Evolution...

First of these lessons was speed. You've got to be able to effectively chase opponents in the arena wheras my first robot largely had to rely on the opponents running into it as it was too slow to catch them. The fist version used a pair of 1200W electric skateboard motors with internal hall effect position encoders. In this second version I opted for something a little more powerful:

These are brushless (BLDC) motors from heavy-lift crop-dusting multi-copters. 3350W a piece! A pair gives an equivalent of about 9 horsepower! this gives the 13.7KG robot a 0.66 hp/KG power-weight ratio. As a fun comparison, a Bugatti Veyron sports car has a power to weight ratio of 0.523 hp/KG. So TRAC actually wins out (for the 10 or so seconds before the motors overheat and melt!).

All those horses aren't much use without a good jockey at the reigns, and these motors are sensorless! To give my poor motor controllers (Jockeys) some hope, I attached some reigns in the form of magnetic encoders mounted to the back of the motors. These allow the motor controller to accurately sense the motor's rotor position relative to the magnets and apply power to the motor coils as appropriate. A sensorless setup often uses back emf (measuring voltage induced by the magnets on the motor coils during neutral switching stages) to estimate position. This is inaccurate especially at low speeds and tends to produce stuttering or slipping and wastes many powers. Hall effect sensors are an improvement over sensorless, however due to limited resolution still produce stuttering at low speeds. A high resolution encoder like these produces no stuttering - just unrelenting torque!! Perfect for a direct drive setup like TRAC's!

Now I need to deliver that torque to the ground. It's wheel time! I also needed to remove as much heat as possible from my motors - overheating was another problem in the first version. After having sworn off 3D printed wheels after my experiences with the first robot I decided it would try again with ABS (instead of PLA) and better mechanical wheel support. This allowed me to build turbine fans into my wheels. In theory, this will work in trio with the natural centrifuge effect of the spinning body as well as air scoops to pump air from the outside, into the centre of the robot, then through the motors, and out the sides. I'm sure at the least it can't be worse than the last one (which was a sealed box)!

