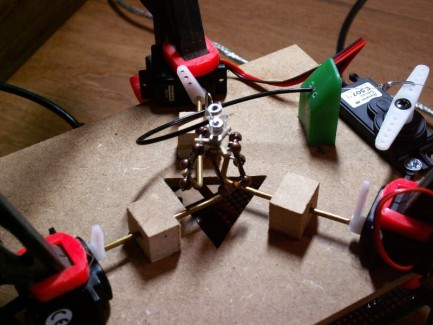

Tiny delta parallel robot

This is a delta parallel robot - aimed to be the smallest in the world. I aimed at a height of about 1cm, but during building I found that, with my limited-precision home tools, I could not achieve sufficient accuracy to reach that level of tiny-ness. Hence, its maximum reaching height is about 3cm.

A delta parallel robot of this type, used for quick pick-and-place applications, is usually built up of a base, upper arms, lower arms and the 'head', on which an actuator (arm, magnet, air suction) is mounted. For the base I used MDF; for ease of construction (and shed-availability :-) ). The upper arms are make of brass (availability in shed), steel needles (cut to 1cm) and tiny beads (from my wifes DIY jewelry box).

The arms are made of cupper bead-clamps (from an art/craft shop, used to attach things to beaded necklaces). Two soldered together form the arm that connects to the base, over the beads of the upper arms.

The head is created from pieces of brass and an M2 bolt for attaching actuators. Finally, the robot arms are powered by microservos (5 euro) by www.conrad.nl . The full robot (without an actuator) is shown here:

The robots movements are controlled by a Parallax Propeller RPM board - 5V is available, and the output pins deliver sufficient voltage for the signal lines.

Currently the software is written for a set of demo movements, see the first video - nothing intelligent yet. I'm working on a set of building blocks (objects) for the parallax propellor especially for delta robots; including calculation of conversion of x,y,z to servo-angles.

Now I'm stumbling on the actuator, to grab and release tiny objects. Magnetic? Suction? Actual gripper? I do not know yet how to make it tiny. Well, a tiny electromagnet is easy, but if I use a ferromagnetic core, I'm afraid the remanence will be too large to release small iron beads, for example. Will be testing this shortly. Any ideas?

And another step: making a user interface. Probably in LabWindows. How to input 3D movements for direct control? Any ideas?

Update may 2010:

Finally found some time to continue to the Gripper:

The gripper is made by simply bending a small piece of packaging plastic into a 'U' shape, and drilling two small holes opposing eachother. It is operated by a nylon wire in an isolation 'hose', compare it to handbrakes on a bike. A fourth servo pulls on the nylon wire to close the gripper.

The second video demonstrates the gripper operation. It grabs an M2 nut, swings it around, and puts it back into place.

Grabbing objects, swinging them around

- Actuators / output devices: 4 servos

- CPU: Parallax Propeller

- Power source: 6V

- Programming language: Spin, assemby