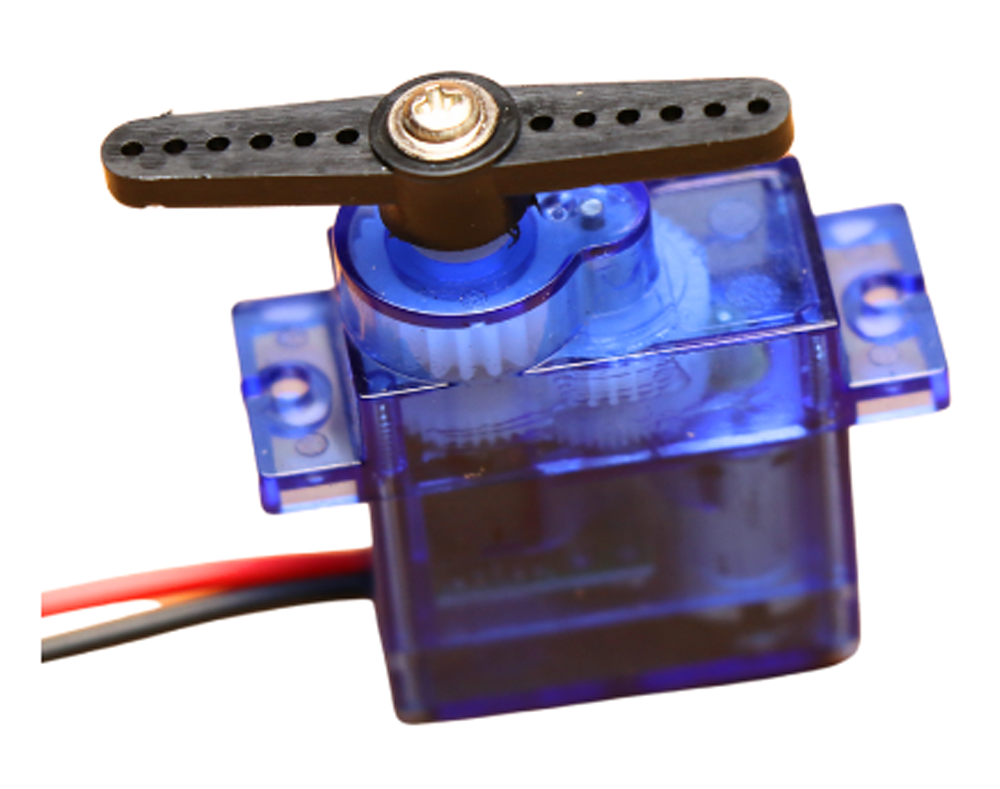

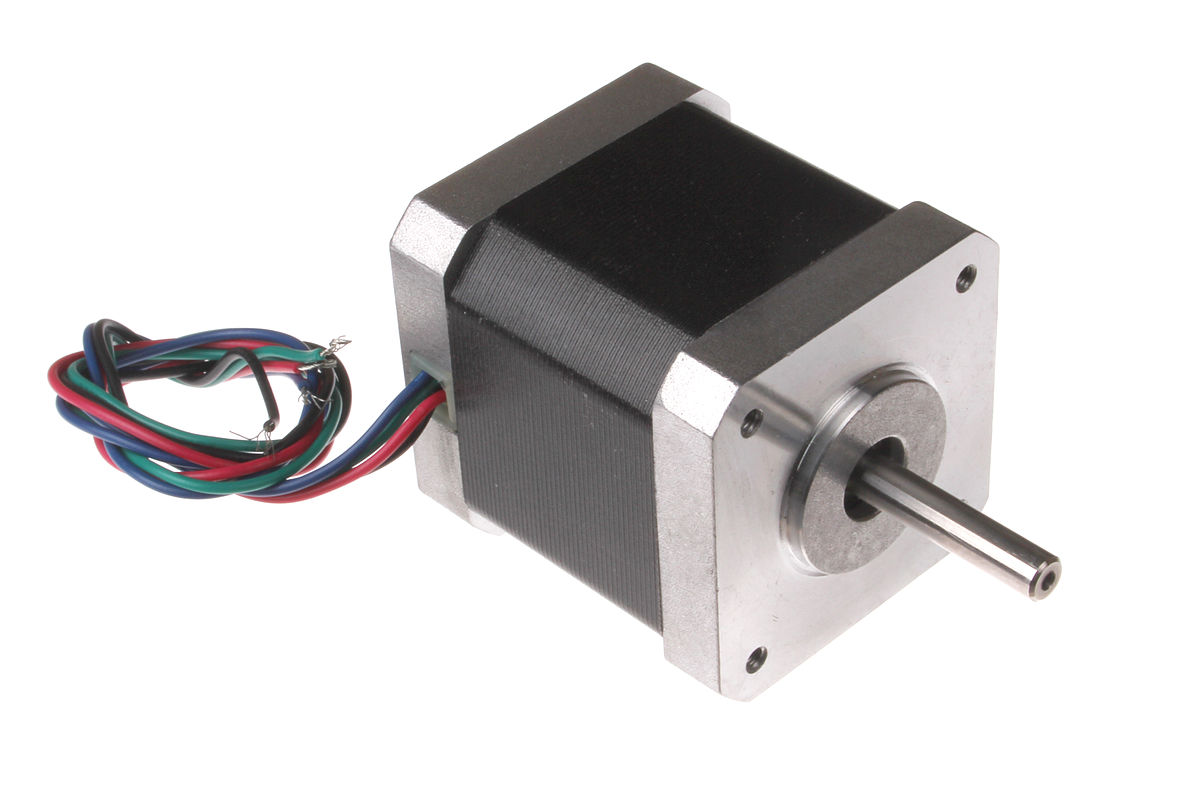

Actuators that produce ROTATIONAL motion include:

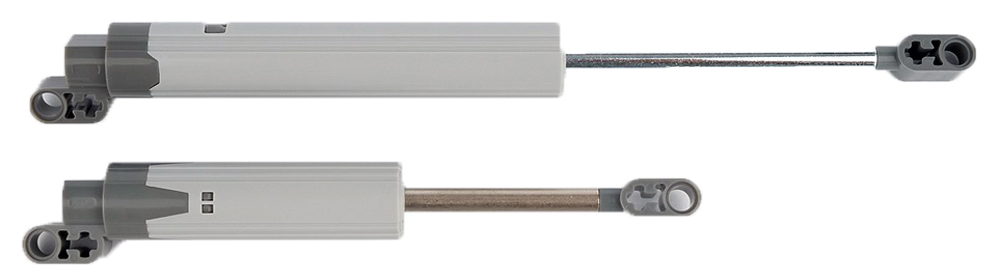

Actuators that produce LINEAR motion include:

To help you find the right actuator for the right task, we have developed the following questions to guide you in the right direction:

Drive motors must move the weight of the entire robot and should therefore have a gear down. DC gear motors are the ideal choice for robots with wheels as they provide continuous rotation, and can have optional position feedback using optical encoders.

Lifting a weight requires significantly more power than moving a weight on a flat surface. The speed must be sacrificed in order to gain "torque" and it is best to use a gear motor with a high gear ratio and a powerful DC gear motor. Consider using a system (either with gears, clamps, or others) that prevents the mass from falling due to loss of power.

If the range is limited and the torque required is not significant, a servo motor is ideal. Servo motors are offered in a variety of different torques and sizes and provide angular position feedback (most use a potentiometer, and some specialized ones use optical encoders).

Stepper motors (coupled with a stepper motor controller) offer very precise angular motion. They are sometimes referred to as servo motors because they offer continuous rotation. Some continuous rotation digital servo motors, which often use optical encoders, now offer the same functionality as servos but with very high precision.

Linear actuators are best for moving objects and/or positioning along a straight line. They come in a variety of sizes and configurations. If your motion requires far less force than that of a linear actuator, consider muscle wire. Air muscles are an excellent choice when considering the simulation of organic muscles but require a slightly more mechanically complex control setup.