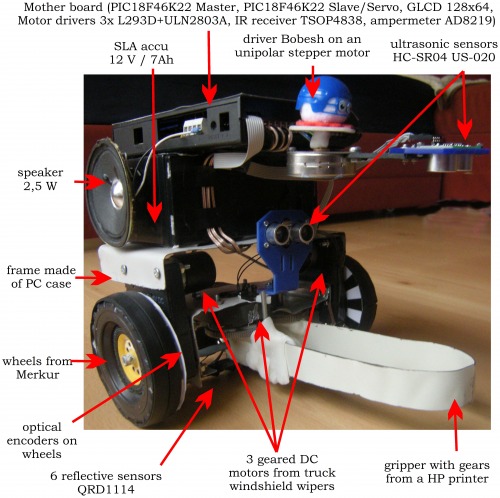

Tractorbot Bobesh Mk2

Tractorbot Bobesh Mk2 is my second robot and it’s an upgrade of Tractorbot Mk1. It helped me to win two bronze medals this year at the national championship in electronics and radio-electronics of youth and at the Czech Robotic Day in Prague on 13th and14th June 2015 at the Ketchup House contest.

Functions:

- IR remote controlled

- Programmed for Ketchup House

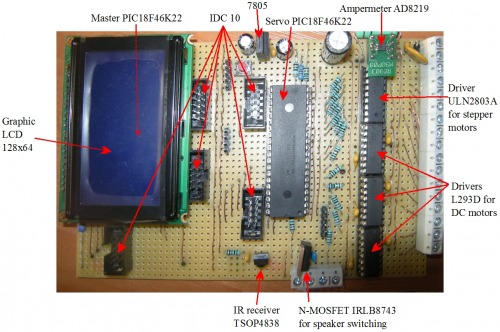

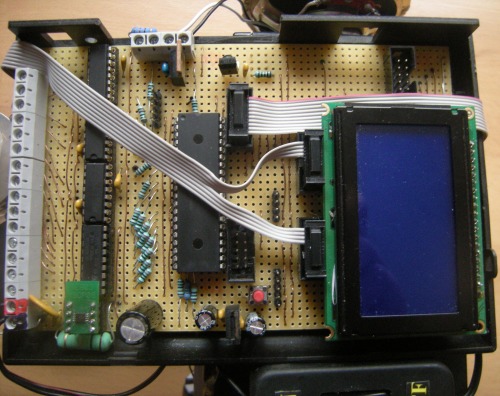

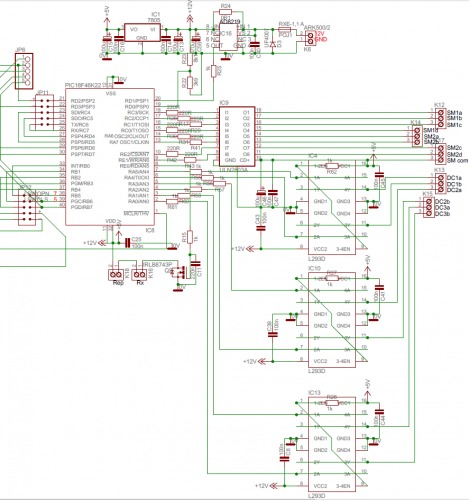

Home-made robotic control board with a “dual-core processor”:

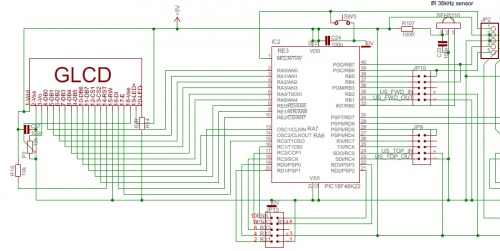

PIC18F46K22 as Master MCU

- GLCD 128x64

- IR-receiver for remote control systems SFH 5110-38

- 3x IDC 10-pin connectors with 20 free I/O pins of MCU (used to connect 3 external sensor boards)

- UART communication with Slave MCU

PIC18F46K22 as Slave/MultiServo MCU

- 3x motor driver L293D with paralleled outputs for 3 bidirectional DC motors (max 1.2 A each)

- 1x Motor driver ULN2803A for 2 unipolar stepper motors (0.5 A per phase each)

- N-MOSFET IRLB8743 for speaker switching

- Voltage divider for battery control

- Digital ampermeter AD8219 for total current measurement

- 2x IDC 10-pin connectors with 16 free I/O pins of MCU (used to connect 2 mechanical limit switches)

Motors:

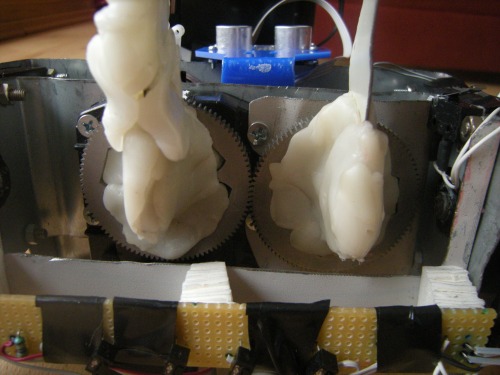

- 3 geared motors salvaged from truck windshield wipers, originally for 24 VDC

2 motors for differential drive

1 motor with a gear from HP DJ printer used for a gripper (finally not applied for collecting ketchup cans; fixed wide-open collector used instead)

