SL 3D Printing

SL was the first type of printer developed back in 1983. It was what started AM. It worked by tracing a layer out of photo curable resin and immidiately hardening it with a UV lamp. It would do this upon layer upon layer. This type of 3D printing is hardly used anymore for UV resin is incredibly toxic and FDM manufacturing replaced this type of manufacturing.

FDM 3D Printing

FDM printing works taking a very fine tuned hotglue gun and cooling it off to form a part layer by layer after tracing out each layer. FDM manufacturing will be extensively covered in this series since it is mostly all I know in this field of manufacturing. It is the most popular type of 3D printing since it is all we tend to see from hobbyist or RepRappers (reprappers are people that 3D print parts for 3D printers). RepRappers can 3D print up to 85% of a 3D printer itself.

SLA 3D Printing

SLA 3D printing is the process of using a laser to trace out layers of a print and forming an object layer by layer. This is by far the simplest kind of 3D printer but also by far the most detailed form of 3D printing for you can get object resolution you can't get from any kind of 3D printer to date.

SLS Printing

SLS printing uses a laser to sinter out parts of a print layer upon layer by sintering out powder. This is the only kind of metal 3D printer out there for it can print metal like titanium. Doctors use this kind of 3D printing to print prosthetic bones for it can print titanium which bonds to bone really well. Your hip or knee replacement was probably made with this. This is by far the most expensive and versatile kind of 3D printer since it is still heavily patented by printer companies and not much research has been done to make it opensource unlike FDM printing.

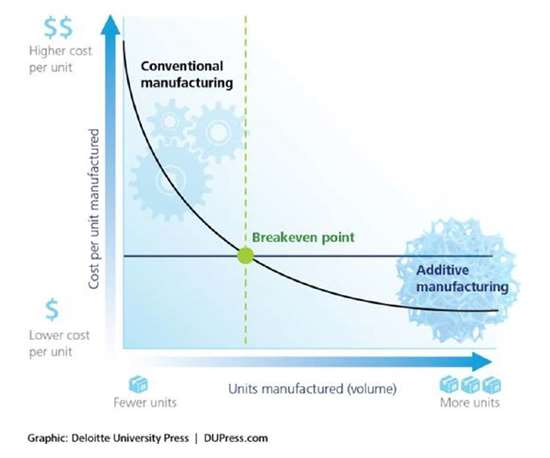

Injection Moulding is how most plastic pieces are made in your household such as legos to even car bumpers. There is a major difference in production volume to this and cost of production per volume as well.

This shows an example of how injection molding compares to 3D printing in production. 3D printing is clearly shown as better in lower production then injection molding for injection molding has exponential growth.