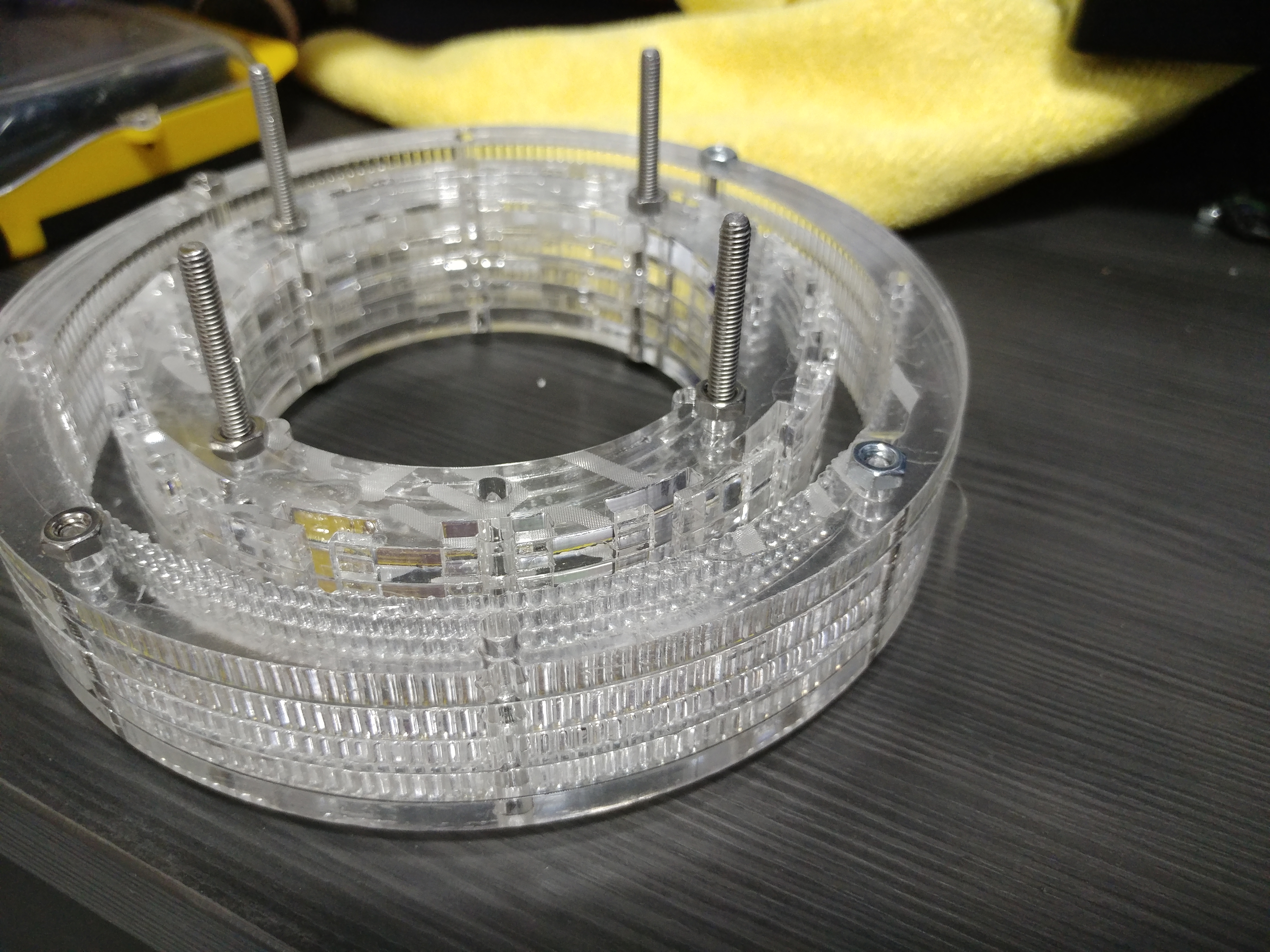

To prevent the wheels from rubbing against the chassis (this caused my PLA ones to melt) I added some extra thrust bearings to support the entire motor assembly under the centripetal spinning forces:

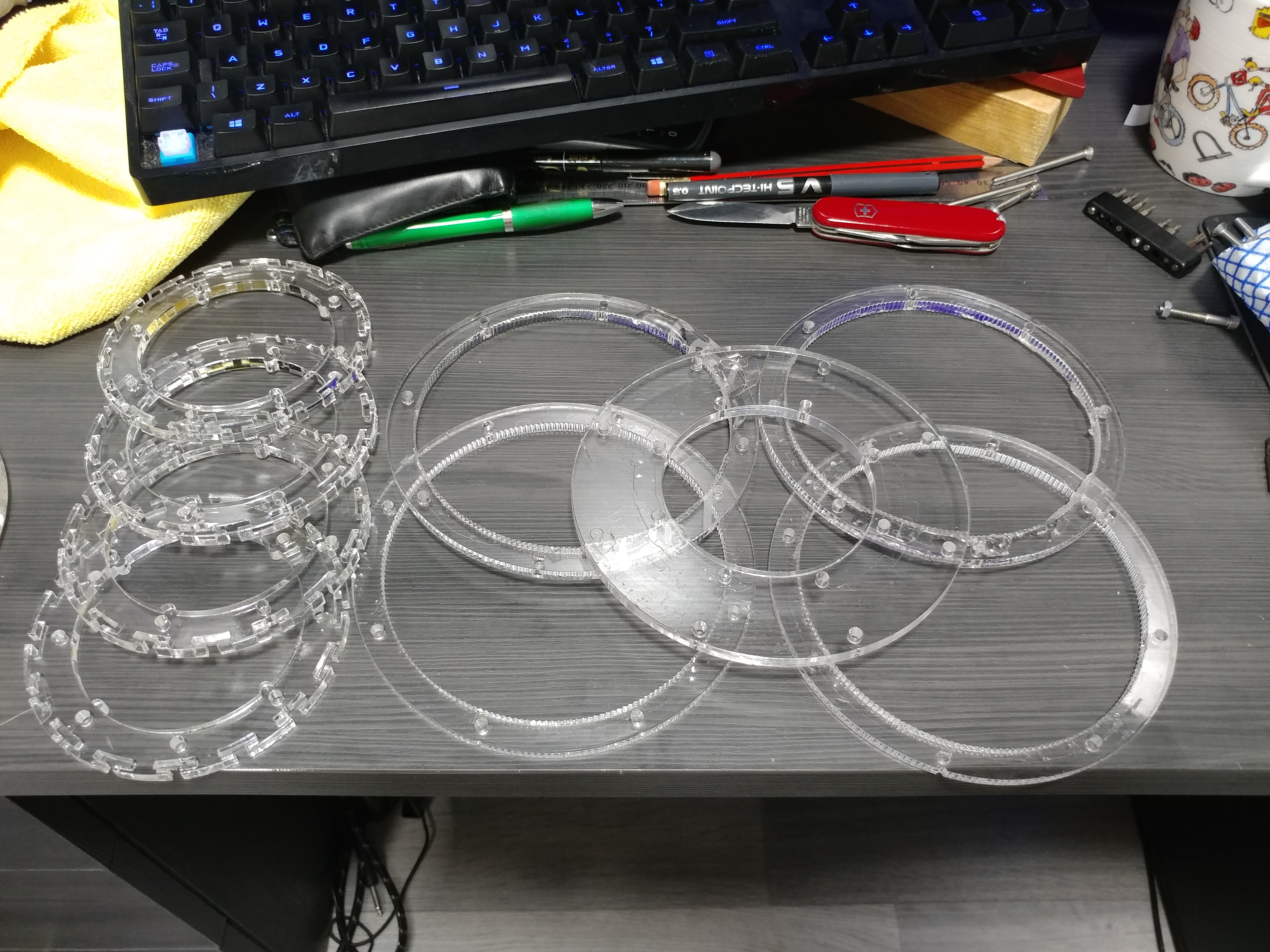

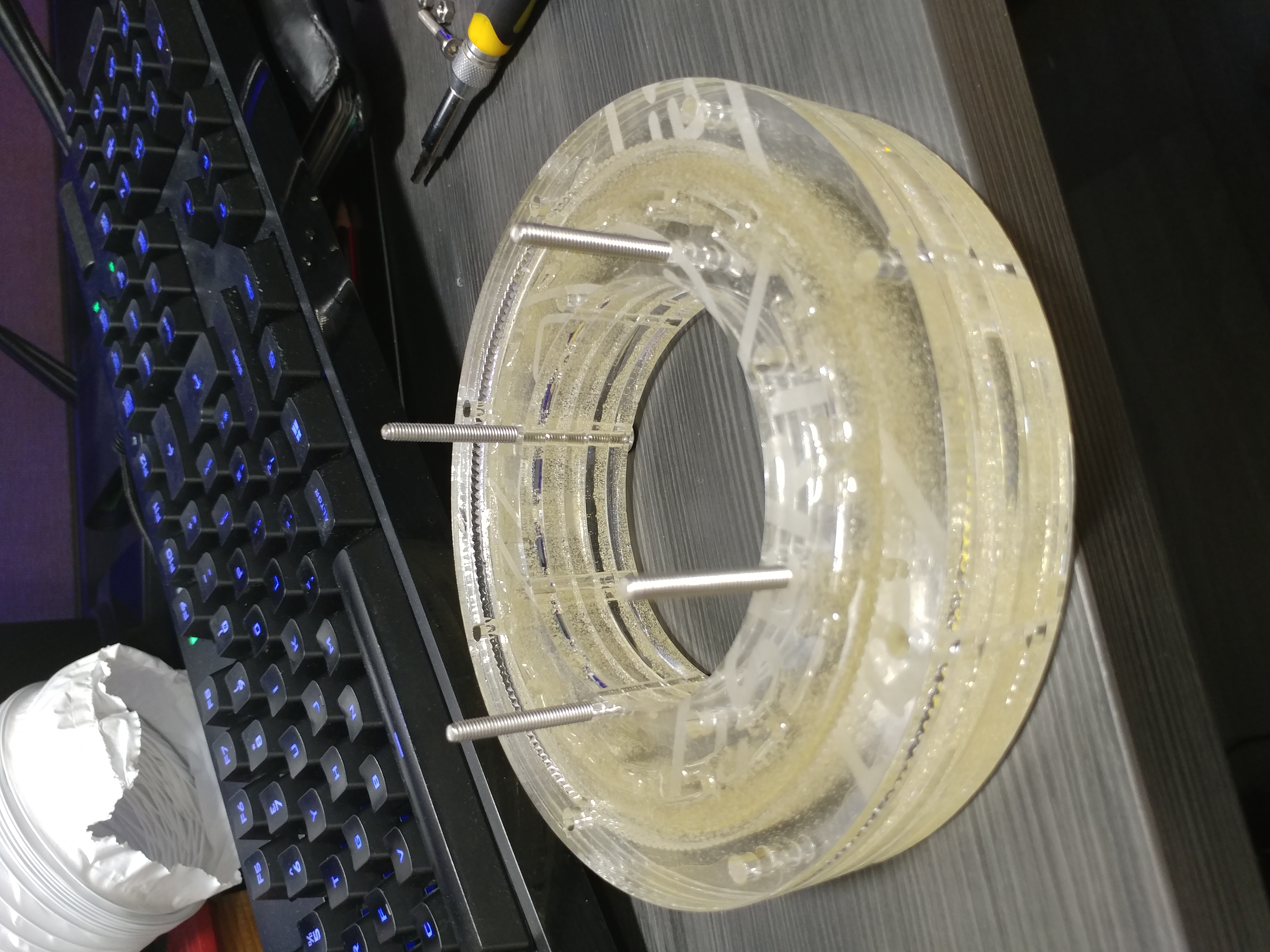

The next problem was tyres. My first version used silicon exhaust hose cut into thin sections. This stuff wears through very fast and makes one hell of a mess! (I was putting on a fresh set of tyres for each fight with the first version!) For this version, I decided to