- one unipolar stepper motor from a printer (just for fun)

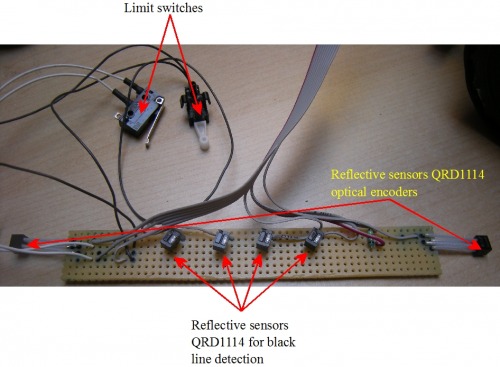

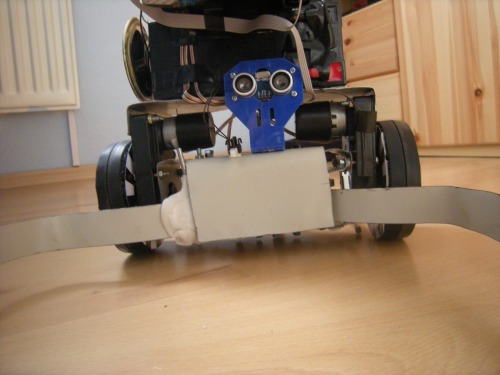

External sensors boards:

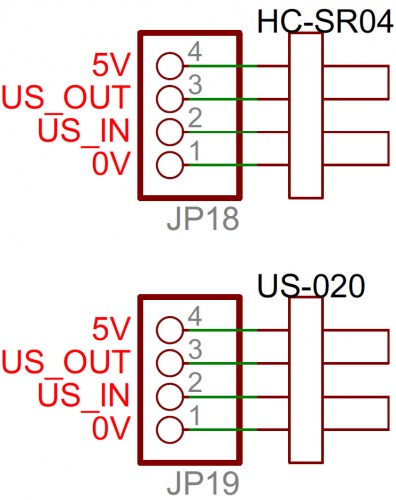

- ultrasonic ranging module HC-SR04 for an opponent detection

- ultrasonic ranging module US-020 for ketchup can detection (finally not used)

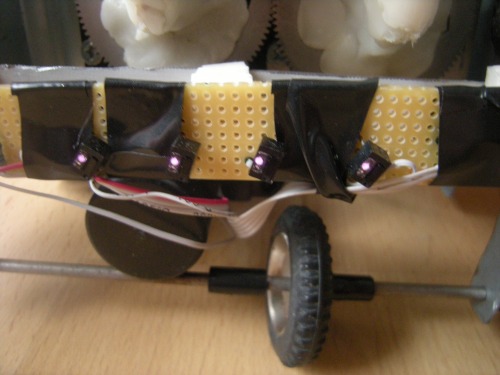

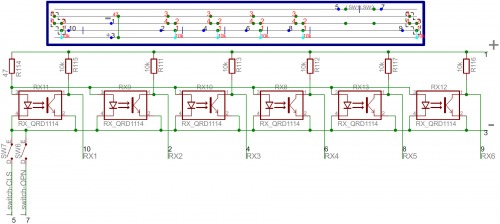

- 6x reflective object sensor QRD1114 (5x black line detection + 1x optical encoder) + 2 mechanical limit switches

Power:

- 12 V SLA battery 7 Ah for motors and a speaker

- 7805 for MCU and sensors

Mechanical parts:

- A frame made of PC case

- Wheels from Merkur (Czech Meccano)

Robotic control board:

External sensor board:

Front view:

Top view:

Bottom view on QRD1114 external board:

Bottom view on gripper gears:

Functional scheme of the control board - Master part:

Functional scheme of the control board - Slave part:

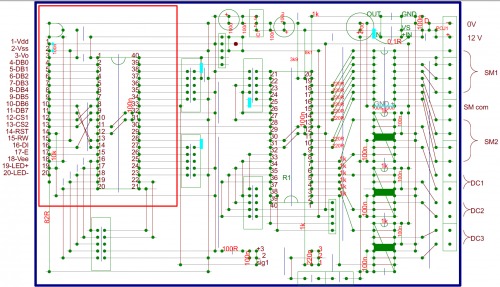

Soldering scheme of the control board on universal PCB (e=0.1"):

Scheme of the external sensor board:

Scheme of the ultrasonic module:

What to improve in the next version of Tractorbot Mk3:

- To double battery voltage to 24 V for increasing the robot´s speed.

- To add an electronic compass for position control after getting lost in the playground.

- To improve opponent detection by moving ultrasonic ranging module.

A robot made for the Ketchup House contest for the Robotic Day 2015 in Prague with a home-made robotic control board with a “dual-core processor”.