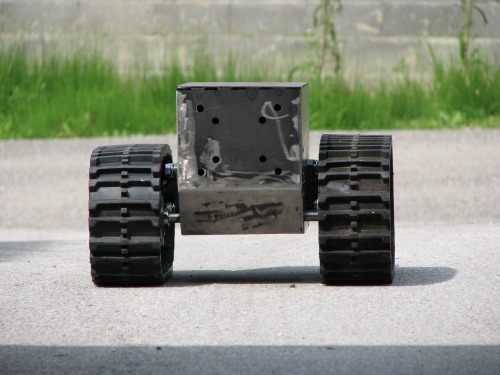

TrackRobot

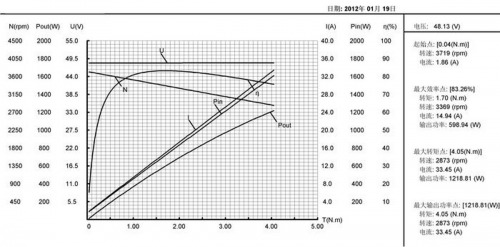

Specs:

--> size: 500 mm X 500 mm or 20" x 20"

--> weight: 60 kg or 130 lbs

--> payload capacity: 160 kg or 350 lbs

--> ground clearance: 80 mm or 3.15"

--> max speed: 4 m/s (cca. 15 km/h or 10 mph)

--> max torque: 30 Nm or 22 ft lbs on each track, total 60 Nm or 44 ft lbs

--> run time: at full power 1 hour (3000 W)

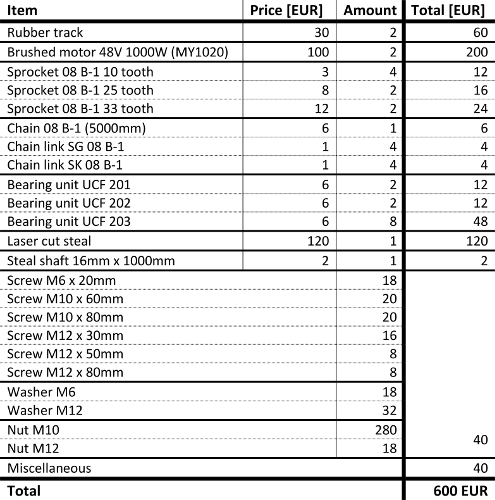

--> 2 motors: each 1000W 48V

--> 1:8.25 gear reduction

--> battery: 48V 2kWh

Custom Arduino motor controller:

--> Arduino Mega

--> BTS7960 module 2PCS

--> Source code: https://github.com/Hrastovc/Arduino-TankDrive

After two years of planning, assembly finally began:

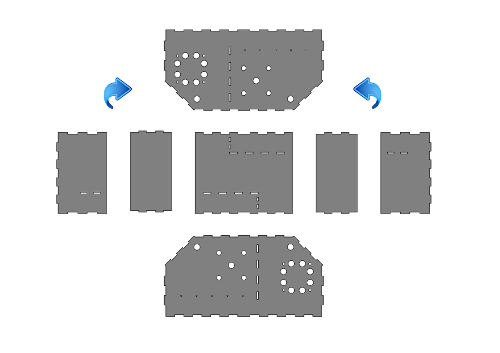

Laser cut steel:

Motor characteristics:

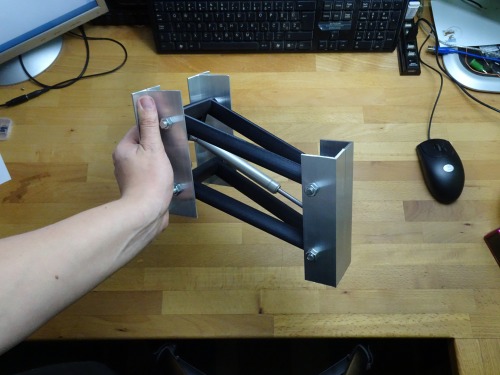

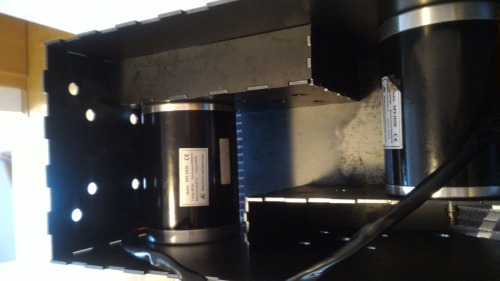

Assembling the "shell":

Lots and lots of screws:

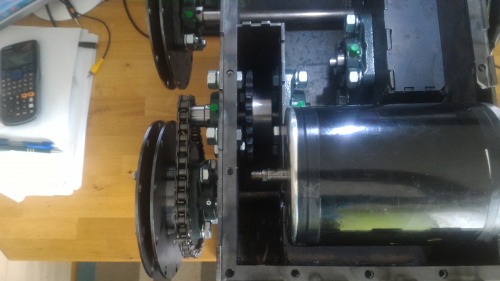

Basic structure with integrated motors:

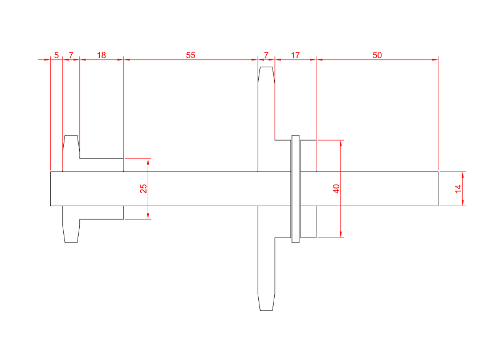

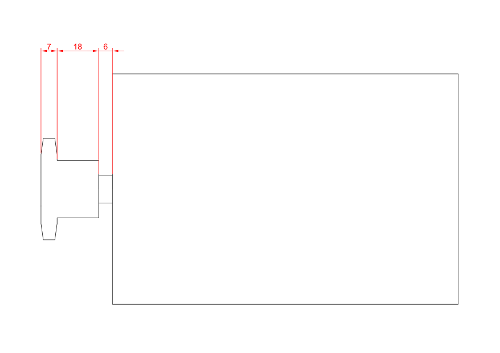

Shaft specs:

Smaller sprocket (on the left) should be welded on, but only on the left side and not the right side.

The bigger sprocket should be fixed with a pin through the shaft (needed for assembly sequence).

Sprocket on a motor shaft:

Chain drive:

First testing:

----------------- UPDATE #1 -----------------