be a little fancy and mould my own polyurethane tyres. I designed some moulds using layers of lasercut parts, and ordered some rubber samples. I eventually settled on polycraft FC8000 as it had the best grip of my samples.

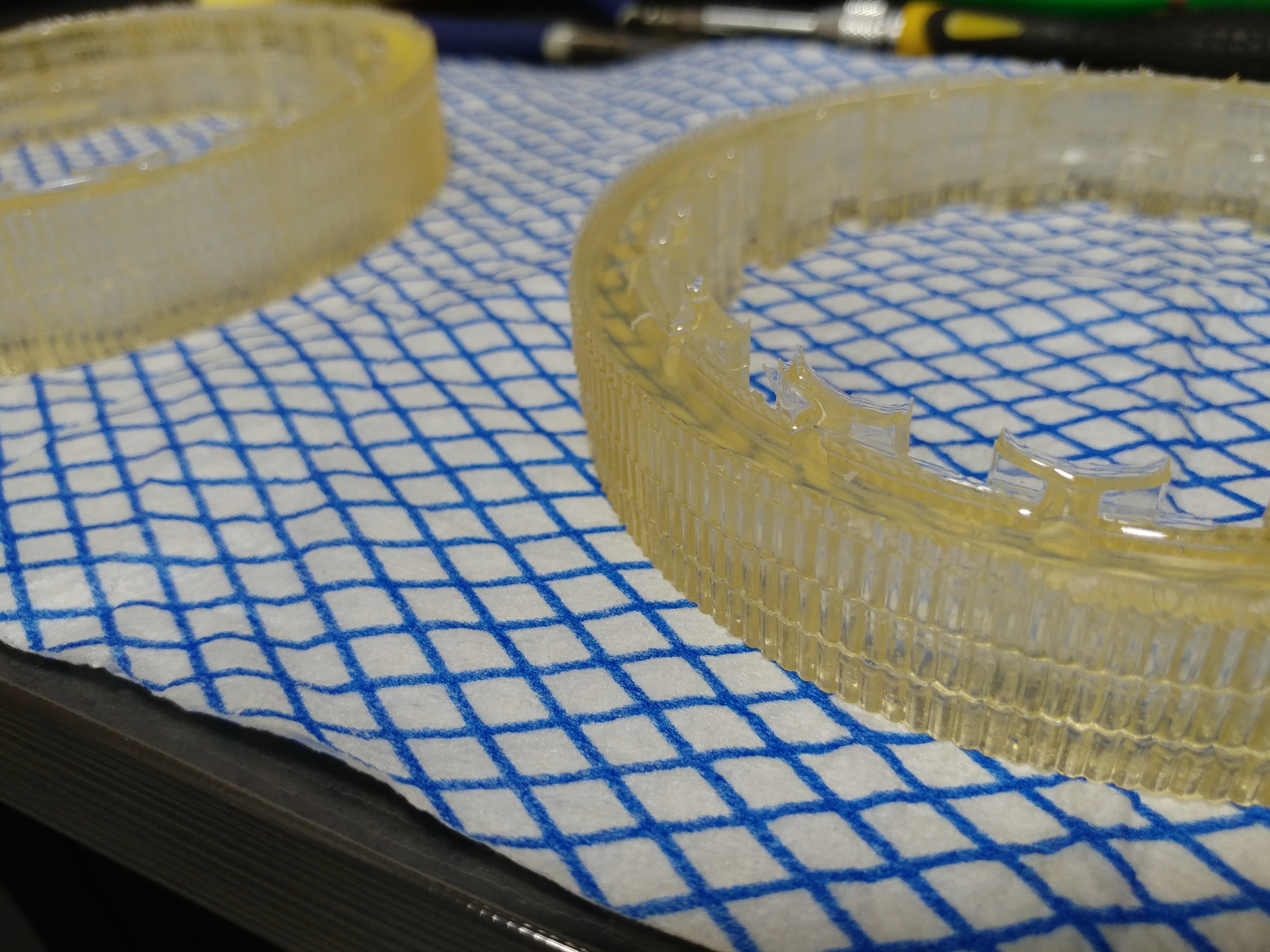

First set got too much air in the liquid rubber when mixing and came out very brittle:

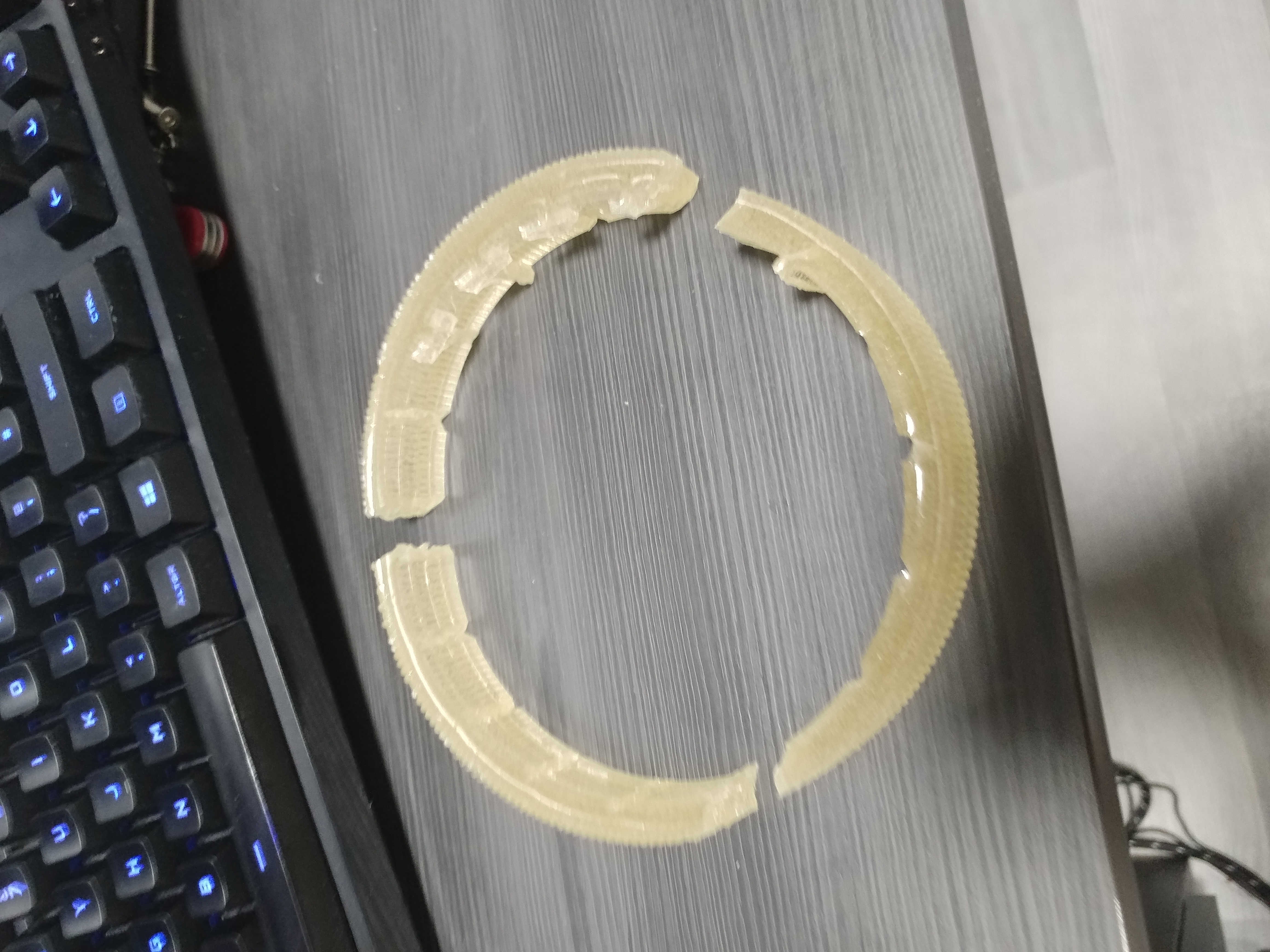

Second attempt came out much nicer!:

Next was the weapon engagement. The first version had problems getting it's weapon to connect effectively - it liked to glance off surfaces instead of digging in. I have taken some inspiration from Tom Brewsters single tooth weapon bars in Monsoon, Tauron and Straddle:

Hopefully the single angled tooth should get larger engagements and have more of a bite! The main bar is 2.6KG's worth of 20mm aluminium with a 2.3KG hardox tooth on one end and a 3KG counterbalence / armour bar on the other. This makes for a ~53 cm weapon bar weighing in around 7.9KG!

