Tulip manipulator

I had this idea after I studied a tulip on my roof garden. In the morning the blossom opened, in the evening the blossom closed. If I forgot to water it, it let its head hang down. During the day the flower always tried to move to the brightest sunlight. The blossom is like a gripper, I thought, and the stem like a thin robot arm (maybe I should stop taking these drugs...).

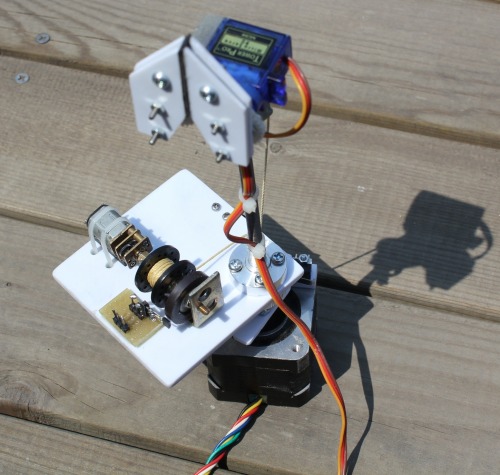

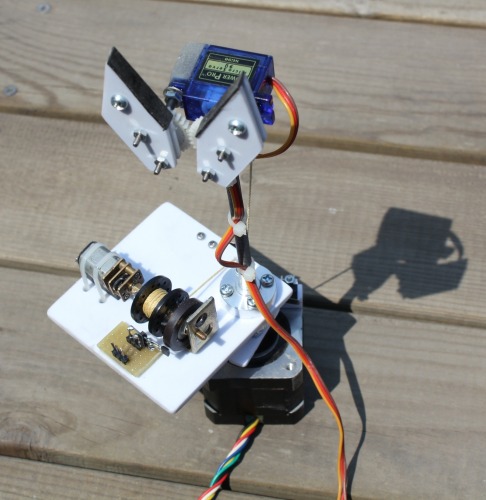

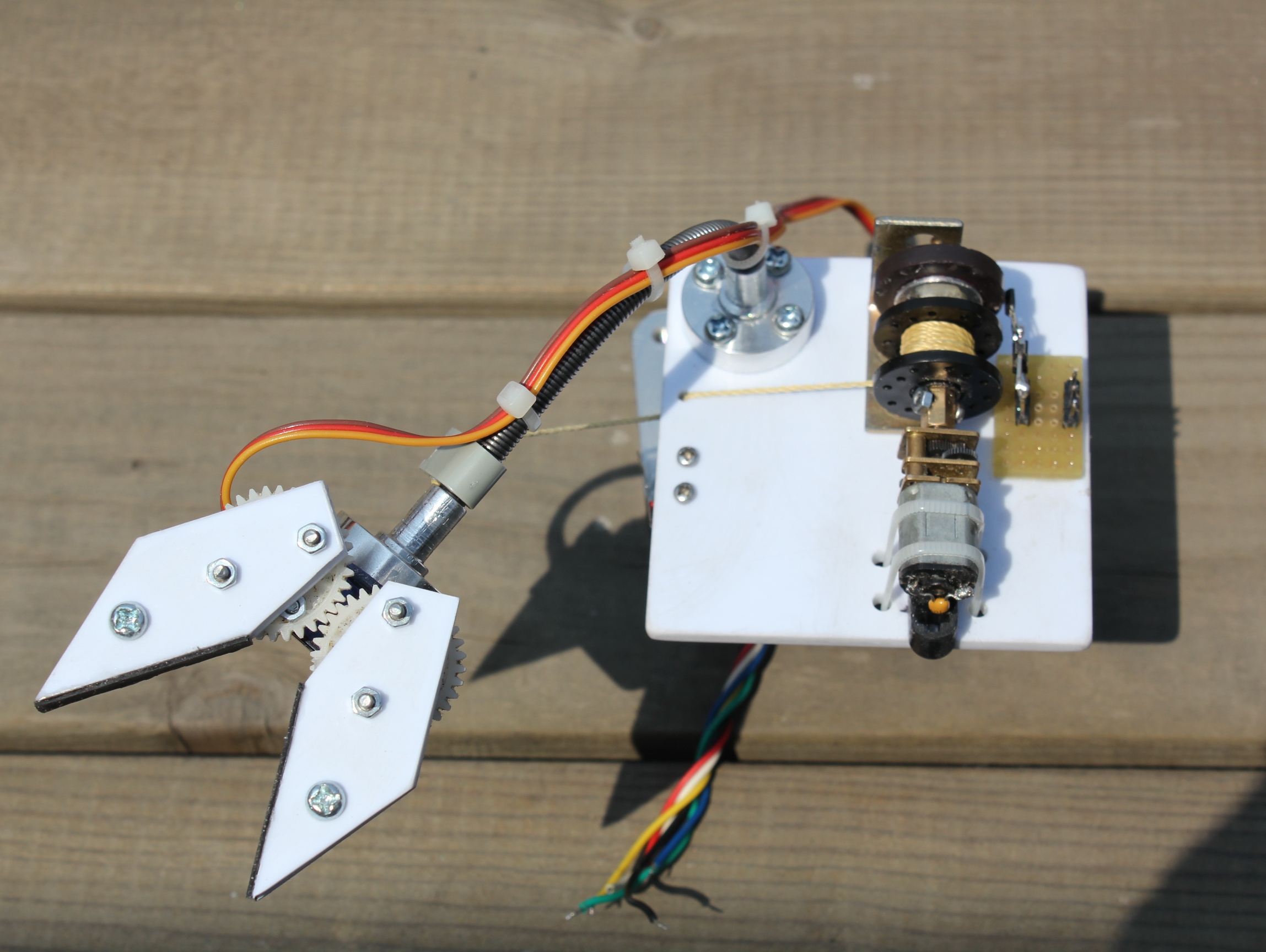

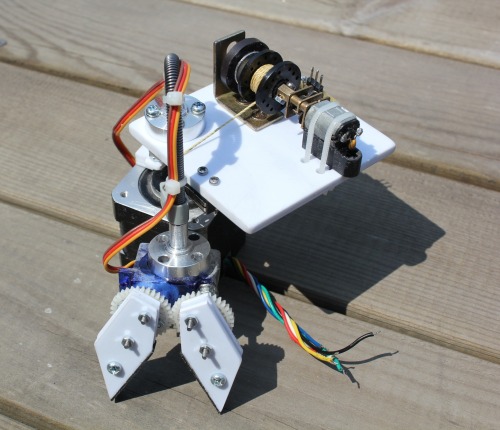

However, next day I started to construct the robot prototype. The stem is made from a strong spring, a former toy RC TX antenna. The spring is actuated by a small cable winch. The cable winch is driven by a small geared motor and controlled by a magnetic encoder and a micro switch (position calibration at start up).

The gripper is made from 2mm ABS sheet and two small plastic gears and actuated by a micro servo.

The turn table is driven by a common unipolar stepper motor and has a micro switch on one of its two end positions for position calibration at start up too.

The next idea would be to construct a spring whose spring force could be electrical manipulated on different positions, so if you force it down, it only bent on according manipulated positions.

TBC

Pick small things up and put them down

- Actuators / output devices: 1 x Micro servo, 1 x geared motor, 1 x stepper motor

- Control method: autonomous

- CPU: Picaxe 28x1

- Power source: 12v

- Programming language: Picaxe basic

- Sensors / input devices: 2 x micro switch for position calibration, 1 x magnetic encoder

- Target environment: indoor on smooth surfaces