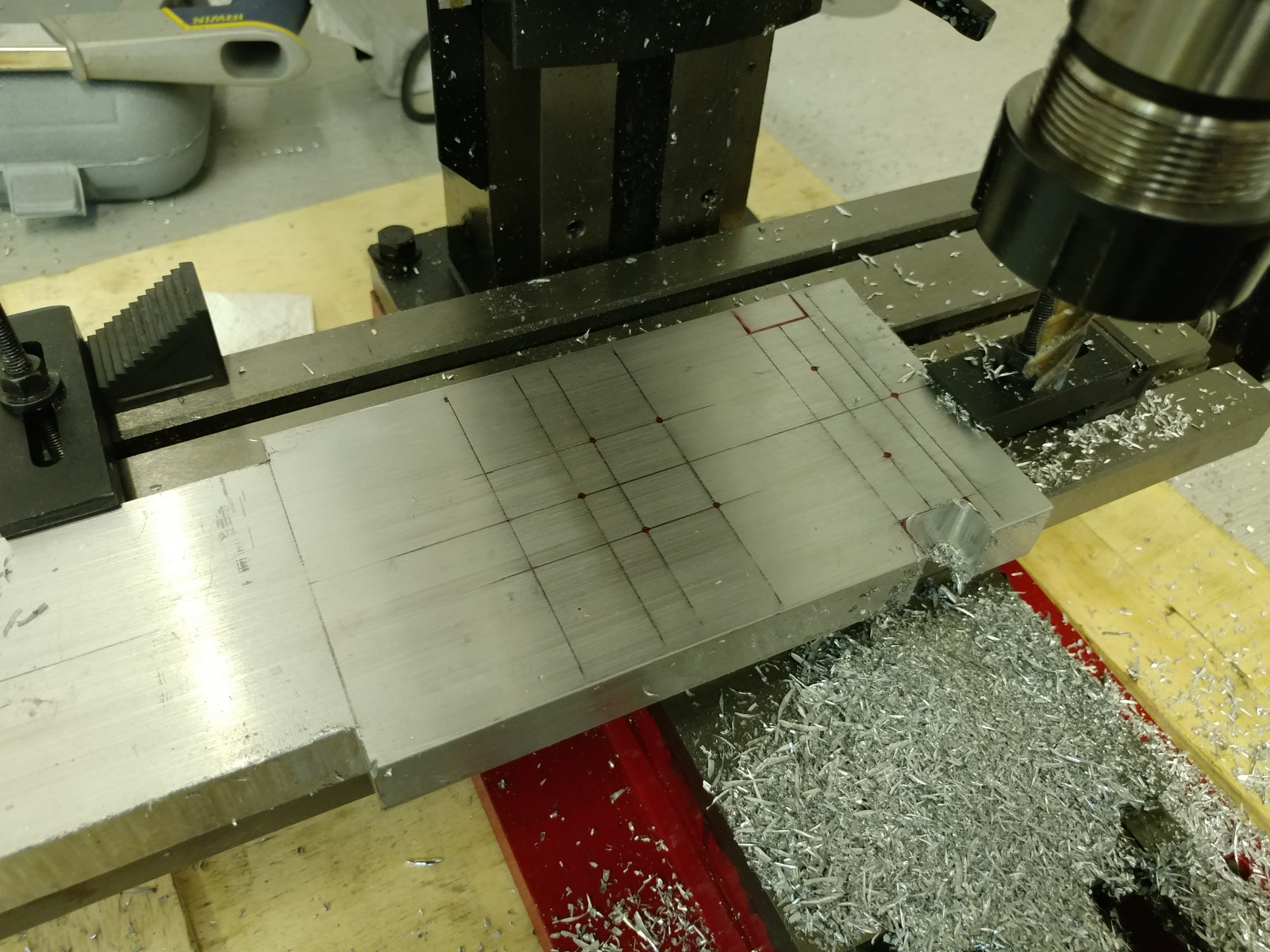

Back to the mill...

Pretty happy with the result! The hardox teeth will eventually be sandwiched between two steel plates over the aluminium bar to ensure they cant fall off up or down.

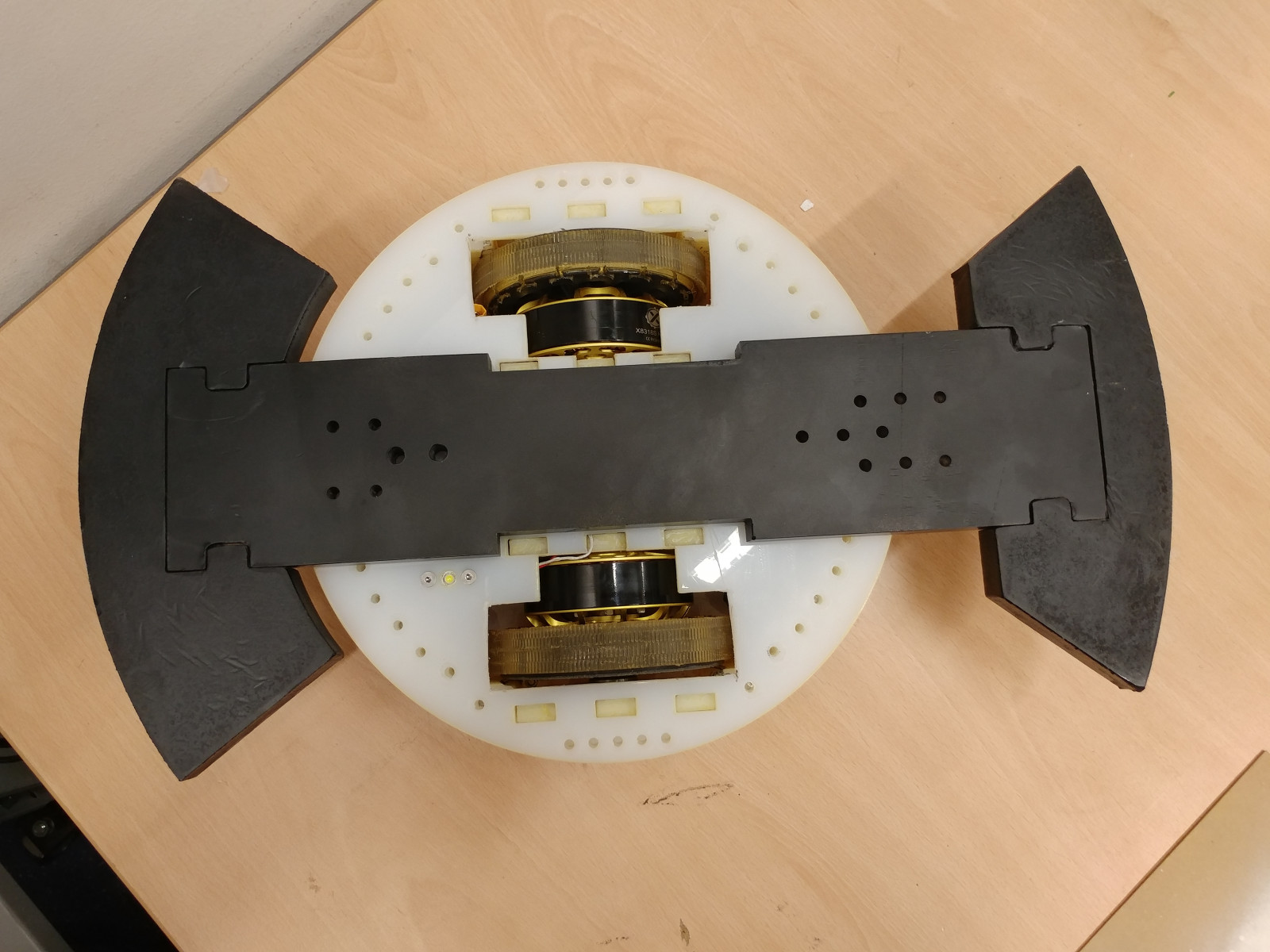

Next was the Chassis. The chassis from the first robot (made of layered lasercut nylon) actually held up brilliantly - barely showing any signs of wear, so if it ain't broke...:

The chassis for TRAC had to be deeper to house the larger motors - a total of 14 layers! I also left a bit extra space for electronics & battery:

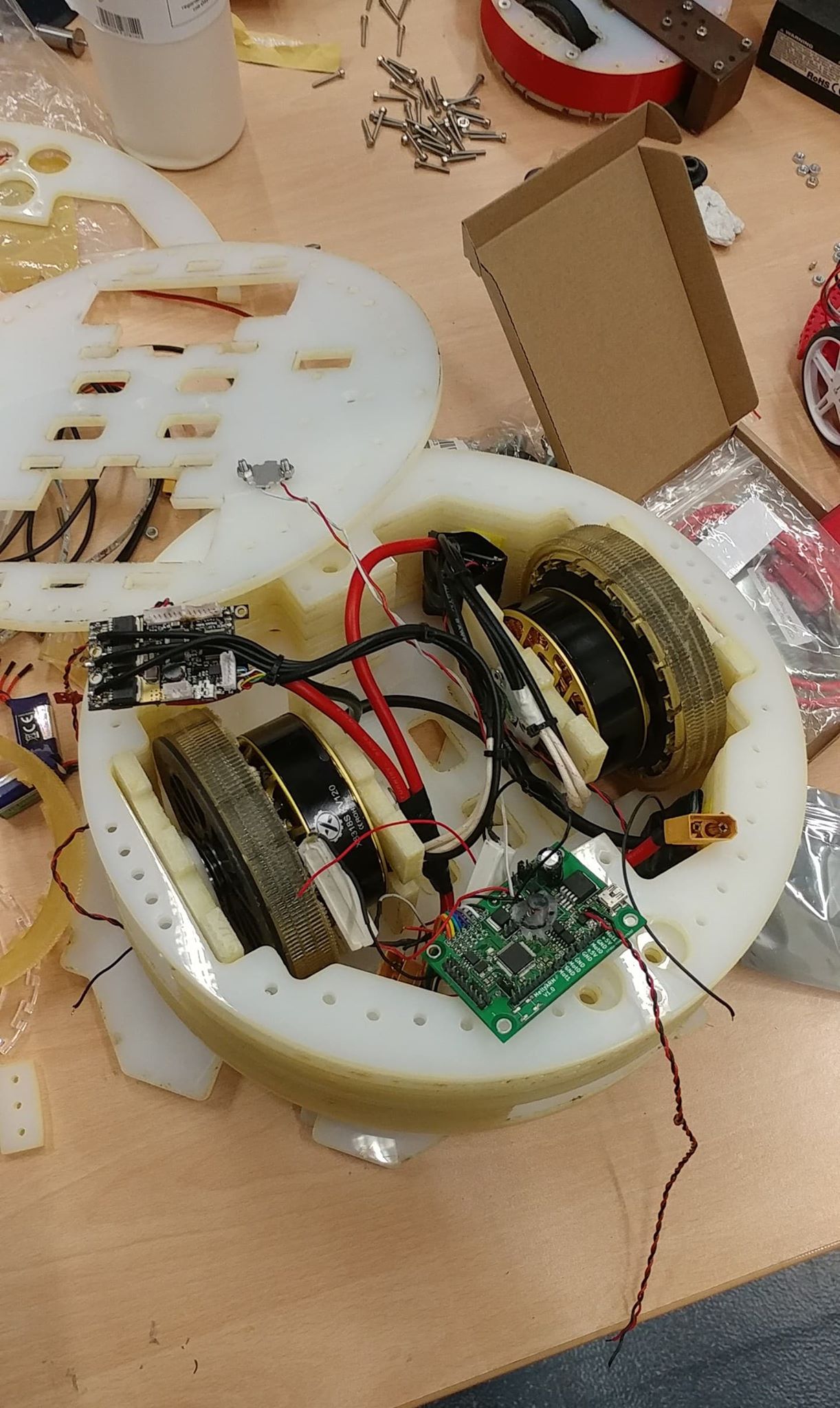

And now the whole thing wired up: (still using the same VESC motor controllers and my own "Melty-arm" controller PCB):

On the first test run the robot blew one speed controller and the main controller - an approximate cost of 50p / cm travel - even the Bugatti Veyron had me beat on running costs! One MCU transplant, a spare motor controller, and some more conservative current limit parameters later, it went for its second test:

Drive works nicely! the turning is very sensitive, so control is... limited... and it can skid it's wheels with no problem! The translational drift system is working very well without any tuning - I expect some big speed gains once I’ve tuned it a little as well as better stability after I add the heavy weapon bar!

Here it is, the finished robot:

TRAC had its first test outing at Extreme Robots Portsmouth. It was immobilized in both fights by signal wires to the encoders / speed controllers breaking upon impacts. It did manage a couple of (large) hits though so it will return with some fresh epoxied wires!

More to come as development continues...